Trackless mining method for gently inclined vein by adopting rockhole ore removal system as ramp

A mining method and ramp technology, applied in ground mining, mining equipment, earth drilling and mining, etc., can solve the problems of manpower and material resource consumption, long construction period, large mining volume, etc., and achieve reduced labor intensity, low labor intensity, The effect of high production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

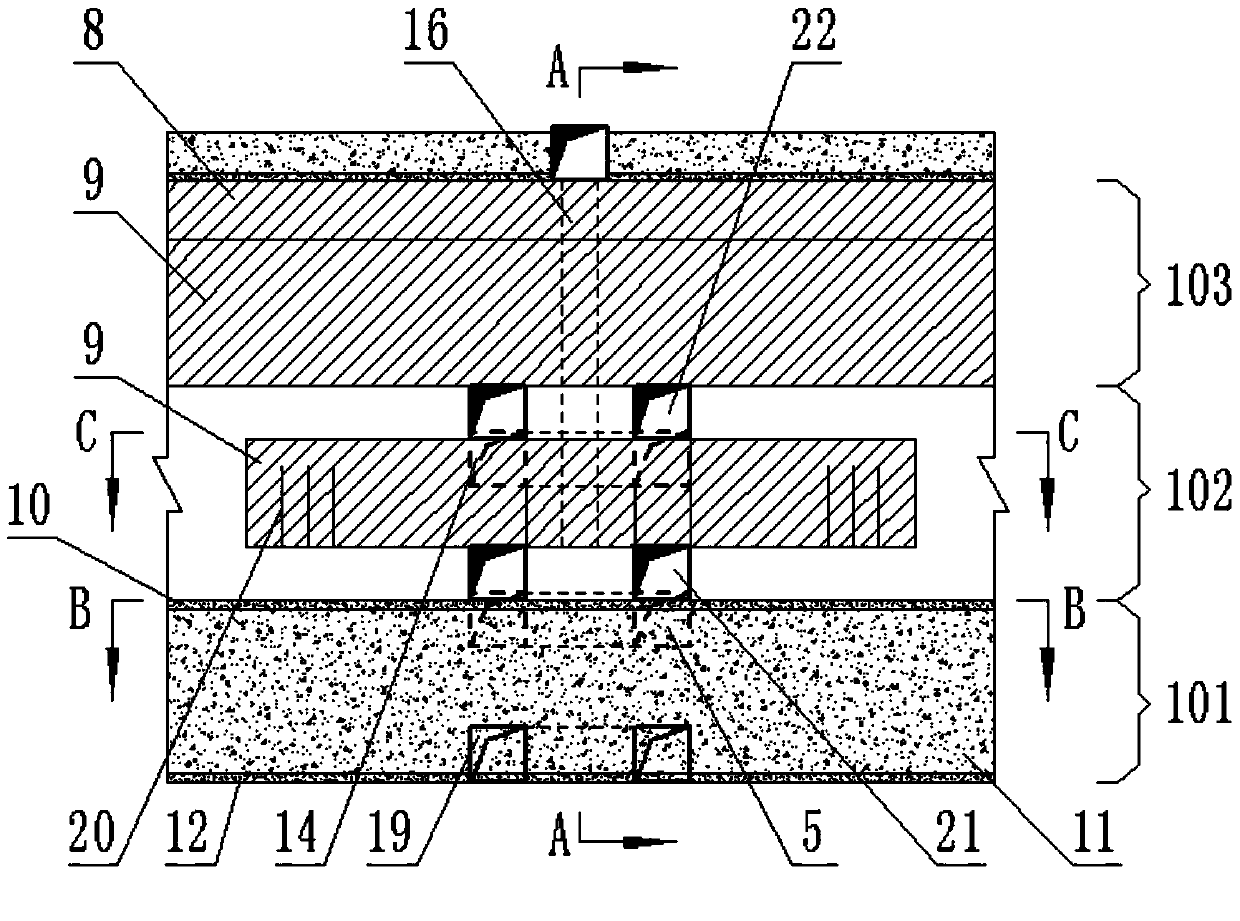

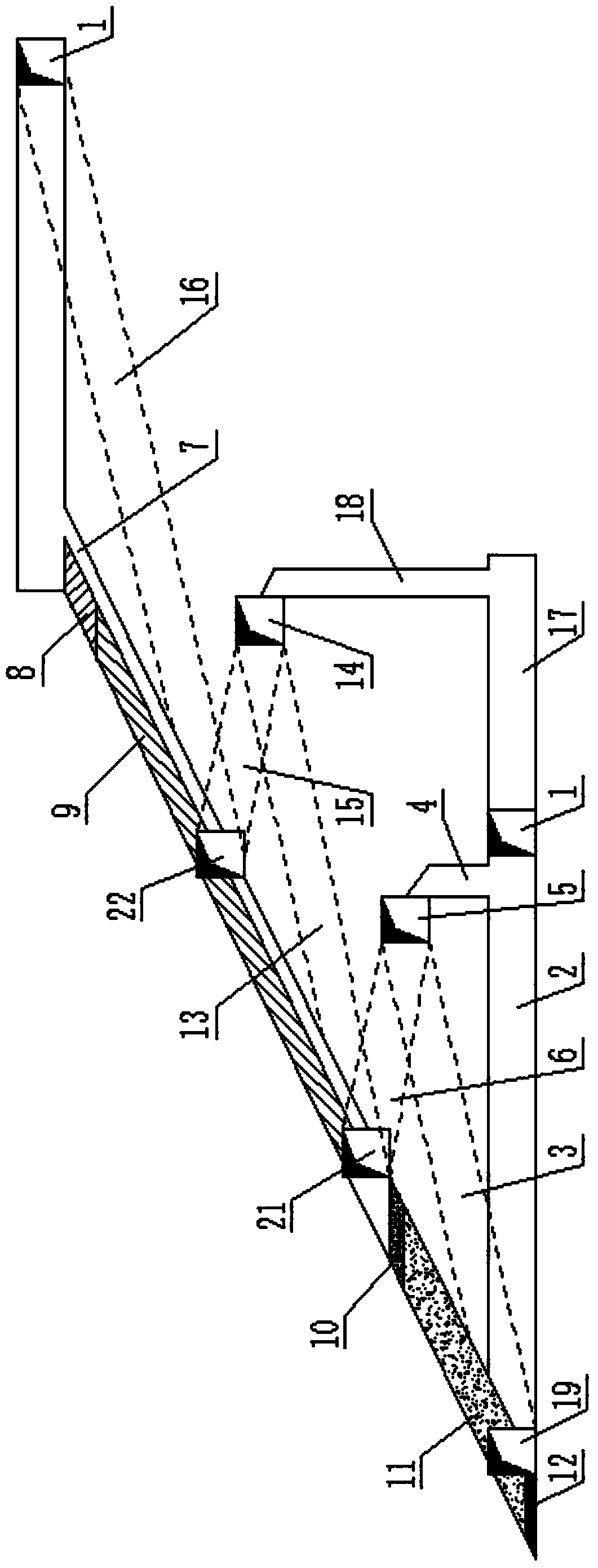

[0044] After the filling of the first section 101 is completed, personnel enter the rock drilling tunnel B21 of the second section 102, and make a layer of cemented surface 10 with a thickness of 0.5 m on the filling body 11; , to carry out the mining operation; the mining method of the second section 102 and the third section 103 is the same as that of the first section 101; B15 goes to the subsection connecting cross alley A5, and the subsection connecting cross alley B14 is transported to the slip mine A4 and the mine slip shaft B18 for ore discharge. All the ore is finally discharged through the stage transport road 1; the filling material is discharged from the filling ventilation shaft 7 in the vein. , mined and filled from bottom to top by subsection. The specific implementation is as follows:

Embodiment

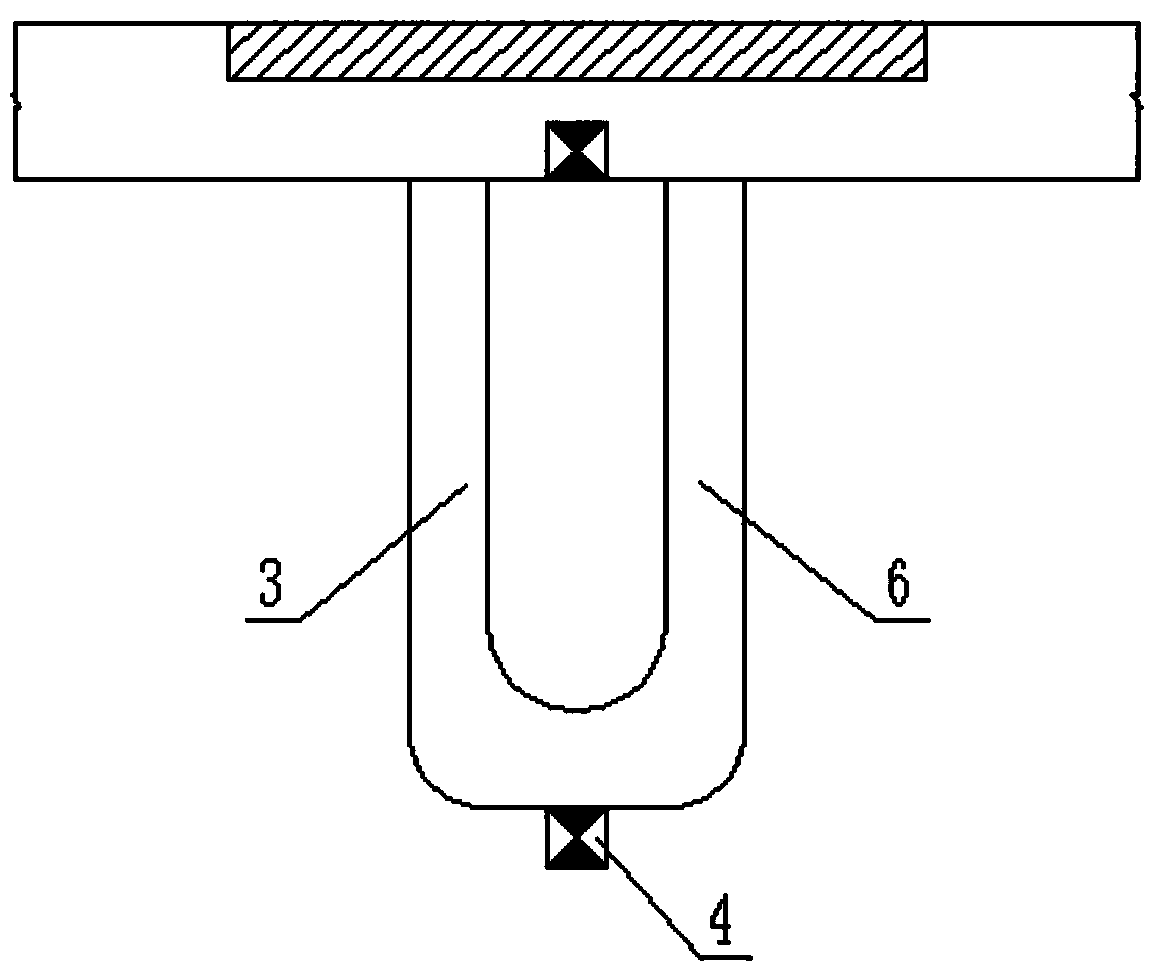

[0045] Example: the ore body 9 is vertically divided into several stages of ore blocks along the direction of figure 1 The first section 101, the second section 102 and the third section 103 are shown in three sections, and the top column 8 is reserved at the top of the third section 103, and the thickness of the top column 8 is 2.5m; Figure 2-4 As shown, in the middle position of the stage ore block on the side of the lower wall and parallel to the ore body 9, an in-vein filling ventilation shaft 7 is opened. The cross-section of the in-vein filling ventilation shaft 7 is a rectangle of 1.5m×2m. From left to right 2 / 3 of the end, excavate a stage transport roadway 1 parallel to the stage ore blocks; from the middle position of the stage transport roadway 1 corresponding to the stage ore blocks direction to the direction away from the stage ore blocks, excavate a horizontally arranged concentrated mine Level road 17,; from the stage transport road 1 to the position 4.5m away ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com