Novel upper wall pier and trunk channel based large corrugated bulkhead product oil tanker

A technology for product oil tankers and large tanks, which is applied to hull bulkheads, hulls, and hull components. It can solve problems such as difficult construction, complex structural design, and poor economic efficiency of ships, and achieve low construction difficulty for personnel, simple structural design, and smooth ship construction. Environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

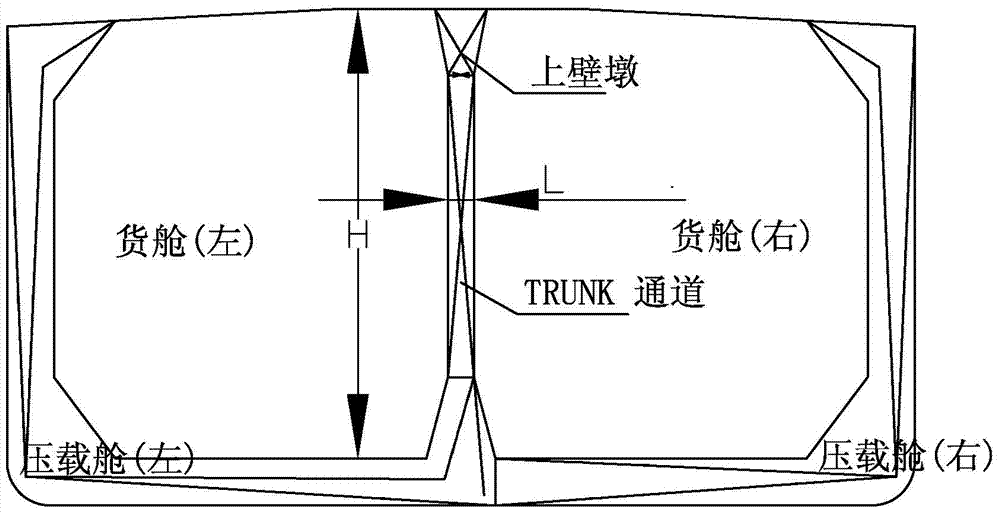

[0016] The design type of the upper wall pier and the trunk channel of the large trough bulkhead product oil tanker of the present invention adopts an empty cabin: the ratio of the width L of the channel of the trunk to the height H of the cargo hold is between 1% and 35%, see the attached figure 1 As shown, the specific requirements for the design type of the upper wall piers and trunk channel voids of the new large trough bulkhead product oil tanker are as follows: 0.01≤L:H≤0.35.

[0017] Taking a certain type of 110,000-ton product oil tanker P as an example, the design of the new upper wall pier and the trunk channel is as follows. The width L of the trunk channel is about 1.2 meters, the height H of the cargo tank is about 19.2 meters, and the ratio of L to H is about 6.25%.

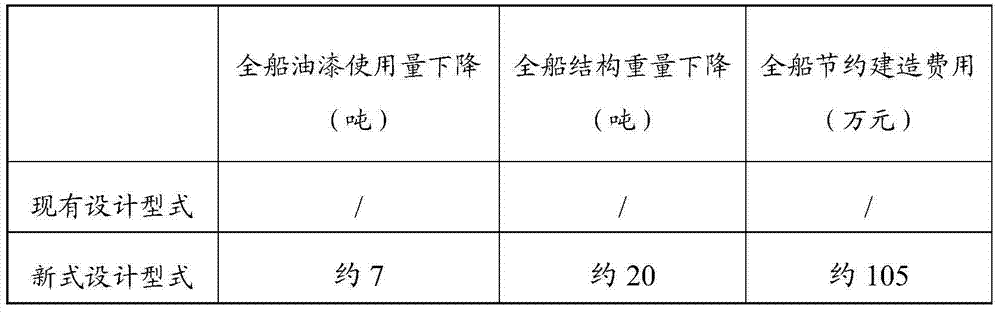

[0018] Compared with the existing designs of the upper pier and the ballast tank of the TRUNK channel of ships with corrugated bulkheads, the advantages of the new design of the upper pier and the Tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com