Slag stacking structure and slag stacking method

A stone slag and crushed stone technology, applied in the field of hydropower and water conservancy projects, can solve the problems of increasing land acquisition and immigration, environmental protection and long-distance transportation, and achieve the effects of simple protective measures, improved safety performance, and reduced protective capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

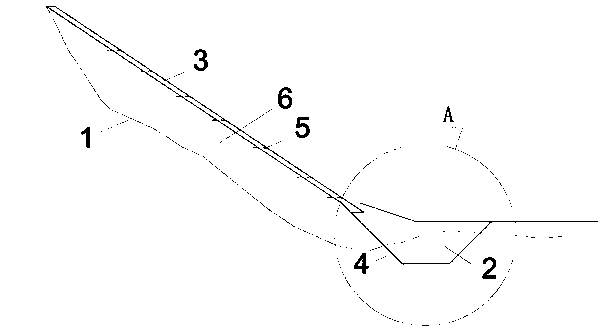

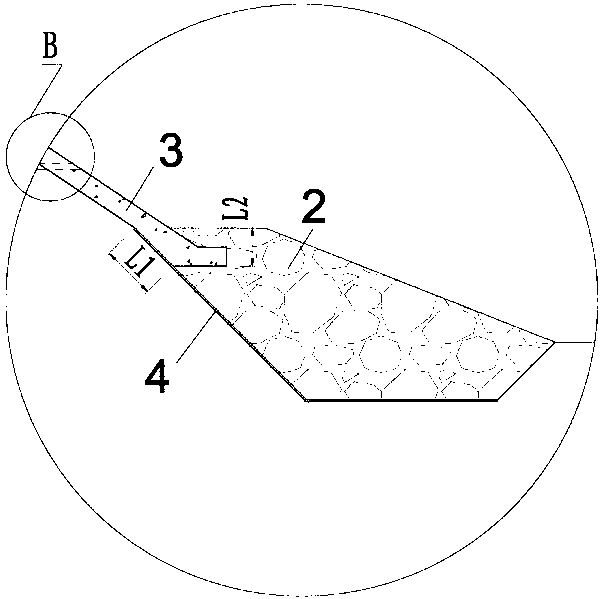

[0022] Such as Figure 1 to Figure 3 As shown, the slag pile structure of the present invention includes a gravel protection foot 2 located below the downstream water level, and a gravel protection slope 6 located above the downstream water level. The gravel protection foot 2 is filled with gravel with a particle size greater than Φ in the gravel Formed, the remaining gravel in the gravel forms a gravel slope protection 6; the surface of the gravel slope protection 6 is covered with a reinforced concrete slab 3.

[0023] The slag pile structure also includes a geotextile 4, and the gravel foot guard 2 is arranged on the geotextile 4.

[0024] There is a blind drainage ditch 5 between the gravel slope protection 6 and the reinforced concrete slab 3 for good drainage.

[0025] The blind drainage ditch 5 extends into the gravel slope protection 6, and the blind drainage ditch 5 is wrapped with geotextile 4.

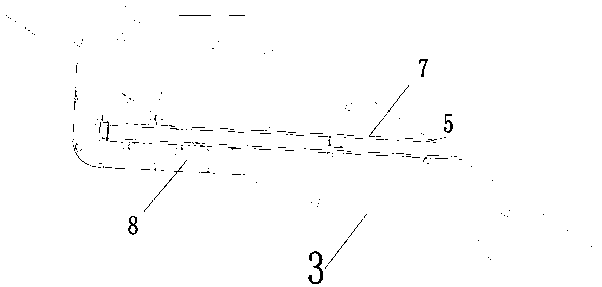

[0026] The slag pile structure also includes a steel wire 7 arranged at the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com