Box body lifting structure of storage cabinet

A lifting structure and storage cabinet technology, applied in cabinets, adjustable cabinets, household appliances, etc., can solve the problems of inconvenient operation and inability to place items on storage racks, and achieve convenient operation, small external space, and good structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

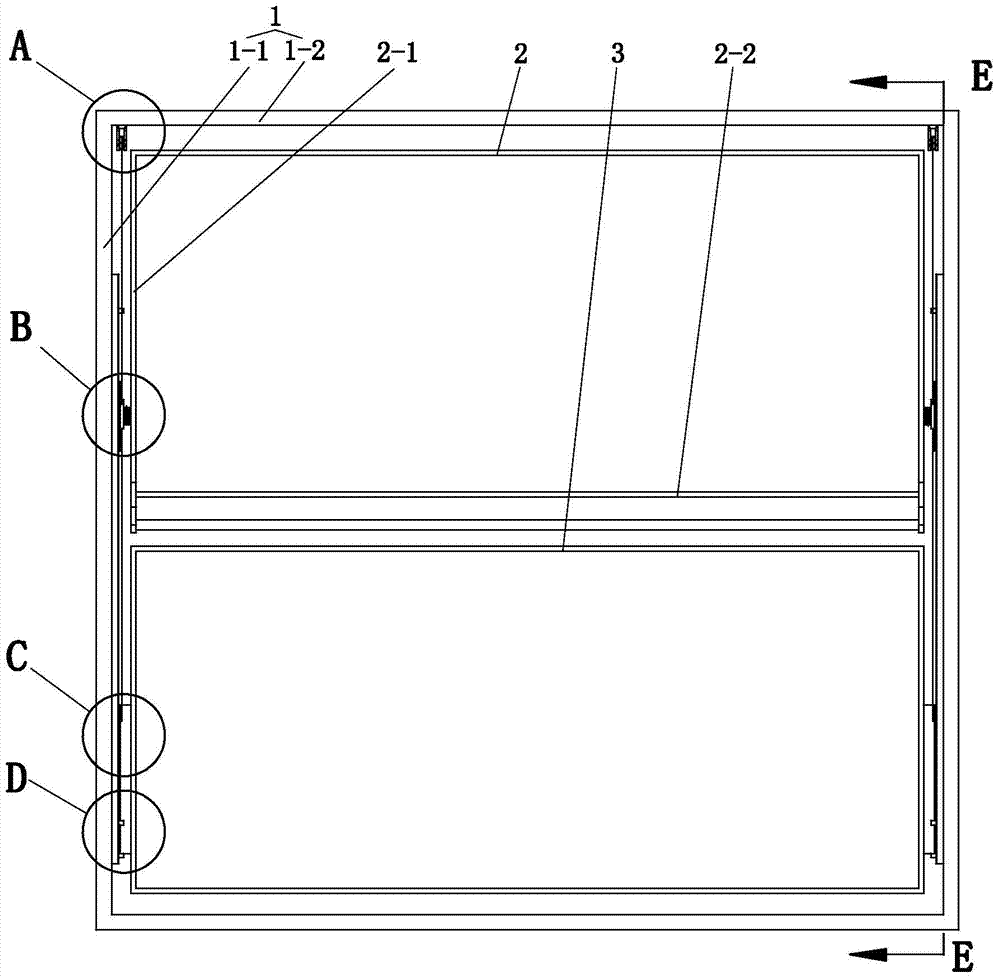

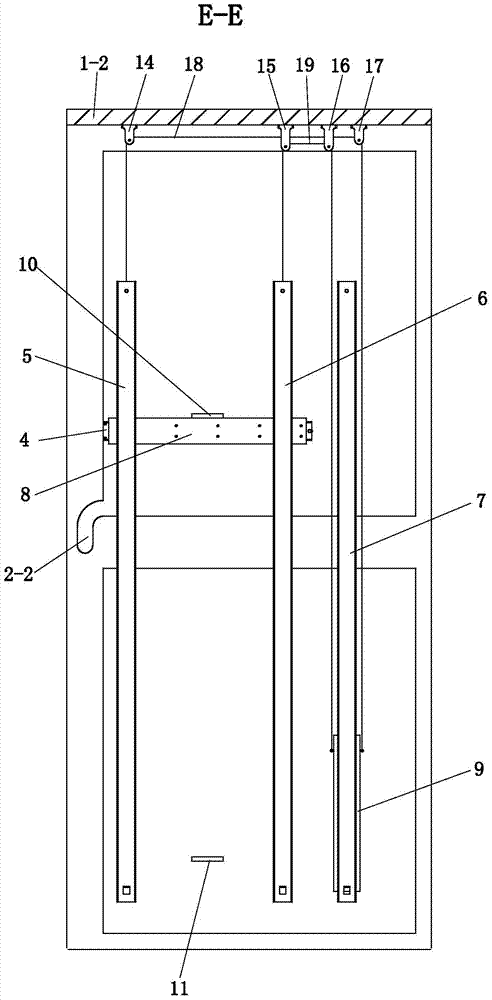

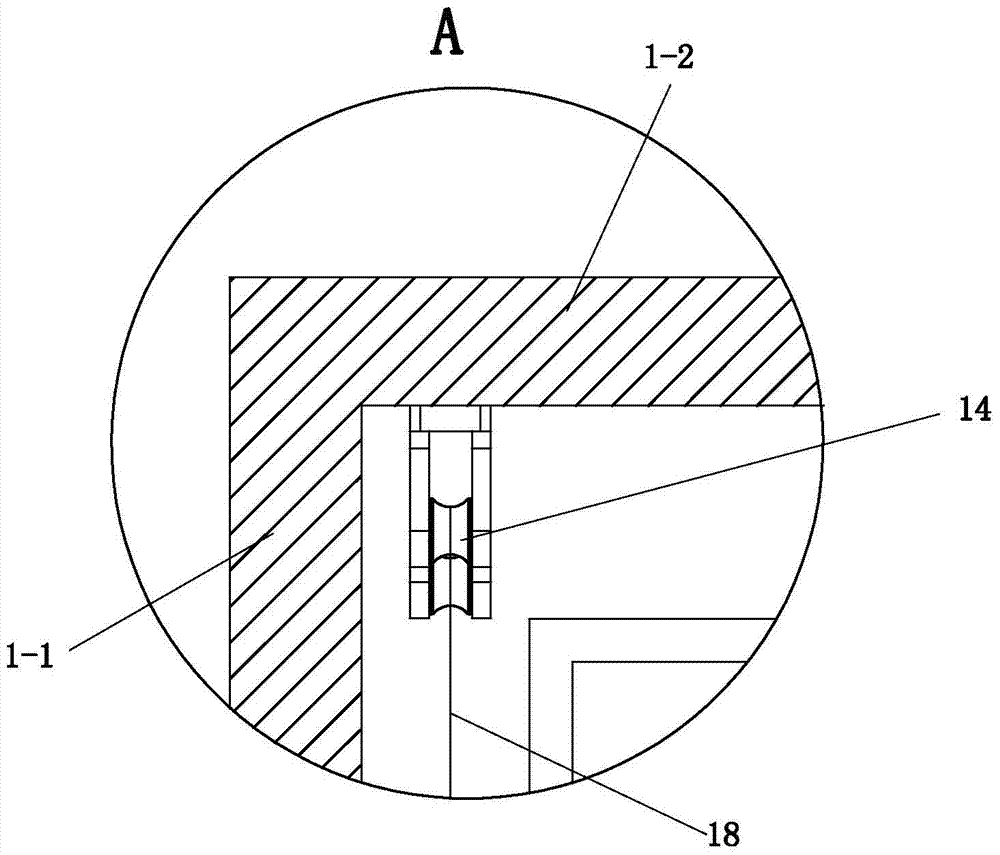

[0025] See Figure 1 to Figure 11 , The cabinet lifting structure of the locker in this embodiment has a cabinet body 1 and an active cabinet body 2 and a passive cabinet body 3 inside the cabinet body 1 . The active box body 2 is provided with a handle 2-2. The inboards of the left and right cabinet boards 1-1 of the cabinet body 1 respectively have a front vertical slide rail 5, a middle vertical slide rail 6, a rear vertical slide rail 7 and a horizontal telescopic slide rail 4.

[0026] The distance between the front vertical slide rail 5 and the middle vertical slide rail 6 is relatively large. The front vertical slide rail 5, the middle vertical slide rail 6, and the rear vertical slide rail 7 have the same structure, all of which have a vertical guide groove S and a vertical slide bar T matching the vertical guide groove S. There is a ball Q between the vertical guide groove S and the vertical guide bar T, and the ball Q is supported by the ball support Q-1 (see Fig...

Embodiment 2

[0034] See Figure 12 , the present embodiment is not to limit the stroke of the front lifting plate, but to limit the stroke of the rear lifting plate, so the magnetic upper and lower limit blocks of the front lifting plate are not provided. On the inner sides of the two cabinet boards 1-1 on the left and right of the cabinet body 1 and at the upper limit position of the rear lifting plate, a rear lifting plate magnetic upper limit block 12 is respectively provided, and a rear lifting plate magnetic upper limit block 12 is respectively provided at the lower limit position of the rear lifting plate. Lifting plate magnetic lower limit block 13. When the lower end of the rear lifting plate 9 hits the magnetic lower limit block 13 of the rear lifting plate, or the upper end surface of the rear lifting plate 9 touches the magnetic upper limit block 12 of the rear lifting plate, stop pulling (pushing) the active box body 2 . All the other are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com