Measuring and Adjusting Method of Station Axis Center Accuracy of Disc Multi-station Machine Tool

A technology of precision measurement and adjustment method, which is applied in the direction of mechanical measuring devices, measuring devices, mechanical devices, etc., can solve the problems of inapplicability, mutual influence of detection and adjustment, etc., and achieve the effect of improving machining accuracy and reducing eccentricity error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

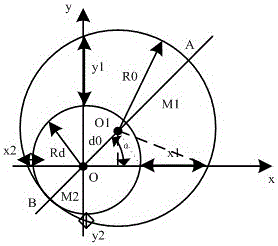

[0032] see Figure 1-5 , the station axis accuracy measurement and adjustment method of the disc type multi-station machine tool of the present invention is composed of a single-station measurement mechanism and a data processing and adjustment method.

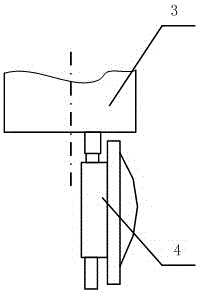

[0033] figure 1 It is a schematic diagram of a single-station detection mechanism. figure 1 Among them, detect the mandrel 3 and the lever dial indicator 4. When testing, remove the power head, and replace the power head with the detection mandrel 3. There are threads at the protrusions at the top of the detection mandrel 3 , and the lever dial indicator 4 is fixed on the detection mandrel 3 through threaded connections during detection.

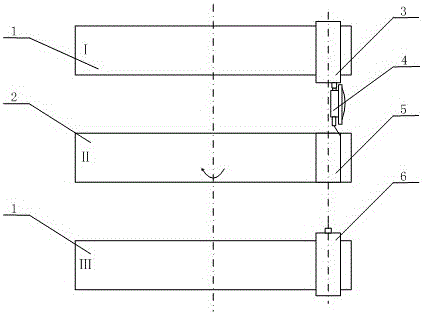

[0034] figure 2 Is the measurement schematic diagram of the invention of the method. figure 2 Among them, 1 is the power plate for placing the motor and tool,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com