Repair method for tire wound and repair method for tire bulge wound

A technology for wounds and tires, applied in tires, applications, household appliances, etc., can solve problems such as complex procedures, reduced compressive strength, loss of reinforcement and airtight effects, etc., to achieve the effect of expanding the repair range and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment A pair of sidewall wound repair, the tire to be repaired is a truck tire that has been used for 1 year, the wound and the cord are at an angle of 85 degrees, and the length of the wound is 85mm.

[0032] The maximum safe repair wound size of the sidewall is 100mm along the vertical cord direction. If there is an angle between the wound and the cord, it shall be calculated based on the projected size of the wound in the vertical cord direction, but the actual repair size of the wound shall not exceed 150mm. .

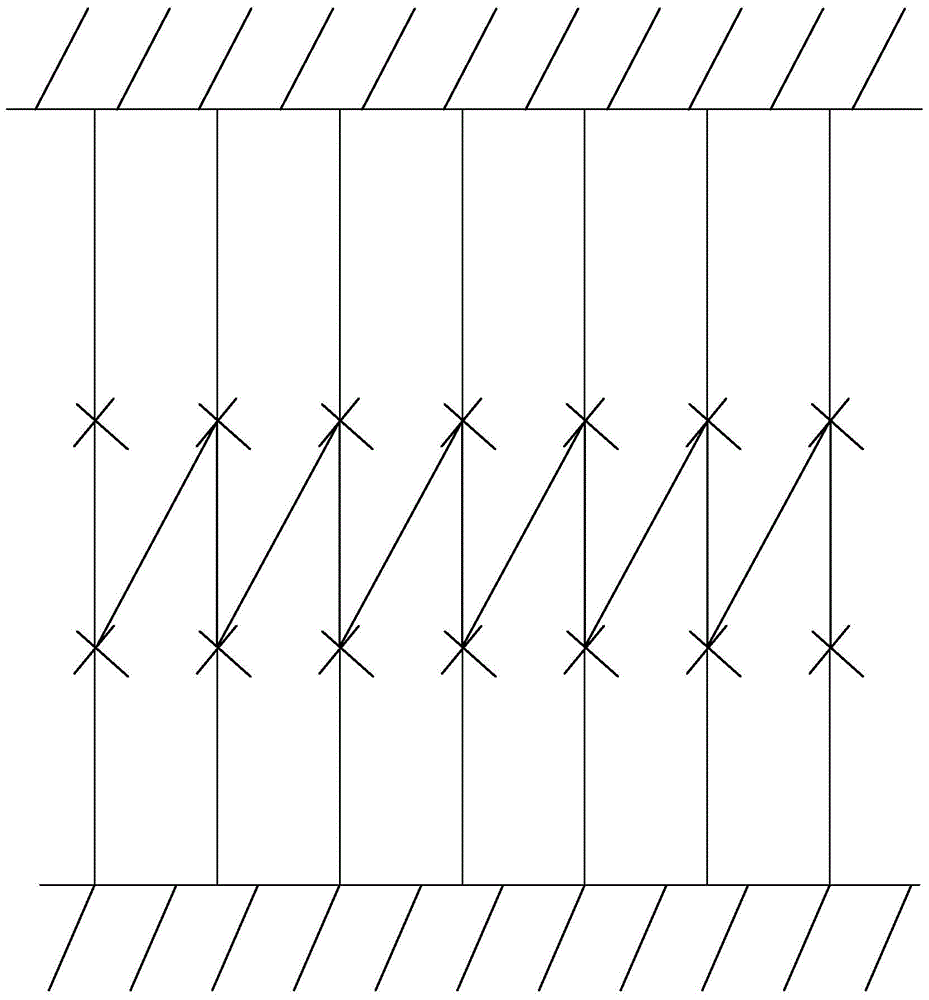

[0033] Refer to attached figure 1 , this embodiment includes the following steps:

[0034] A. Tire expansion: remove the tire wound and the surrounding dust, oil and impurities, and use the tire expansion machine to open the broken part of the tire;

[0035] B. Grinding exposed lines: Grind the area on both sides of the fracture wound with a hand grinder. The grinding area is 15-25mm on both sides of the wound. Grind off all the rubber on both sides t...

Embodiment 2

[0043] The mending of embodiment two tire top wounds, the long 45mm of wounds

[0044] The maximum safe repair wound size of tire roof is 50mm along the broken line direction

[0045] The tire to be repaired is a 2.5-year-old car tire, the steel wire is not damaged, the wound is 35mm long and 10mm deep

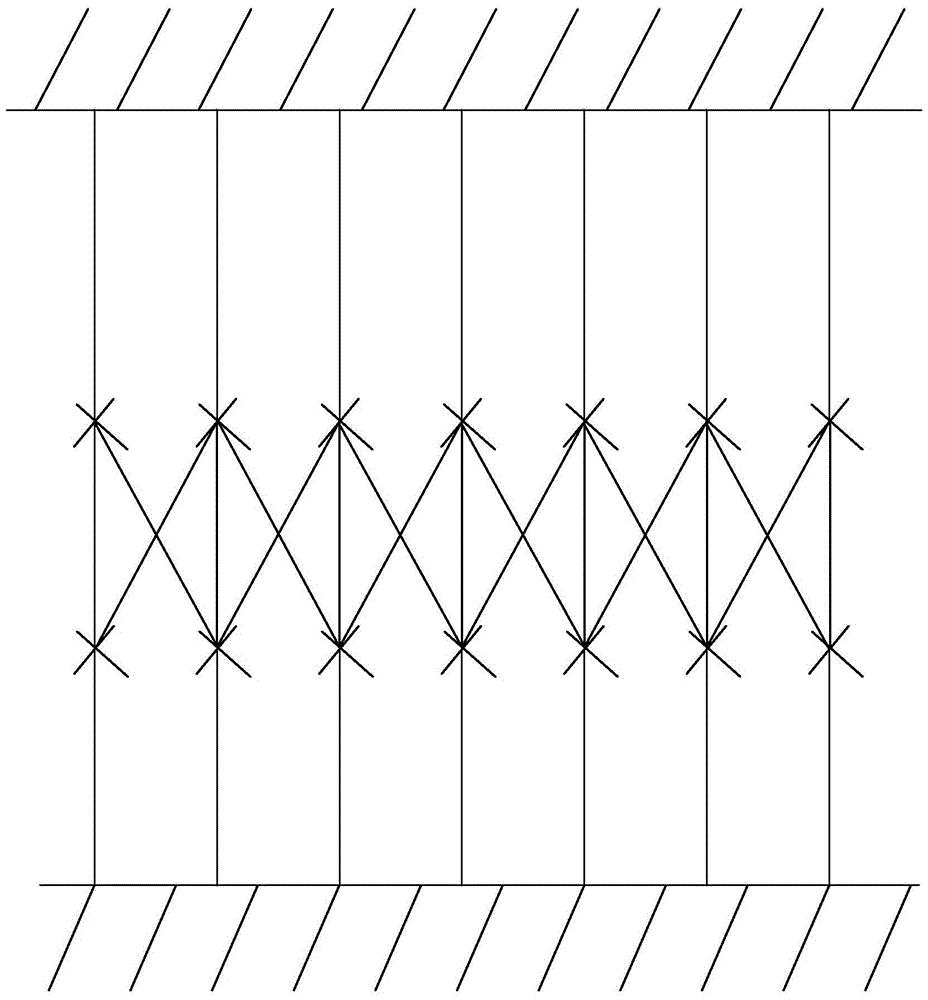

[0046] The repairing method of this embodiment is basically the same as that of Embodiment 1, except that what is used in the "D, wiring" step is a multi-connection knotting method. The multi-knotting method refers to combining 2 or 3 broken thread ends on the same side of the wound by tying a dead knot, so that two rows of knots extending along the wound are formed on both sides of the wound, Each knot forms a knot loop, that is, the 2 or 3 broken threads that make up the knot are connected to form a closed knot loop, so that two rows of knots are formed on both sides of the wound. Head thread loop; take a new thread of sufficient length, tie one end of the new thread to th...

Embodiment 3

[0047] Example 3 Repair of sidewall wounds. The tire to be repaired is a truck tire that has been used for half a year. The wound and the cord form an angle of 30 degrees, and the length of the wound is 95 mm.

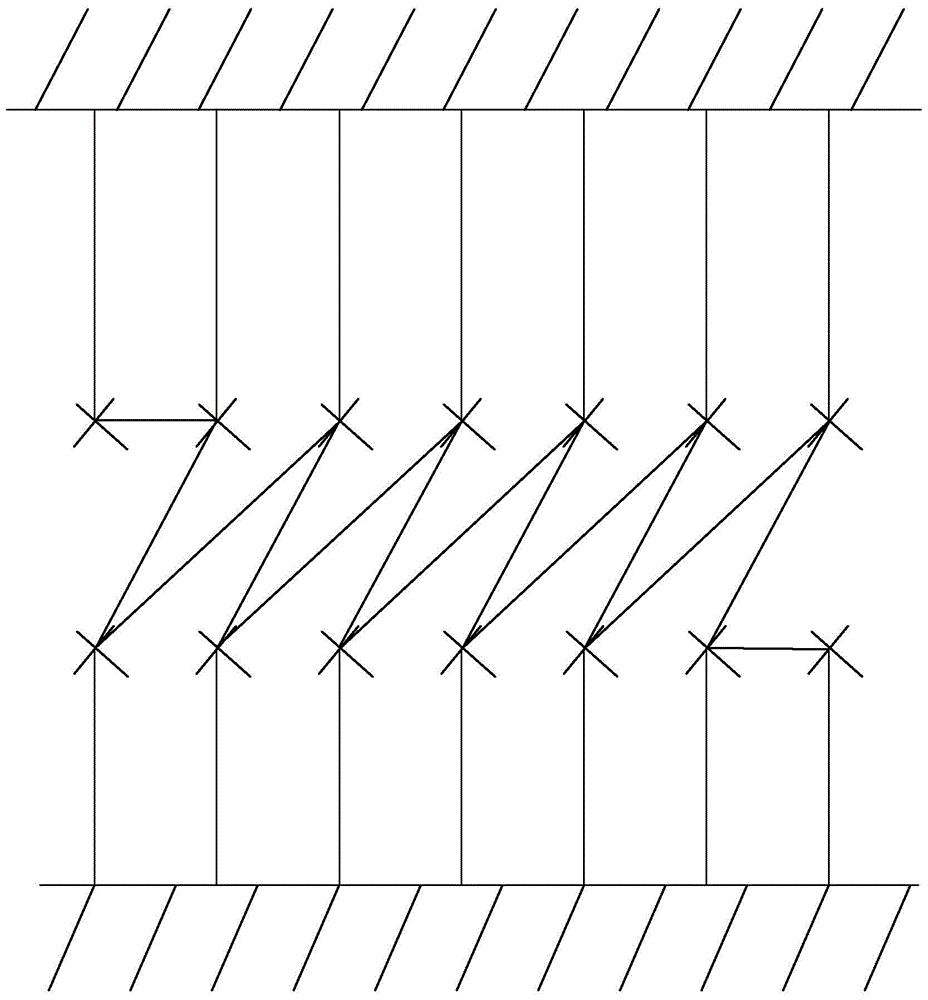

[0048] refer to figure 2 , The repairing method of this embodiment is basically the same as that of Embodiment 1, the difference is that what is used in the "D, wiring" step is the dislocation connection and knotting method. The dislocation connection knotting method is to stagger one or two broken thread ends on both sides of the wound to connect, and use a new thread to connect the first broken thread end on one side of the wound with the second or second thread end on the other side of the wound. The three broken thread ends are connected with a dead knot, and then the long end of the new thread is wound back to the wound on one side and connected with the second broken thread end, and then the long end of the new thread is wound to the other side of the wound and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com