Connector hard sealing structure for corrugated stainless steel hose

A corrugated hose and hard seal technology, which is applied in the direction of hose connection devices, pipes/pipe joints/fittings, sealing surface connections, etc., can solve the problems of poor sealing performance, large quality differences, and limited service life and other problems, to achieve the effect of small joint size, high-quality sealing performance, and fast installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing of description, the present invention will be further described.

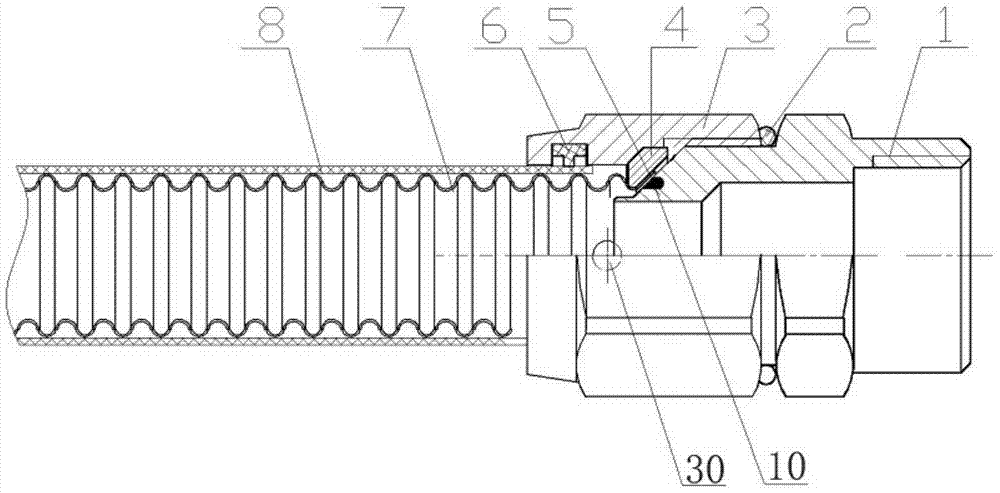

[0024] Such as figure 1 As shown, a stainless steel corrugated hose joint hard seal structure includes a corrugated hose 7, a nut 3 and an outer wire joint 1; The nuts 3 are connected; a split snap ring 4 that can stop the nut 3 from coming out is also included. The ring cavity is a two-half ring structure of a cone, the bottom of the outer ring surface of the snap ring 4 is set as an outer cone ring surface structure, and the outer cone ring surface of the snap ring 4 is in contact with the inner cone ring surface of the nut 3 Cooperate. The first wave of the corrugated hose 7 is in the corrugated ring at the mouth of the ring cavity of the snap ring 4, which is formed into a tapered ring clamped on the tapered surface of the ring cavity of the snap ring 4 by beating waves; the screwed corrugated hose 7 The end of the outer wire connector 1 is inlaid wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com