Automatic control system of plastic pipe chipless cutting machine

An automatic control system and plastic pipe technology, applied in metal processing and other directions, can solve the problems of obvious saw marks, sawdust generation, waste of raw materials and other problems in the incision, to ensure effective stroke feed speed, convenient switching, and high degree of automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

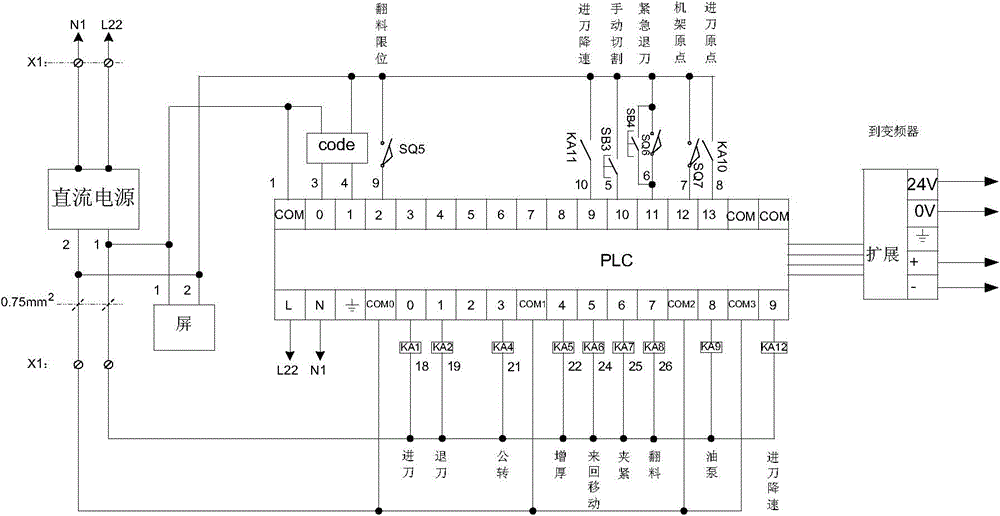

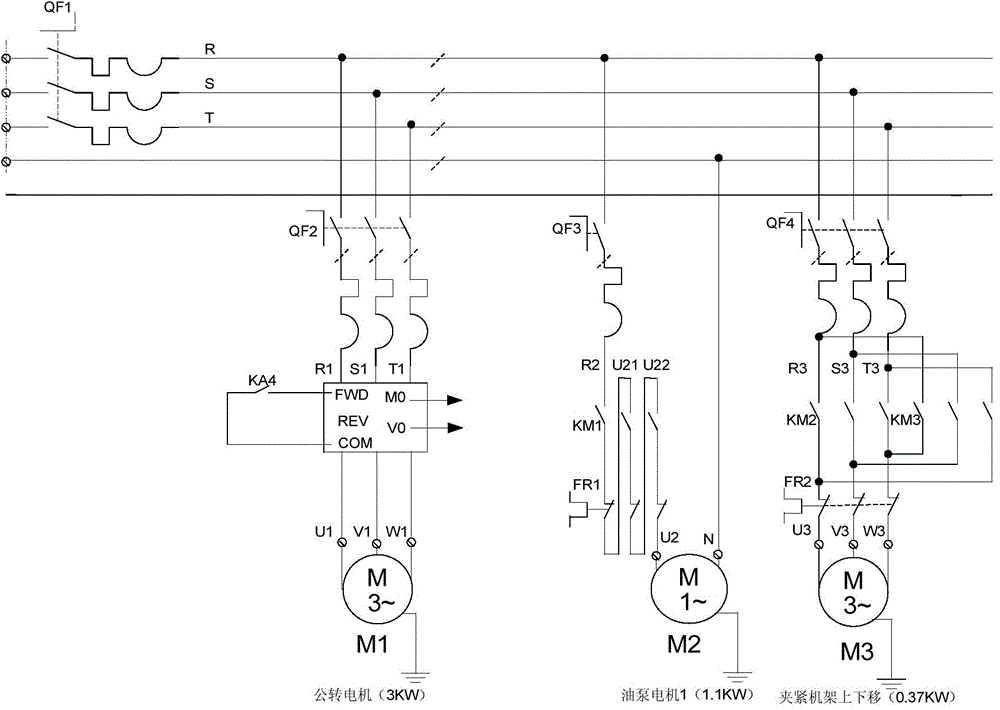

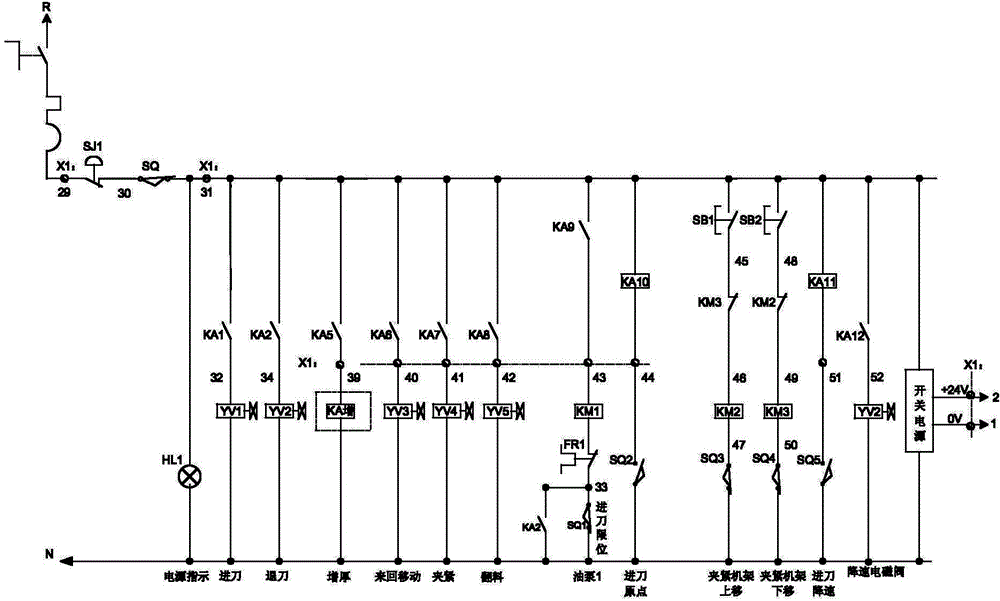

[0024] Such as Figure 1-3 As shown, an automatic control system for a plastic pipe chipless cutting machine includes a DC power supply, a touch screen, an encoder, PLC and control subsystems at all levels, and the DC power supply is connected to the touch screen, encoder, PLC and control subsystems at all levels respectively. System connection, the PLC shown is respectively connected with the touch screen, the encoder, and the control subsystems at all levels. The control subsystems at all levels include the revolution system control part of the cutting machine, the servo system control part, the cutting system control part and the clip The clamping system control part, the PLC sequentially controls the clamping system control part, the revolution system control part, the servo system control part, and the cutting system control part to complete the cutting.

[0025] The encoder measures the length of the pipe, and when the length of the pipe reaches the set requirement, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com