A Partition Upward Layered Filling Mining Method for Medium Thick and Steeply Inclined Extremely Broken Orebody

A backfill mining method and steep incline technology, which is applied in the fields of backfill, ground mining, mining equipment, etc., can solve the problems of poor ventilation conditions, complex mining process in the approach method, and large workload of development and mining, so as to reduce the loss rate. and dilution rate, improve stope production capacity, and improve the effect of mining economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with accompanying drawing.

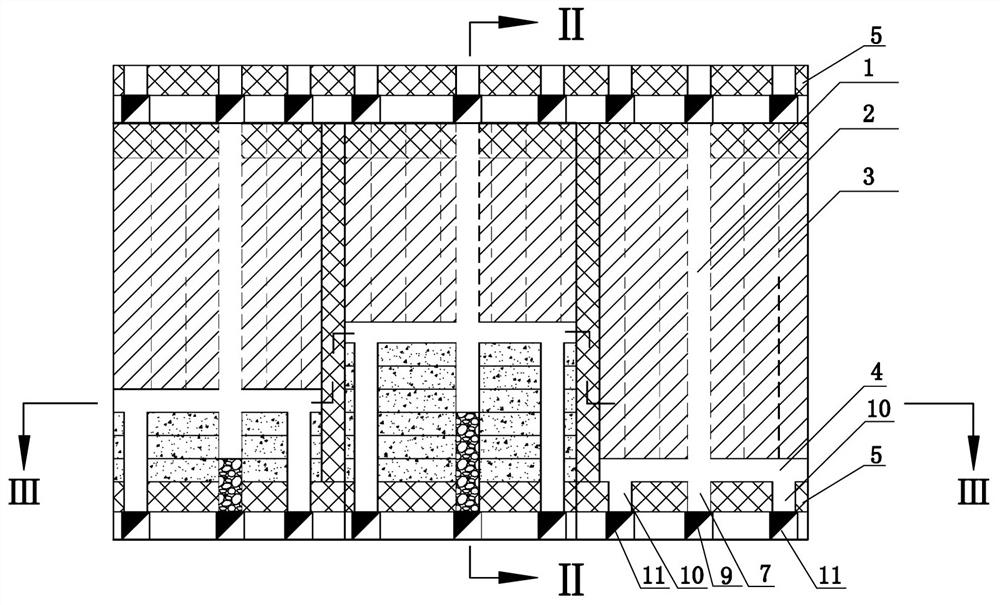

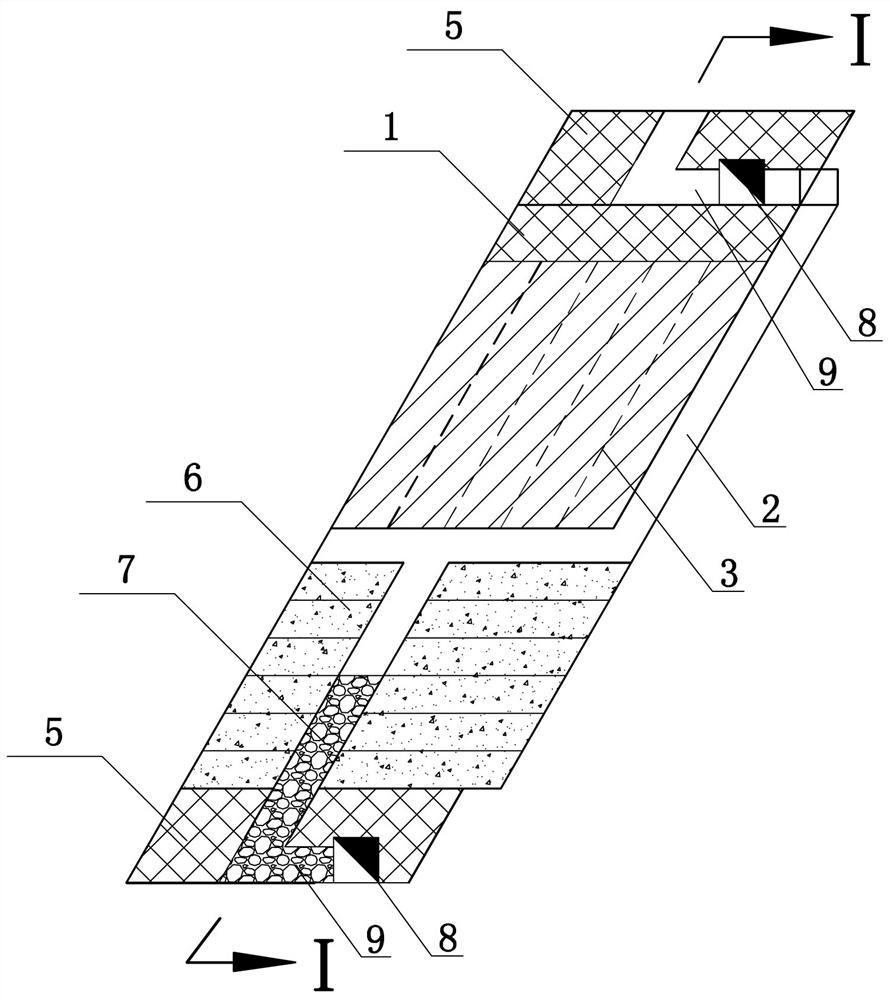

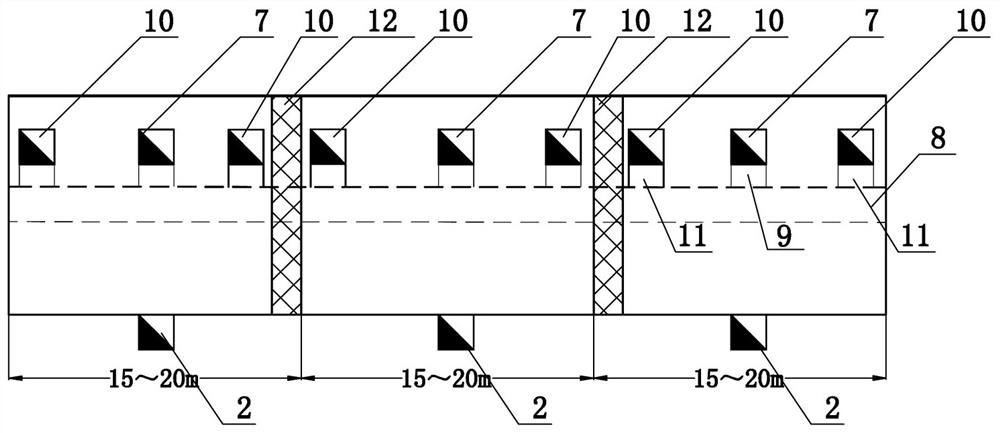

[0038] The present invention provides a mining method for layered upward filling of medium-thick steeply inclined extremely broken ore bodies. Within the range of ~60m, the stope is divided into 10~15 sections in the stage, and the section height is 3m~5m. In the stage, multiple stopes are divided along the ore body trend, and the stope is divided into multiple partitions, 3~ Five partitions constitute a stope, and isolated mine walls are reserved between the partitions; the length of the stope is within 45m to 100m, and the length of each partition is within 15m to 20m; the specific steps are as follows:

[0039] Approved project:

[0040] In each subdivision unit, carry out in-vein mining, and in each subdivision unit, arrange the stage transportation level roadway 8, the stage ore exit horizontal roadway 9, the pedestrian inlet air patio 10, the pedestrian inlet wind pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com