A motorcycle production line

A technology for production lines and motorcycles, applied in metal processing, assembly machines, metal processing equipment, etc., can solve the problems of increasing logistics links in production lines, covering a large area of production lines, and being unsuitable for multiple varieties, so as to improve space utilization and save money. The effect of occupying area and saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

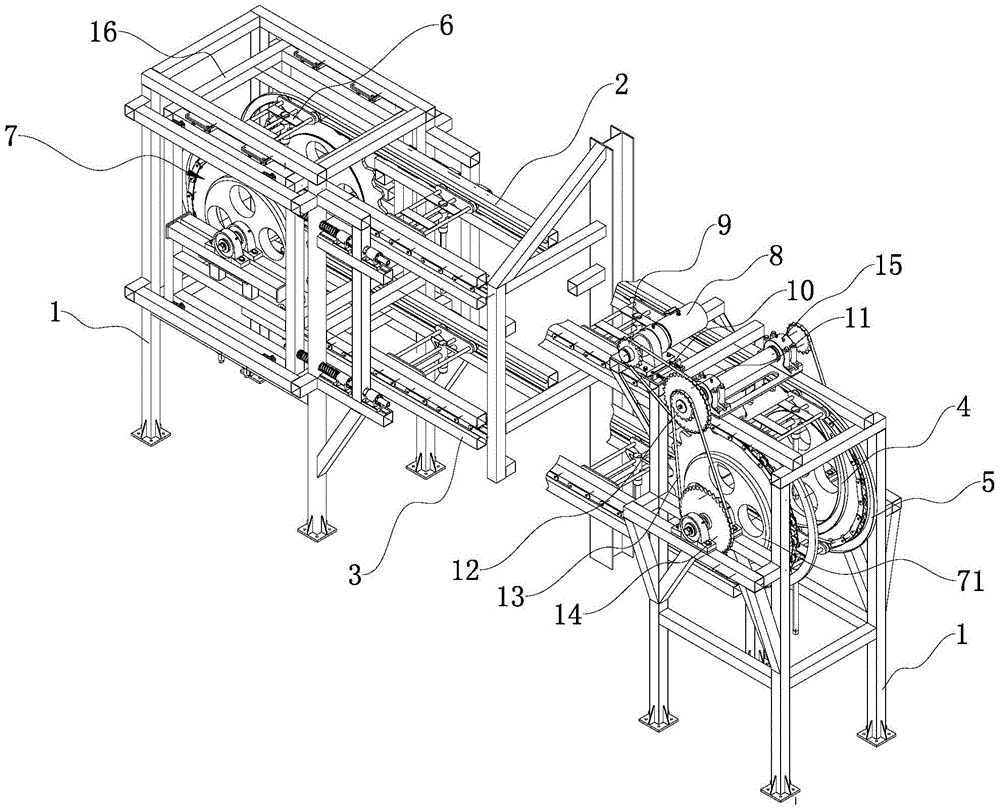

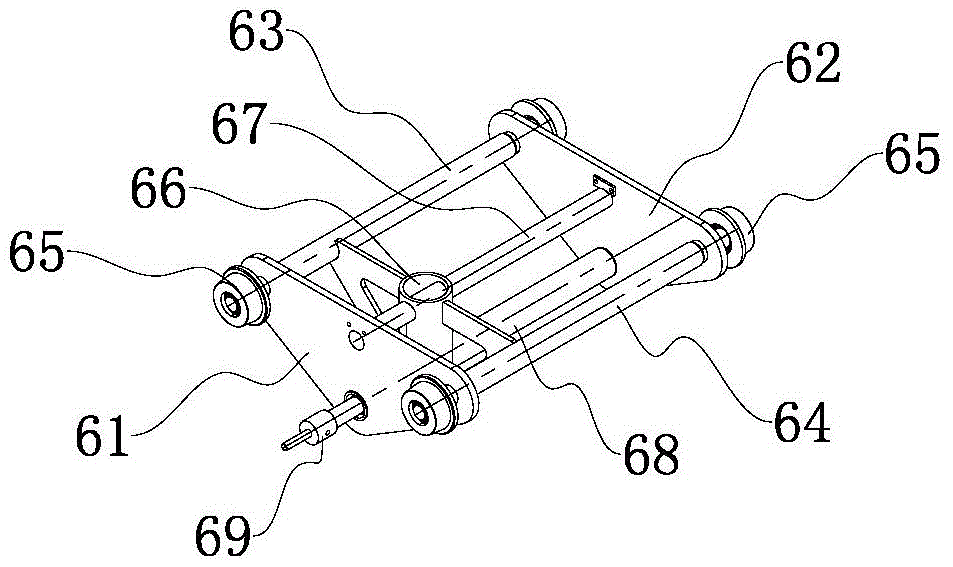

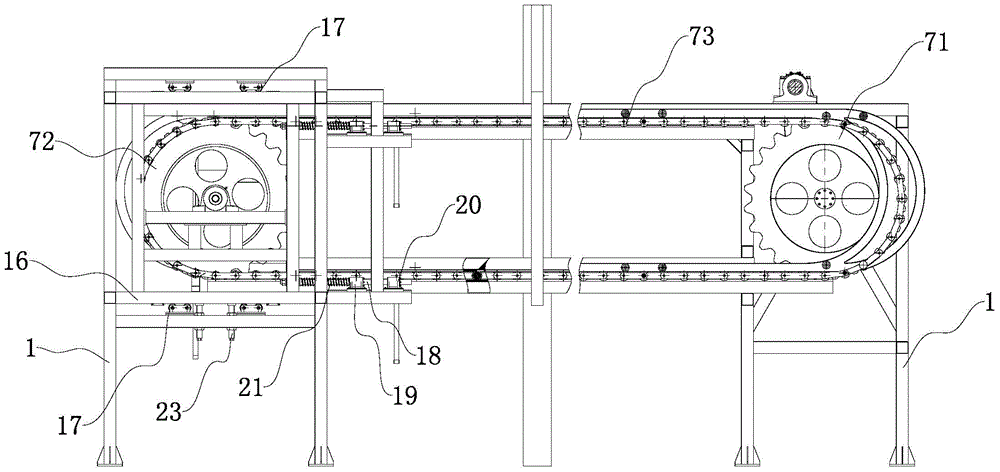

[0016] refer to figure 1 , a motorcycle production line of the present invention, comprising a frame 1, upper and lower traction guide rails 2, 3 are respectively installed on the frame 1, and inner and outer arcs are respectively arranged at both ends of the upper and lower traction guide rails 2, 3 Shaped transition guide rails 4,5, the inner and outer arc transition guide rails 4,5 respectively connect the corresponding ends of the upper and lower traction guide rails, the upper and lower traction guide rails 2,3 and the inner and outer arc transition guide rails 4 , 5 form the circulation guide rail circuit, the suspension mechanism 6 that can move along the circulation guide rail circuit is arranged in this circulation guide rail circuit, the assembly workbench that can lift is installed under this suspension mechanism 6, also is installed on the described circulation guide rail circuit A chain transmission mechanism 7 that drives the movement of the suspension mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com