Evaluation method for the gap between linear roller joints of automobile seat guide rails

A roller joint, car seat technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve difficult problems, can not solve the abnormal noise of car seat rails, and can not provide reasonable assembly preload Guiding value and other issues to achieve the effect of reducing the generation of gaps and solving vibration and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

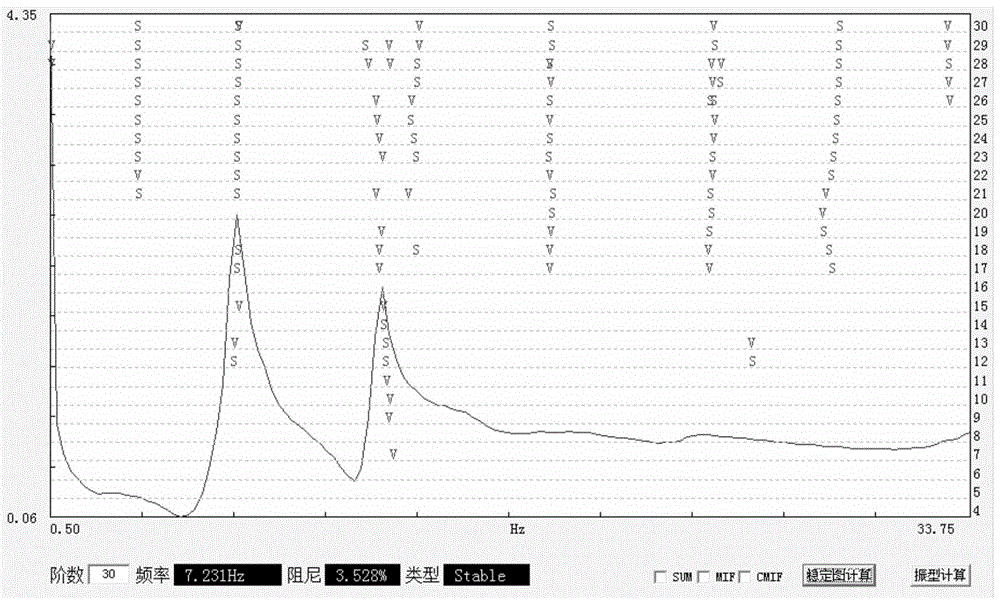

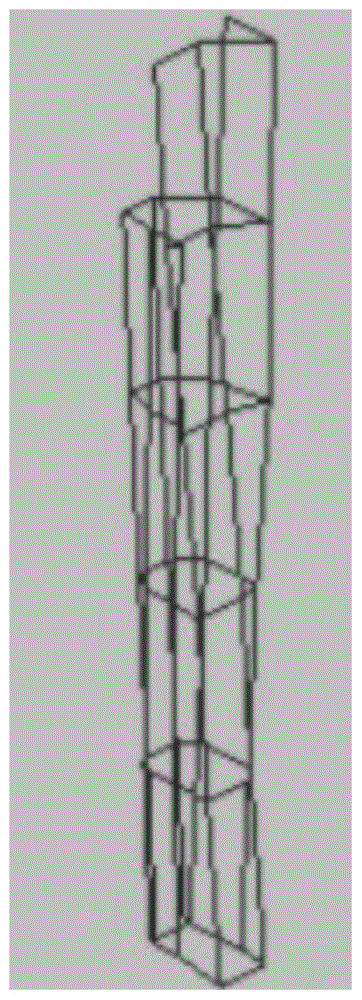

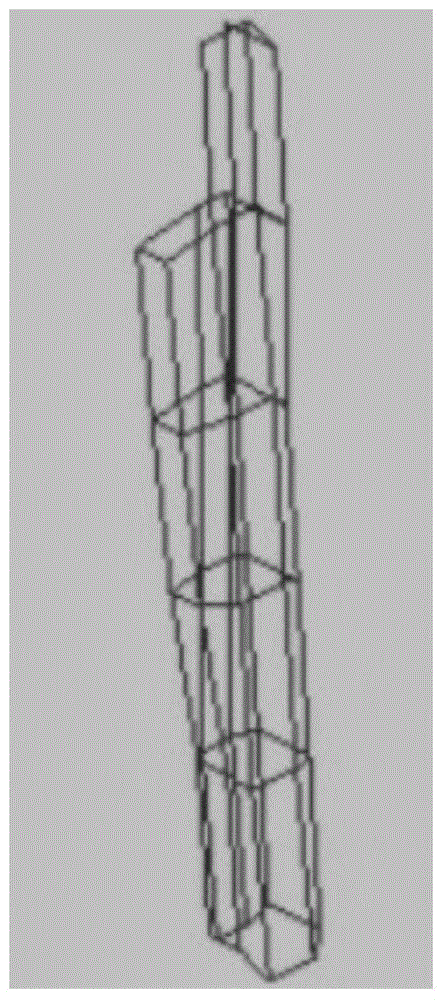

[0037] The evaluation method of the present invention is realized based on finite element dynamics simulation. In the present invention, the premise of the evaluation method for the clearance of the linear roller joint of the automobile seat guide rail is to establish a finite element model of the automobile seat guide rail. In this finite element model, the spring-damper element is used to characterize the contact relationship between the steel ball and the inner and outer rails. In this way, the characteristics of the steel ball and the inner wall of the guide rail that are sometimes compressed and sometimes separated under the random road surface excitation will be represented by the relative displacement between the two ends of the spring damping unit. Through the statistical analysis of the relative displacement between the two ends of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com