A valve core and a quick exhaust valve using the valve core and a pneumatic piston actuator

A technology of exhaust valve and spool, applied in the direction of valve shell structure, engine components, valve operation/release device, etc., can solve the problem of easy skew of the valve core, so as to avoid the skew of the valve core, reduce the contact surface, and reduce the friction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

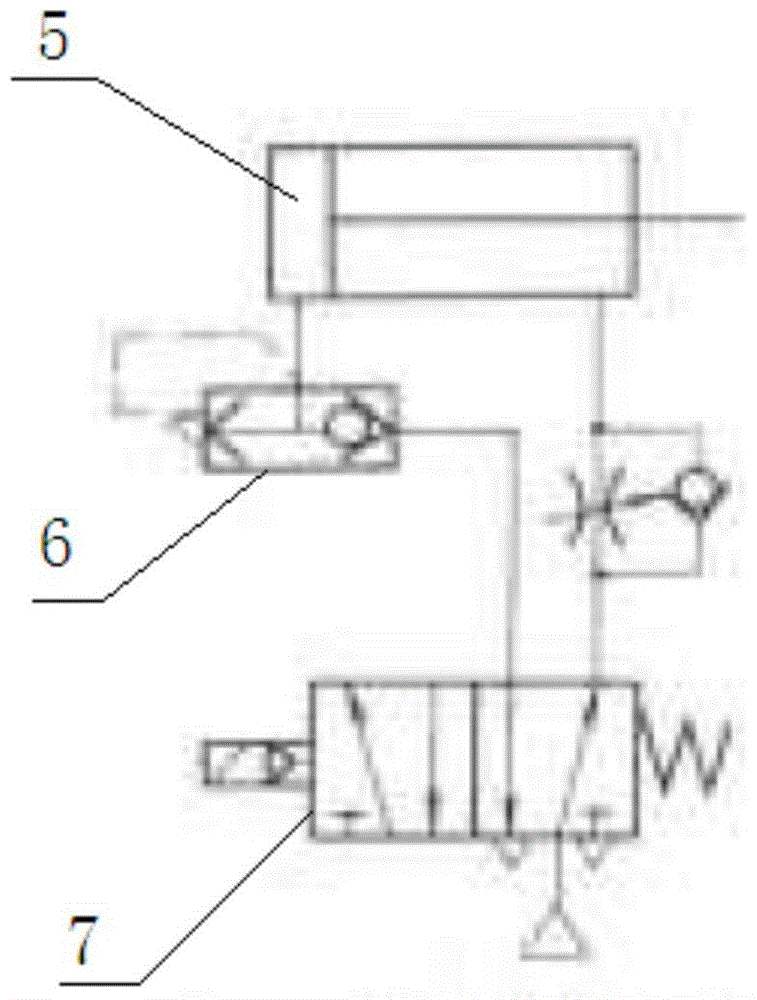

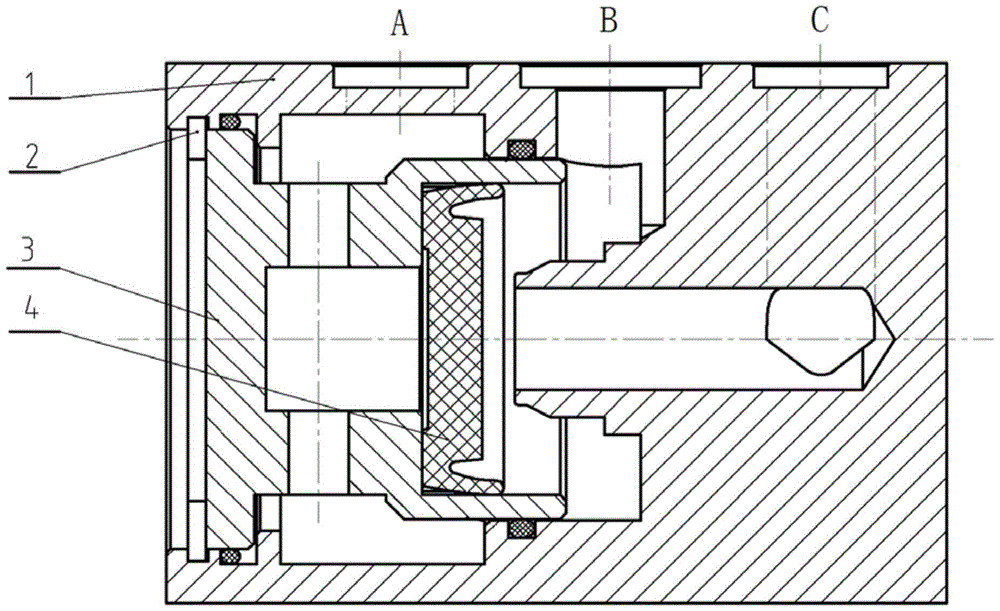

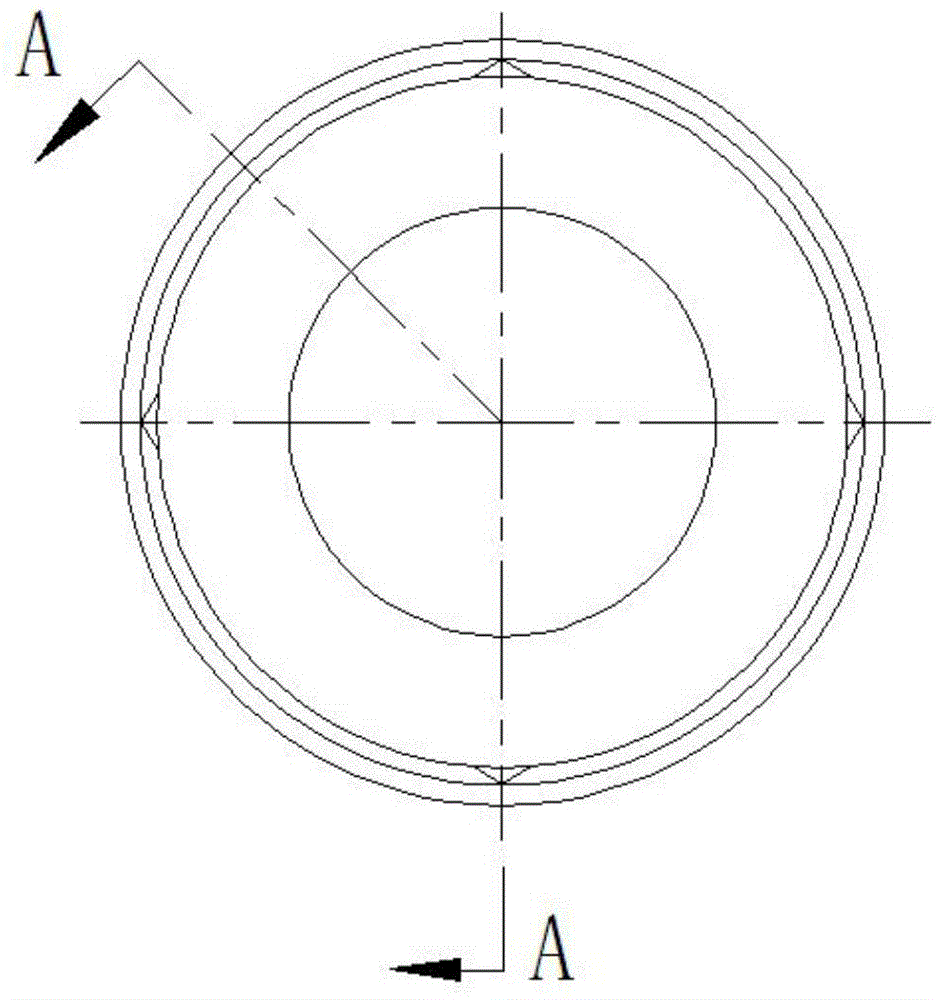

[0026] Such as Figure 2-6 The quick exhaust valve shown includes a valve body and a valve cavity, and a valve core 4 that moves left and right is installed in the valve cavity. The above-mentioned valve body includes a valve seat 1 and a valve core seat 3. The valve seat 1 is provided with a first passage A, a second passage B and a third passage C which are all communicated with the valve cavity. The right end of the above-mentioned valve core seat extends into The valve seat 1 is inserted into the support hole of the valve seat. In order to prevent gas leakage between the first channel A and the second channel B, a sealing ring is added at the support hole. The left end of the valve core seat is inserted into the installation hole on the left end face of the valve seat, and is detachably installed through the annular protrusion on the right side of the installation hole on the valve seat and the retaining ring 2 stuck on the left side of the installation hole. On the valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com