An elastic cylindrical pin assembly tooling

A technology of elastic cylindrical pins and assembly tooling, applied in the direction of manufacturing tools, hand-held tools, etc., can solve the problems of low assembly efficiency and inability to achieve continuous assembly, and achieve the effect of improving assembly efficiency and continuous assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

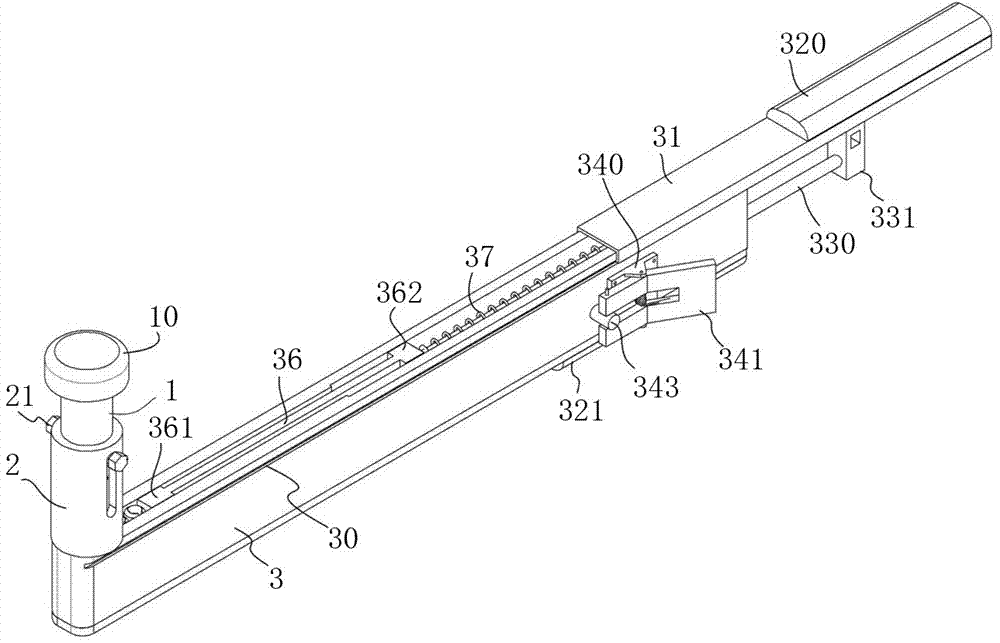

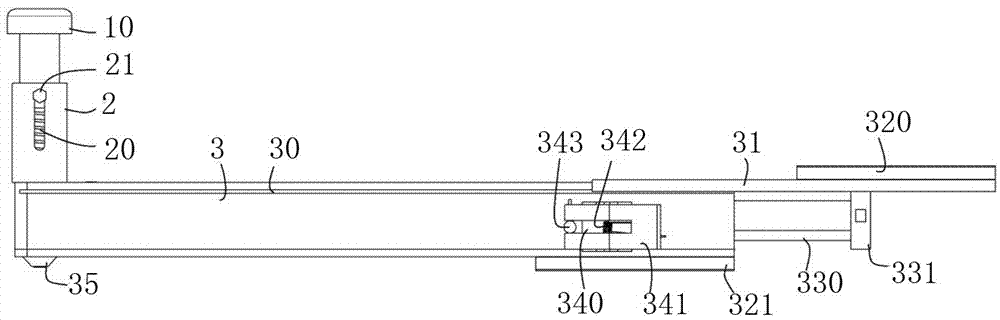

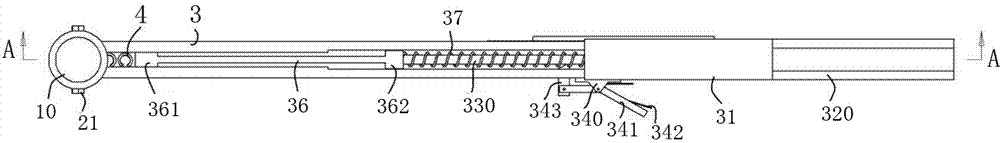

[0021] Embodiment one of the elastic cylindrical pin assembly tooling of the present invention: as Figure 1-5 As shown, it includes a main body and a thimble 1 that guides and moves up and down relative to the main body. In this embodiment, the main body includes a fixed sleeve 2 and a handle arm 3 disposed below the fixed sleeve 2 .

[0022] The fixed sleeve 2 extends in the up and down direction, and the thimble 1 is guided and moved in the up and down direction to be assembled in the fixed sleeve 2. The lower end of the fixed sleeve 2 is provided with a thimble hole for the thimble 1 to protrude downward. In this embodiment, the fixed sleeve The lower end of the barrel is provided with an inturned edge, and the thimble 1 is a stepped shape with a large upper part and a smaller lower part. The large-diameter section at the upper end of the thimble pin 1 is guided and moved with the inner peripheral surface of the fixed sleeve 2 in the up and down direction, and the small-dia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com