Construction technology of slag stacking behind concrete faced rock-fill dam

A technology of face rockfill dam and construction technology, applied in dams, barrages, weirs, etc., can solve the problems of poor physical and mechanical properties, large amount of slag yard protection works, large water catchment, etc., so as to reduce the distance of waste slag transportation , the effect of increasing amusement facilities and beautifying the environment of the dam area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

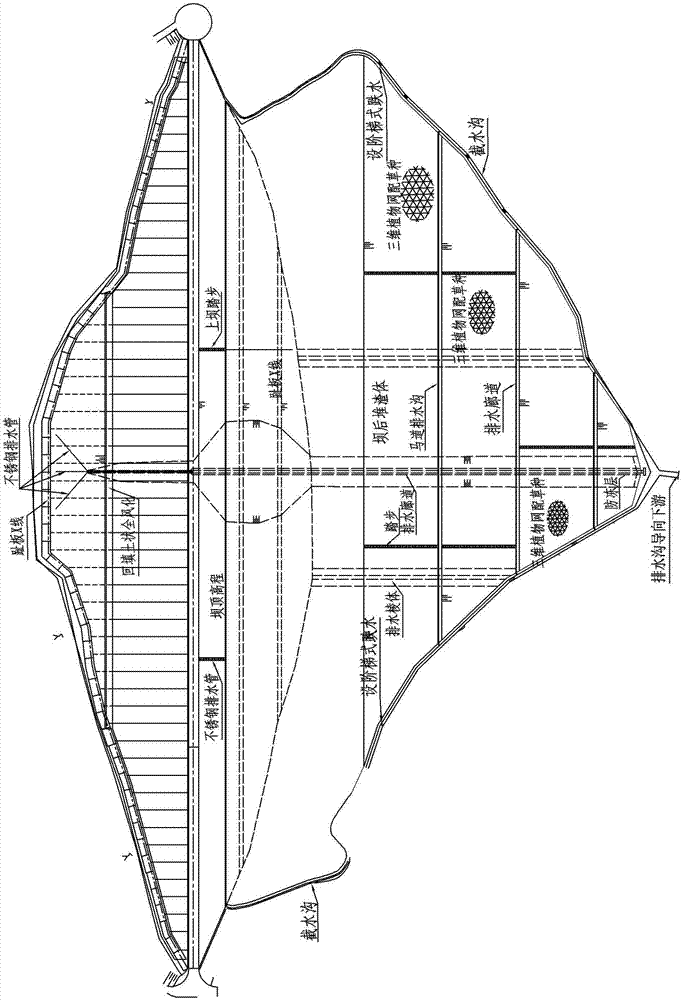

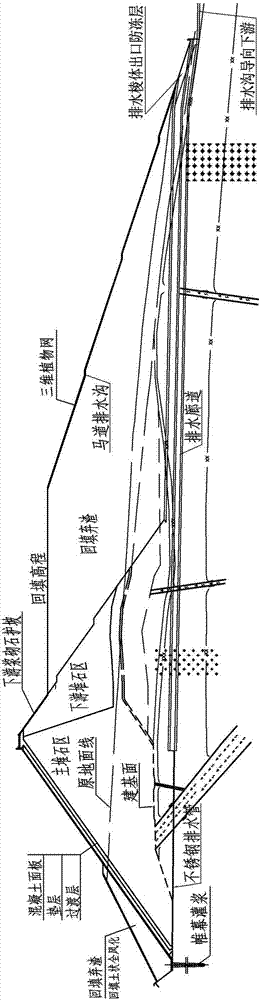

[0015] Below take the large-scale project that has adopted the technical scheme of the present invention as example in conjunction with accompanying drawing to further illustrate: the main dam of the upper reservoir of the Mudanjiang pumped storage power station, the spoil area behind the dam is located within the range line of land expropriation behind the main dam of the upper reservoir, and the main dam On the rear bank slope, within the excavation line of the main dam foundation of the upper reservoir. The main spoil area is located behind the concrete face rockfill dam, where the main dam foundation and revetment excavation, the spoil from the excavation of the stone yard and the excavation spoil of temporary works are mainly stacked, and the spoil volume is about 264×10 4 m 3 , the elevation of the top platform in the spoil area is 640.00m, the top width is 112m, and the downstream side-slope ratio is 1:3.0. Greening and water conservation measures (three-dimensional...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com