Fast return punching buffer device and hydraulic press for punching and blanking

A cushioning device and blanking technology, applied in metal processing equipment, safety equipment, manufacturing tools, etc., can solve the problems of low working efficiency of hydraulic press, slow down speed of main oil cylinder, slow return speed of main oil cylinder and buffer cylinder, etc., to achieve Reduced idle travel time, small body vibration, and good cushioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

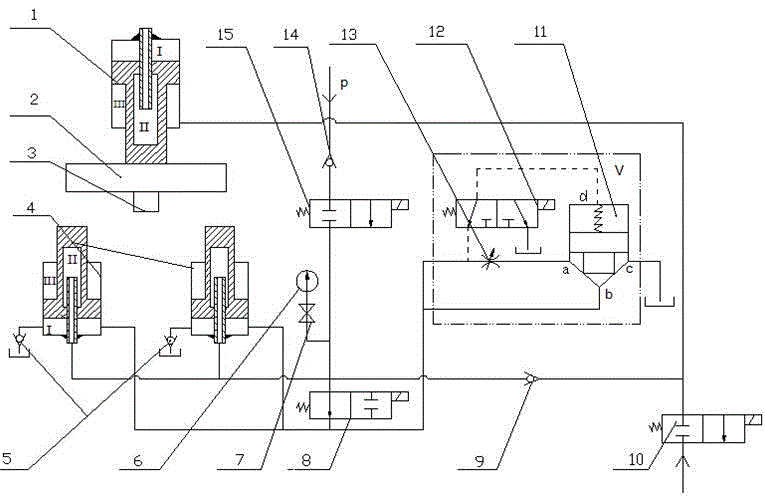

[0016] Such as figure 1 As shown, in the idle stroke when the piston rod of the main cylinder 1 moves downward, the main oil circuit fills the chamber I of the main oil cylinder 1 with oil to make it go down quickly. Cavities Ⅰ and Ⅱ are filled with oil at the same time to provide sufficient punching force; when the slider 2 reaches the punching buffer point, the two-position two-way electromagnetic reversing valve 15 is energized, and the punching pressure signal p passes through the two-position two-way electromagnetic The reversing valve 15 and the two-position two-way solenoid valve 8 enter the I and II cavities of the buffer cylinder 4 so that the buffer cylinder 4 quickly builds up a sufficiently large buffer force and acts on the slider 2. At the same time, the I and II cavities of the buffer cylinder 4 The oil is discharged into the oil tank after passing through the ports a and c of the adjustable throttle valve 12 and the two-way cartridge valve 11, and the adjustabl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap