Catapult window breaking device

A ejection-type, window-breaking technology, which is applied in transportation and packaging, pedestrian/passenger safety arrangement, vehicle safety arrangement, etc., can solve the problems of large space, short effective force arm, easy loss, etc. The effect of long arm and short start-up time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

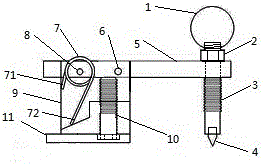

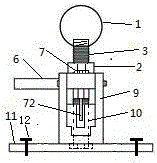

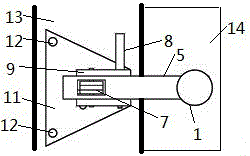

[0024] like figure 1 , 2 , The ejection-type window breaking device shown in 3 is composed of a spherical handle 1, a nut 2, a screw rod 3, a striker 4, a rotating arm 5, a safety pin 6, a torsion spring 7, a pin 8, a bearing 9, an inner hexagon socket screw 10, The triangular base 11 and the screw 12 are characterized in that the spherical handle 1 is threaded and screwed to the upper end of the screw 3, the screw 3 is threaded and the front end of the rotating arm 5 is screwed, the nut 2 is set on the screw 3, and is located between the rotating arm 5 and the spherical In the middle of the handle 1, the rivet 4 is embedded in the lower end of the screw rod 3, the tip of the rivet 4 touches the window glass surface, the rear end of the rotating arm 5 is fixed with the support 9 through the pin 8, and the pin 8 passes through the support 9 and the torsion spring 7 , rotating arm 5, safety pin 6 passes bearing 9, rotating arm 5, and the upper leg 71 of torsion spring is stuck ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com