Intelligent rubber mixing process of open mill

An open mill and rubber mixing technology, which is applied in the field of rubber processing, can solve the problems of reduced physical and mechanical properties and wear resistance of rubber materials, inability to guarantee the quality of rubber mixing, waste of energy, etc., to save parking time, with obvious effects and control simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

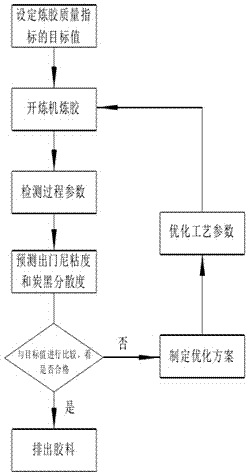

[0022] The technological process of the present invention is carried out on laboratory XK160. Such as figure 1 As shown, using the all-steel radial tire tread rubber as the rubber material, the model of Mooney viscosity and dispersion is firstly predicted, and the experimental data of the all-steel radial tire tread rubber is used, and the correlation analysis software SPSS is used to analyze Carry out correlation analysis, and get the process parameters that are highly correlated with Mooney viscosity to be transverse pressure F and debinding temperature T, and solve the parameters to be estimated =56.308, =1.471, =-0.301, =0, =0 ; get the process parameter with a large correlation with dispersion as the unit energy consumption N, and solve the parameter to be estimated =4.144, =0, =0, =0, =3.422

[0023] . Set the target values of rubber mixing quality indicators such as Mooney viscosity and carbon black dispersion: take Mooney viscosity of 60 and car...

Embodiment 2

[0025] The technological process of the present invention is carried out on laboratory XK160. Such as figure 1As shown, using all-steel radial tire tread rubber, firstly predict the Mooney viscosity and dispersion model, using the experimental data of all-steel radial tire tread rubber, and using the correlation analysis software SPSS to analyze Carry out correlation analysis, and get the process parameters that are highly correlated with Mooney viscosity to be transverse pressure F and debinding temperature T, and solve the parameters to be estimated =56.308, =1.471, =-0.301, =0, =0 ; get the process parameter with a large correlation with dispersion as the unit energy consumption N, and solve the parameter to be estimated =4.144, =0, =0, =0, =3.422. Set the target values of rubber mixing quality indicators such as Mooney viscosity and carbon black dispersion: take Mooney viscosity of 60 and carbon black dispersion of 6, set the initial value of rubber ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| force | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com