A kind of steel bar connection method of prefabricated concrete member and its application

A connection method and prefabricated parts technology, applied to building components, building structures, walls, etc., can solve the problems of uncontrollable density of grouting materials, increased workload, self-heaviness of laminated floor structures, etc., to achieve modular design , Guarantee the overall performance and the effect of good construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

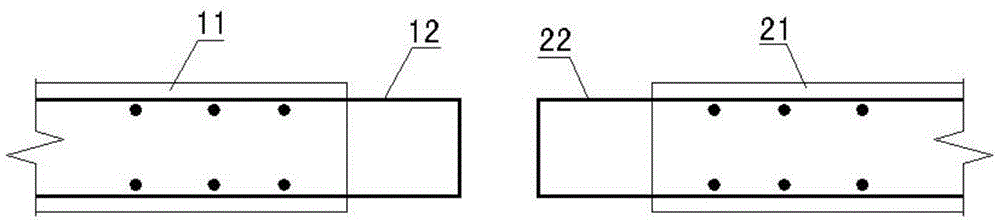

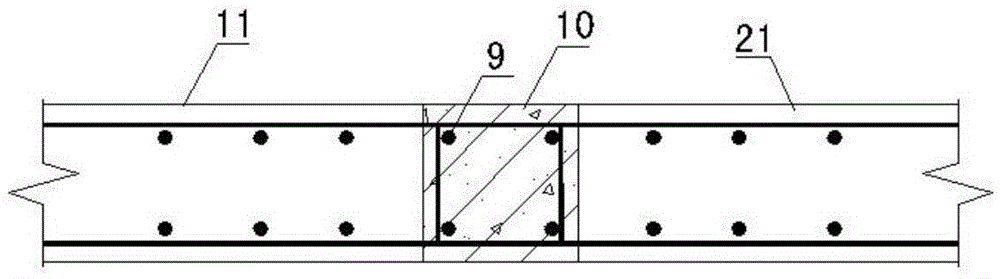

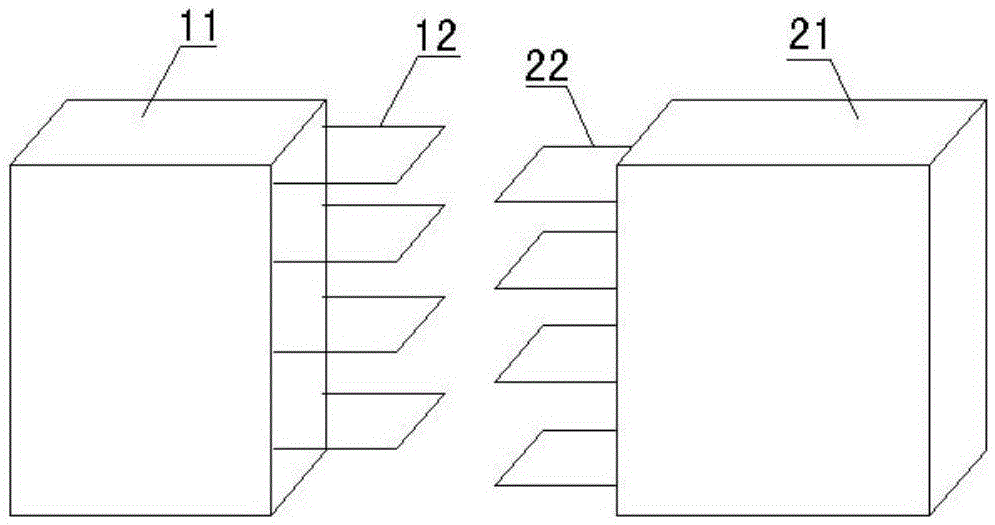

[0053] The steel bar connection mode of the prefabricated concrete member of the present invention is: the connecting bar arranged in the connecting area between two prefabricated parts is a "U" shaped bar bent into a "U" shape by a straight bar, and the "U" At least one end of the rib is pre-embedded in the prefabricated part to form a "U"-shaped connecting rib extending at the end of the prefabricated part. The "U"-shaped connecting ribs extending from the two prefabricated parts are arranged alternately and overlap each other. , forming each rectangular frame at the same longitudinal position, between the rectangular frames and at the four corners of the rectangular frame, connect them in series with vertical straight bars to form a rectangular reinforcement cage.

[0054] In a specific implementation, both ends of the "U"-shaped connecting rib extending at the end of the prefabricated part are pre-embedded in the prefabricated part to form a closed "U"-shaped connecting rib...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap