Test stand and method for ultra-deep mine hoisting systems

A lifting system and test bench technology, applied in elevators, transportation and packaging, etc., can solve problems such as difficult testing of lifting equipment, and achieve the effects of simple operation, safety protection, and easy maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with specific embodiments.

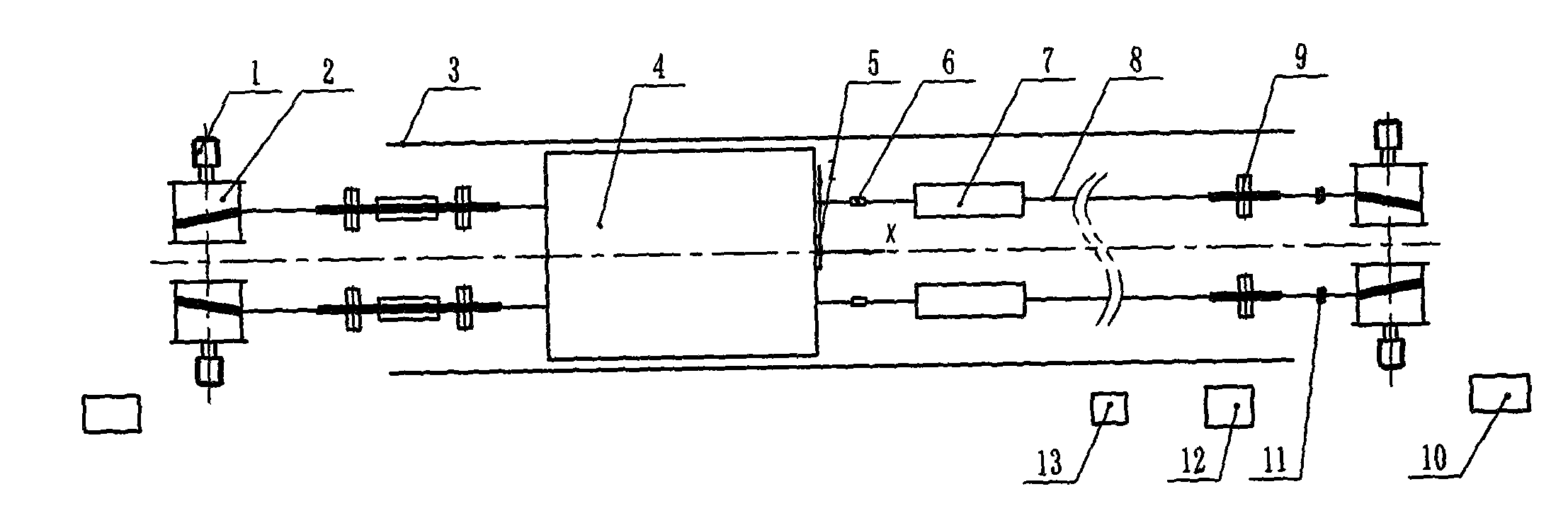

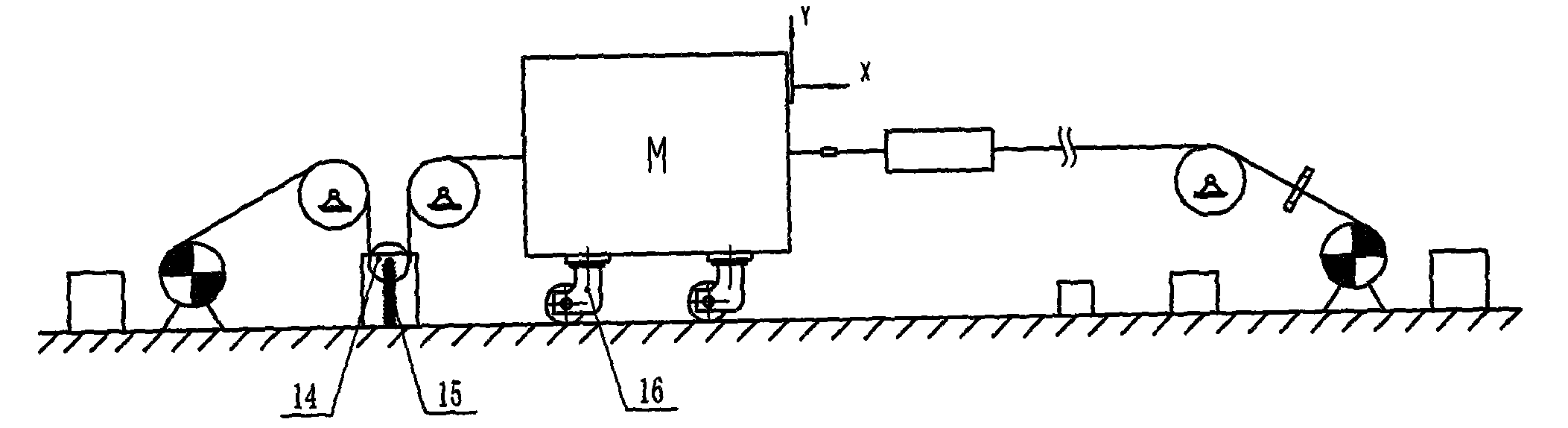

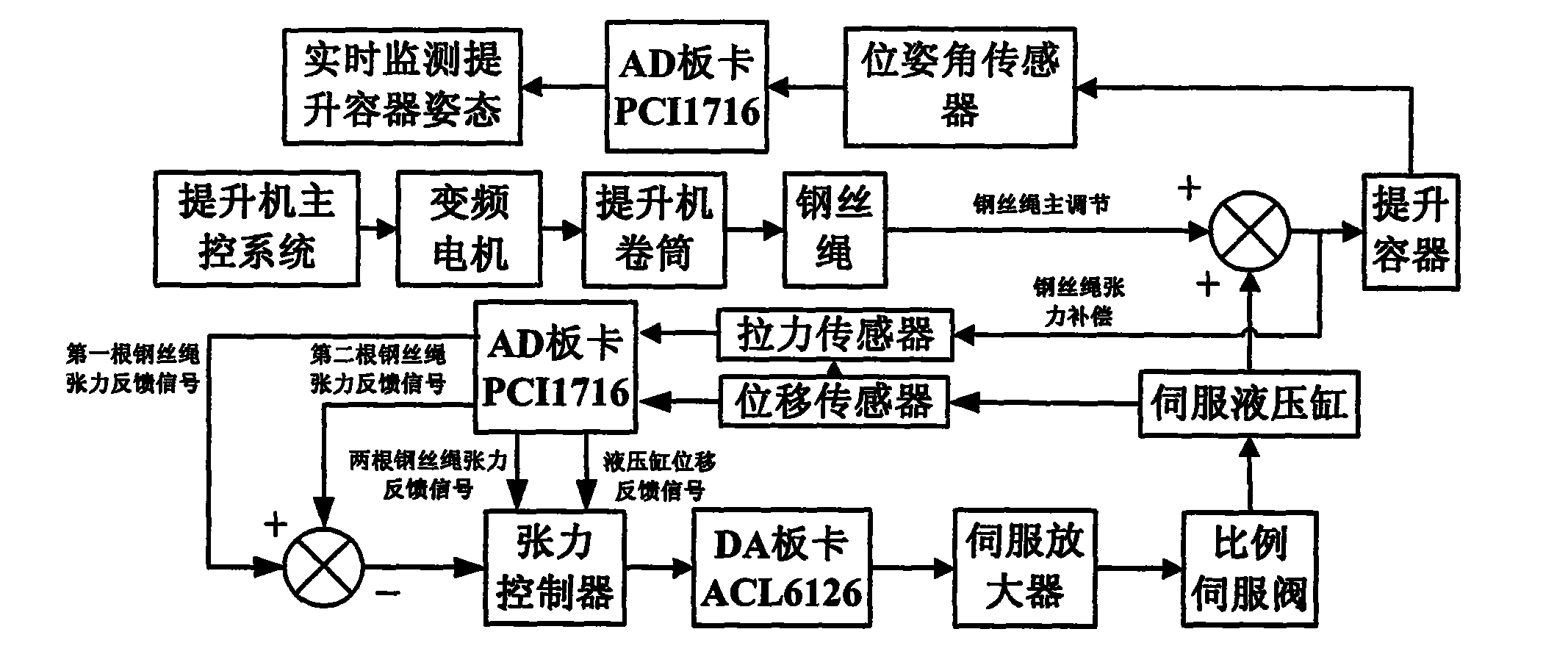

[0022] refer to figure 1 with figure 2 As shown, a test bench for an ultra-deep mine hoisting system includes four variable frequency motors (1) and four corresponding hoist drums (2), horizontal guide rails (3), hoisting container (4), and a pose angle Sensor (5), tension sensor (6), servo hydraulic cylinder (7), steel wire rope (8), pulley (9), frequency conversion motor controller (10), wire rope broken wire and strand broken detection device (11), servo hydraulic cylinder Controller (12), posture monitoring device (13), tensioning wheel (14), tensioning spring (15), universal wheel (16); lifting container (4) passes through the universal wheel (16) at its bottom Placed on a horizontal plane, the horizontal guide rails (3) are distributed on both sides of the lifting container (4) along the center line of the test bench to limit the swing of the lifting container 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com