Simple car body sheet metal stretching correction equipment

A correction equipment and simple technology, applied in the field of automobile sheet metal maintenance, can solve the problems of reducing the tension requirement, large movable clearance, reducing the clamping mechanism, etc., to increase the safety factor, ensure the connection strength, and reduce the height effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

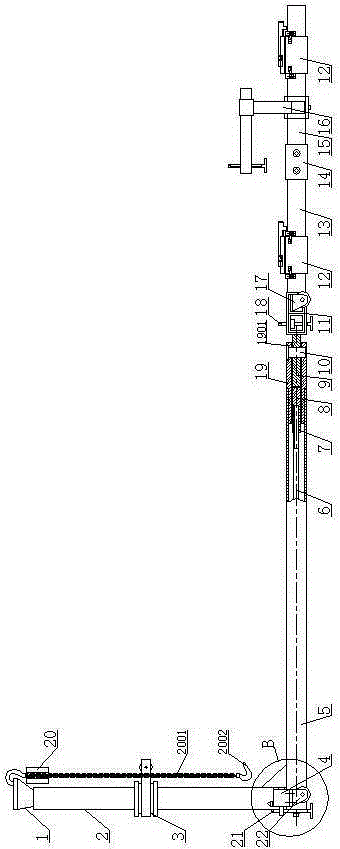

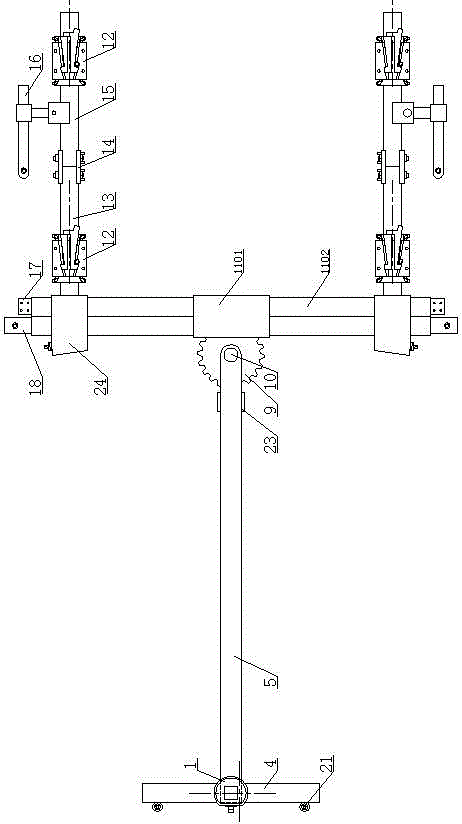

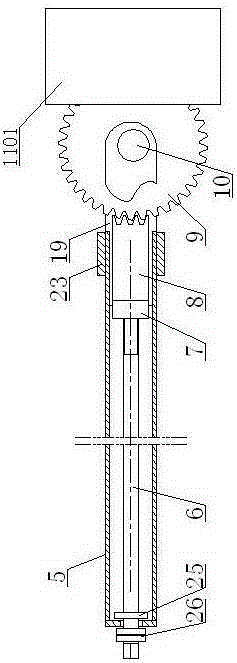

[0047] As shown in the figure, the simple automobile body sheet metal tension correction equipment includes a main pull tower 2, a hanger 1 arranged on the top of the main pull tower 2, and a chain hoist 20 hung on the hanger 1 , the traction guider 3 that is located in the middle of the main pull tower 2 and is used to adjust the height of the chain block 20 zipper, the horizontal beam 5 that is fixed on the lower end of the main pull tower 2 and is perpendicular to it, the support frame hinged with the horizontal beam 5, and is located on the support The clamping mechanism on the frame and the equipment traveling mechanism.

[0048] Wherein, the horizontal beam 5 is built with a positioning rod 6, and one end of the positioning rod 6 is threadedly connected with a positioning nut 7 that reciprocates along the inner wall of the horizontal beam 5, and the front end of the positioning nut 7 is welded with a positioning tooth plate with a tooth surface 8. The other end of the po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com