Air-assisted ultrasonic secondary atomization variable-particle-size atomizing sprayer

A technology of secondary atomization and ultrasonic atomization, which is applied in the device, application, animal husbandry and other directions of capturing or killing insects, can solve the problems of inability to produce pest control effects, affecting the absorption of medicinal liquid, and losing pest control effects, etc. Achieve the effect of inhibiting excessive pesticide residues, small environmental pollution, and adjustable droplet size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

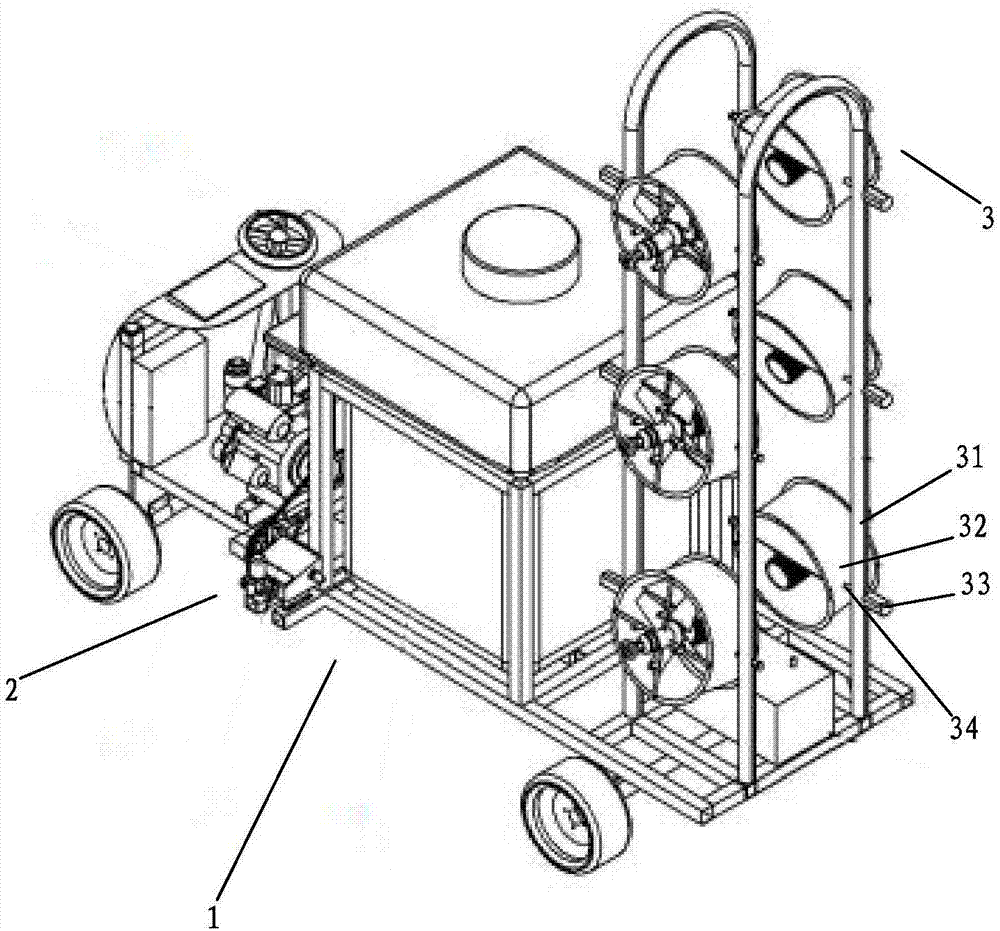

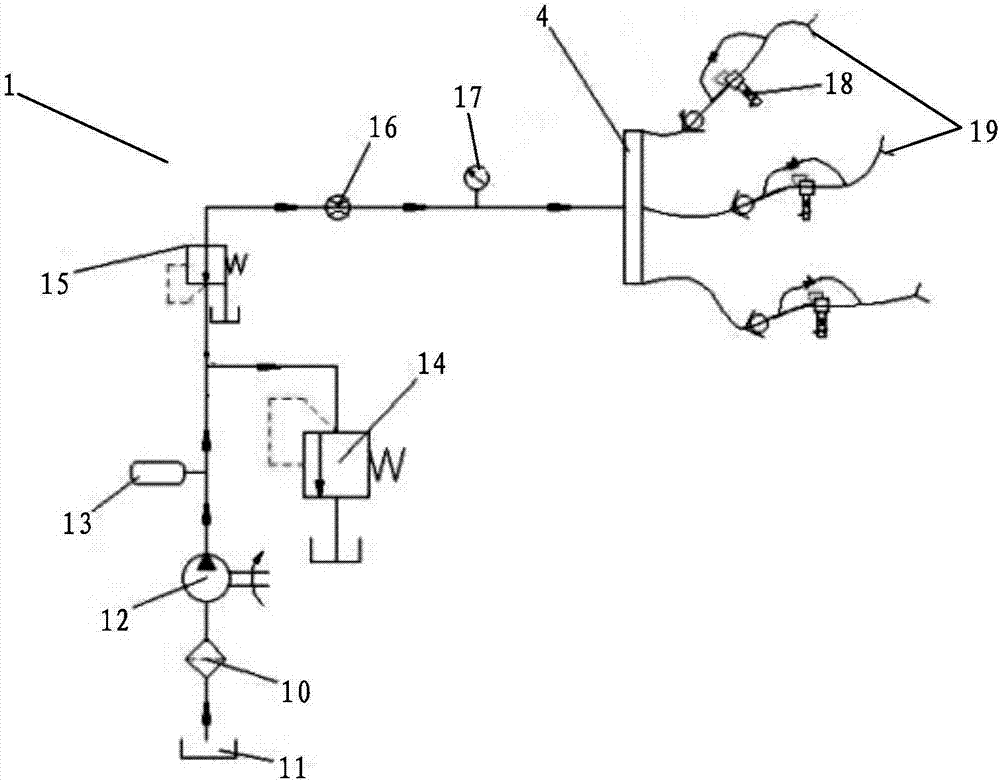

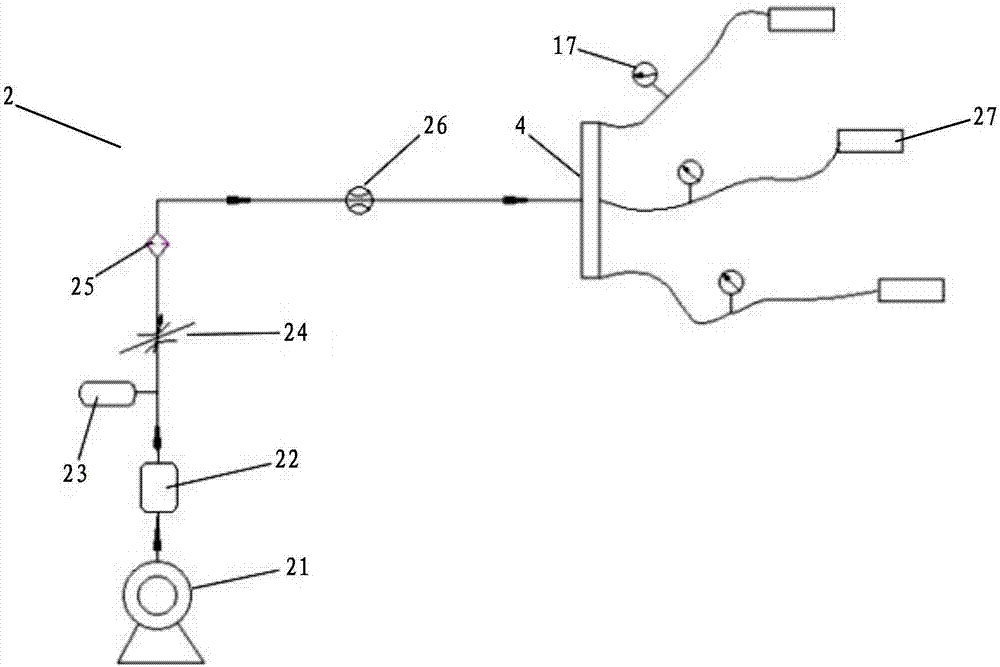

[0028] refer to Figure 1 to Figure 3 , the present embodiment relates to a sprayer, including a liquid medicine spraying system 1, an ultrasonic atomization system 2 and an air supply system 3, and the liquid injection port of the liquid medicine spray system 1 is arranged at the air outlet of the air supply system 3 , the ultrasonic output port of the ultrasonic atomization system 2 is facing the liquid spray port of the chemical liquid spraying system 1 to re-atomize the atomized chemical liquid sprayed from the liquid spray port.

[0029] The liquid medicine spraying system 1 of this structure atomizes and sprays the medicine liquid, and at the same time uses an ultrasonic system to perform secondary oscillation and atomization on the medicine liquid atomized and sprayed from the medicine liquid spraying system 1, so that the atomized liquid The droplet size is smaller than the atomization particle size of the nozzle. When the liquid spraying system 1 adjusts the spraying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com