Novel lifting antiskid transmission rail

A new type of anti-skid transmission technology, applied in the direction of conveyors, mechanical conveyors, conveyor objects, etc., can solve the problems of low transportation efficiency, difficulty in ensuring the smooth transportation of parts, and easy sliding of the transported parts, so as to improve transportation efficiency. , to ensure stability and prevent wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

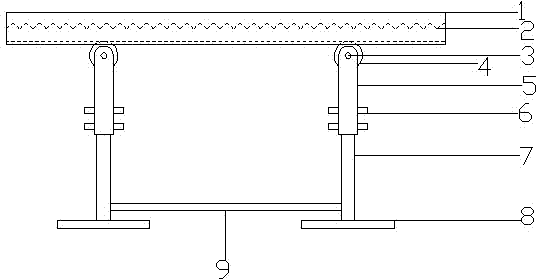

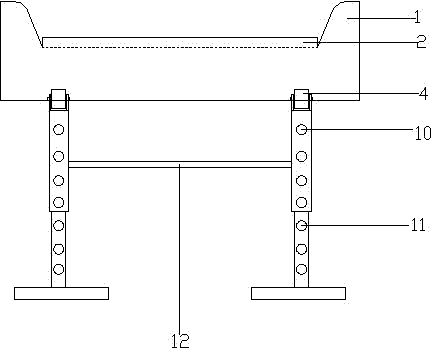

[0027] Such as figure 1 and figure 2 As shown, a new type of lifting anti-slip transmission track, including a transmission plate 1, is characterized in that it also includes an anti-skid plate 2, a pulley 4, a sleeve 5, a sleeve column 7, a base 8, a first connecting rod 9 and a second connecting rod 12. The upper surface of the transmission plate 1 is a trapezoidal concave surface, and the two sides of the lower surface are provided with anti-skid plates 2 along the transmission direction; the first threaded holes 10 arranged at equal intervals are arranged on one side of the sleeve 5, and the bearings 3 Connect with the pulley 4, the top of the pulley 4 is tangent to the lower surface of the anti-skid plate 2; the pulley 4 has N pieces, N is an integer, and is evenly distributed on the bottom of the anti-skid plate 2; the sleeve column 7 is provided with The first threaded hole 10 on the sleeve 5 corresponds to N second threaded holes 11 of equal size, and the two a...

Embodiment 2

[0031] Same as embodiment 1, the difference is that the number of threaded holes on the sleeve 5 and the sleeve column 7 are both three, which can ensure a more stable transmission plate.

Embodiment 3

[0033] The same as the embodiment 1, the difference is that the number of threaded holes on the sleeve 5 and the sleeve 7 are both 5, which can adjust the height in a wider range.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com