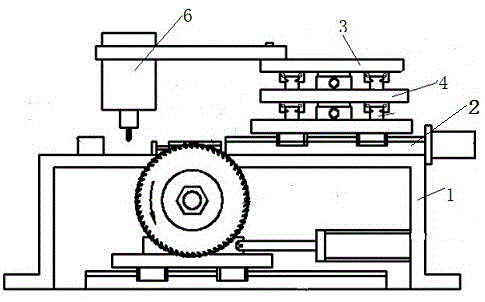

Automatically adjusted electronic radiator processing equipment and processing method

A processing equipment and automatic adjustment technology, applied to other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of affecting the adjustment of tapping position and destroying the "drilling-tapping center distance" state, so as to save adjustment time and manpower The effect of friendly computer interaction and strong vitality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

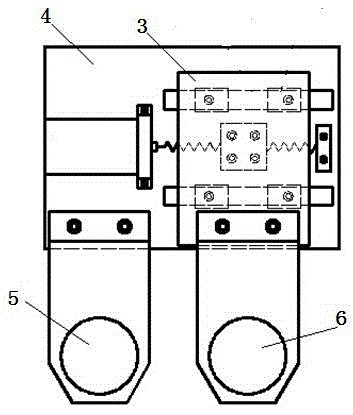

Method used

Image

Examples

Embodiment

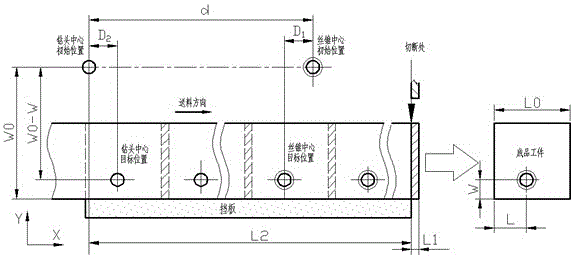

[0031] The first step is to measure the initial parameters of the machine tool, that is, to input the tool setting parameters:

[0032] The X-direction distance L2 from the center of the drill bit to the cutting point = 200mm;

[0033] The distance in X direction from the center of the drill bit to the center of the tap = 135mm;

[0034] The distance in the Y direction from the center of the drill bit to the edge of the baffle W0=40mm;

[0035] To the touch screen, the PLC will save the data in the corresponding data register;

[0036] The second step is to enter the workpiece parameters:

[0037] Workpiece length L0=29mm;

[0038] The distance L from the center of the hole to the left edge of the workpiece = 19mm;

[0039] Saw blade thickness L1=1mm;

[0040] The distance from the center of the hole to the side edge of the workpiece near the baffle W=20mm;

[0041] To the touch screen, the PLC will save the data in the corresponding data register;

[0042] In the third s...

Embodiment 2

[0051] On the basis of implementation 1, the distance from the center of the workpiece hole to the left edge of the workpiece is changed to 24mm, and the other dimensions remain unchanged. Using the method described above, only need to move X 下 5mm in the positive direction of the axial direction X means that the drilling position moves 5mm in the positive direction of X, and X 上 The adjustment and positioning can be completed without changing the positions of the axis and the Y axis, which is simple, fast, time-saving and efficient.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com