A preparation method of ferrite solid waste-based electromagnetic wave absorbing material doped with excessive zinc

A technology of absorbing materials and ferrite, which is applied in the direction of inorganic material magnetism, inductance/transformer/magnet manufacturing, circuits, etc., can solve the problems of aggravating electromagnetic interference of devices, device performance degradation, error reporting, etc., and achieve low equipment hardware requirements and production The effect of short cycle and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

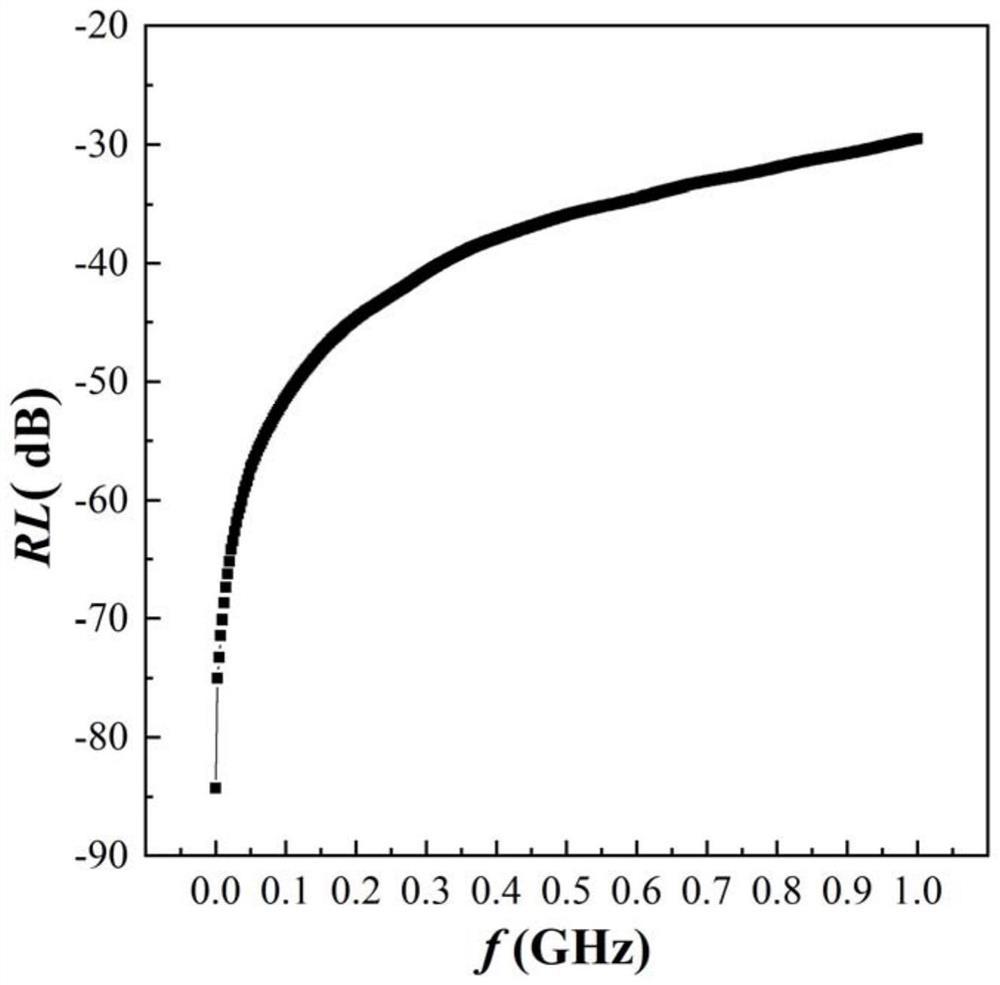

Embodiment 1

[0026] This embodiment uses soft magnetic ferrite solid waste as the precursor, which is mainly derived from grinding solid waste, waste magnetic core, waste generated in the production process of soft magnetic materials such as manganese zinc ferrite, nickel zinc ferrite and devices and devices Magnetic blanks, or crushed solid waste from waste ferrite cores in electronic waste, first purify soft ferrite solid waste by washing, dispersing, filtering, magnetic separation, etc., and then mix it with ferrite solid waste 10% zinc oxide is added, the mixed powder is ball-milled and pressed, and the pre-compact is heat-treated to prepare a ferrite solid waste-based broadband electromagnetic wave absorber. The specific preparation method includes the following steps:

[0027] Step 1: Purification of Soft Ferrite Solid Waste

[0028] 1a. Fully mix the soft ferrite solid waste powder with water, stir and disperse it, and then sieve to filter out some large metal chips, emery and other...

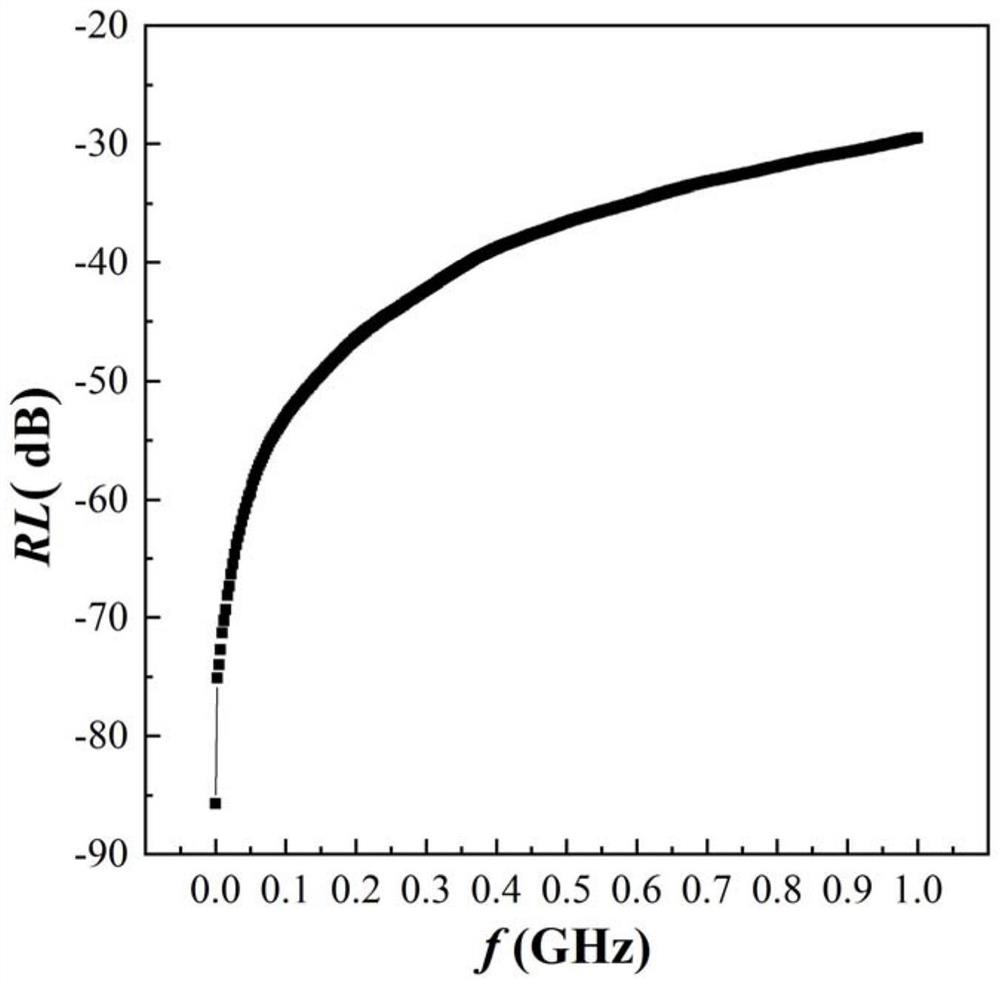

Embodiment 2

[0036]This embodiment uses soft magnetic ferrite solid waste as the precursor, which is mainly derived from grinding solid waste, waste magnetic core, waste generated in the production process of soft magnetic materials such as manganese zinc ferrite, nickel zinc ferrite and devices and devices Magnetic blanks, or crushed solid waste from waste ferrite cores in electronic waste, first purify soft ferrite solid waste by washing, dispersing, filtering, magnetic separation, etc., and then mix it with ferrite solid waste 14% zinc oxide was added, the mixed powder was ball-milled and pressed, and then the preform was heat-treated to prepare a ferrite solid waste-based broadband electromagnetic wave absorber. The specific preparation method includes the following steps:

[0037] Step 1: Purification of Soft Ferrite Solid Waste

[0038] 1a. Fully mix the soft ferrite solid waste powder with water and stir to disperse, then sieve to filter out some large metal chips, emery and other i...

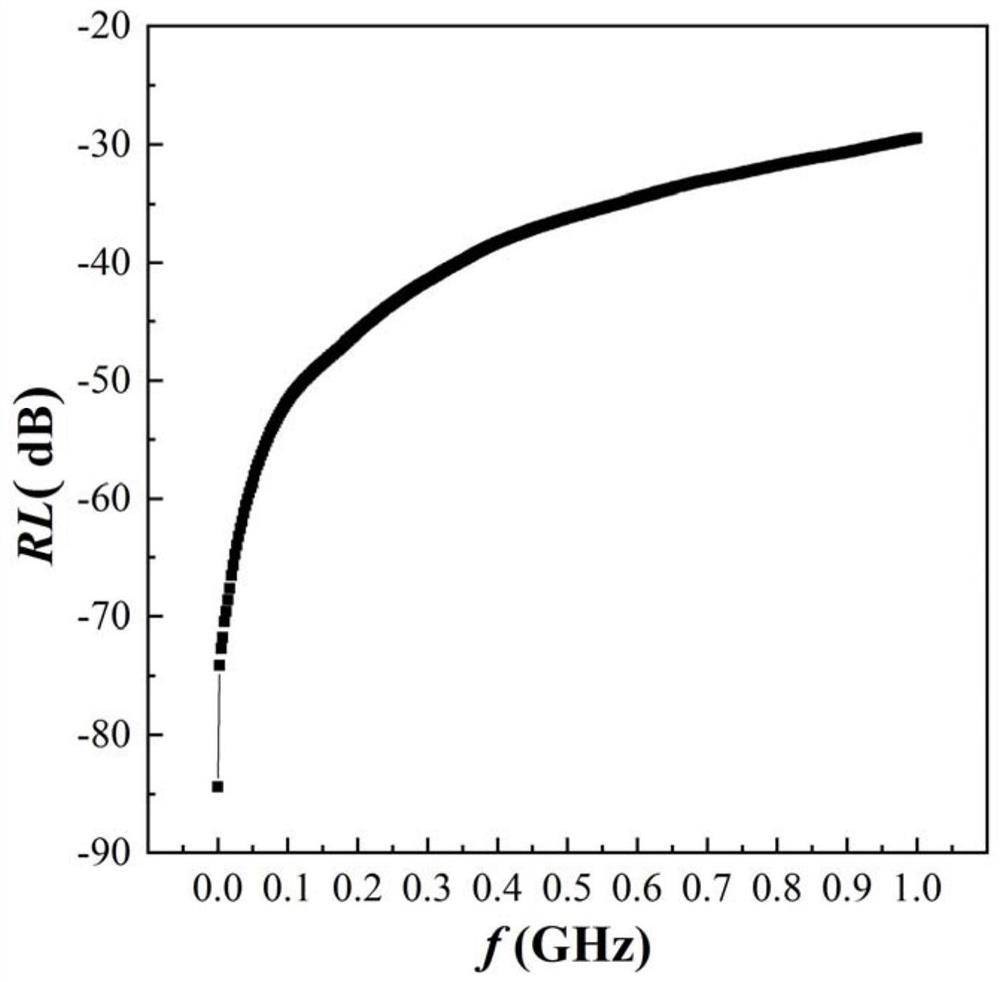

Embodiment 3

[0046] This embodiment uses soft magnetic ferrite solid waste as the precursor, which is mainly derived from grinding solid waste, waste magnetic core, waste generated in the production process of soft magnetic materials such as manganese zinc ferrite, nickel zinc ferrite and devices and devices Magnetic blanks, or crushed solid waste from waste ferrite cores in electronic waste, first purify soft ferrite solid waste by washing, dispersing, filtering, magnetic separation, etc., and then mix it with ferrite solid waste 20% zinc oxide is added, the mixed powder is ball-milled and pressed, and the pre-compact is heat-treated to prepare a ferrite solid waste-based broadband electromagnetic wave absorber. The specific preparation method includes the following steps:

[0047] Step 1: Purification of Soft Ferrite Solid Waste

[0048] 1a. Fully mix the soft ferrite solid waste powder with water and stir to disperse, then sieve to filter out some large metal chips, emery and other impu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com