High Power Switch with Current Limiter

A high-power switch and current limiter technology, applied in high-voltage/high-current switches, electrical switches, high-voltage air circuit breakers, etc., can solve high technical risks and development costs, fail to achieve technical and economic effects, and break short-circuit current. Failure and other problems, to achieve the effect of shortening the arcing time, improving economic benefits, and improving the success rate of breaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

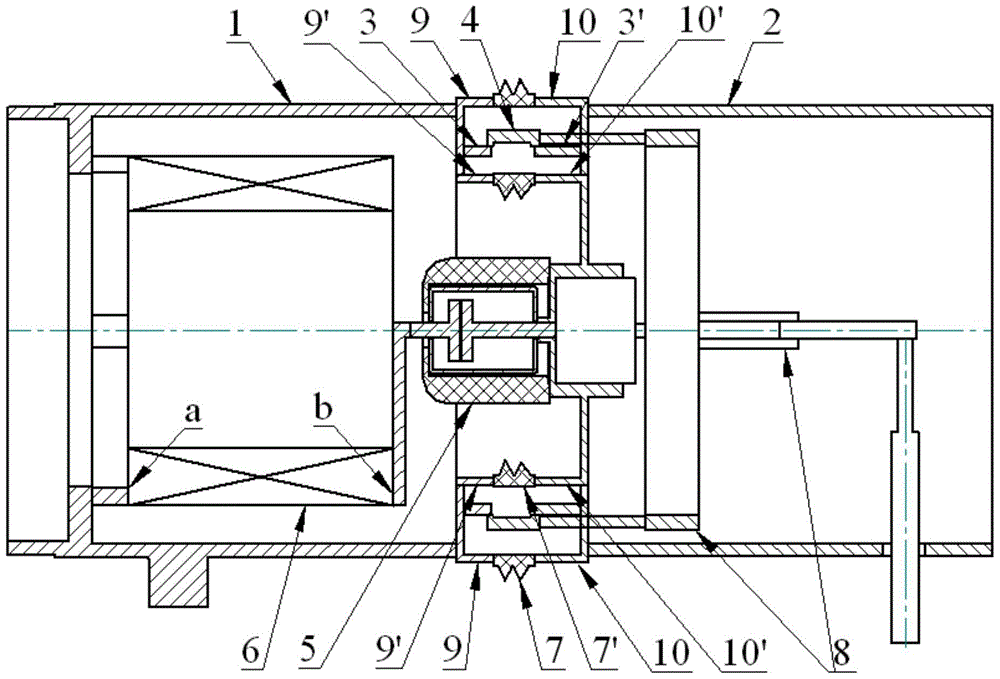

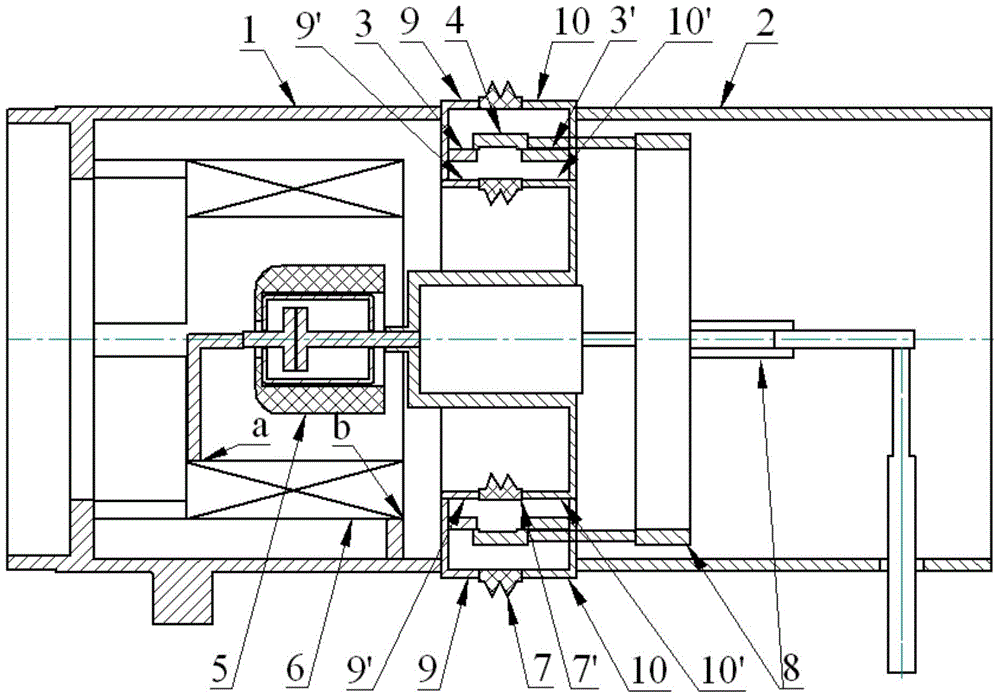

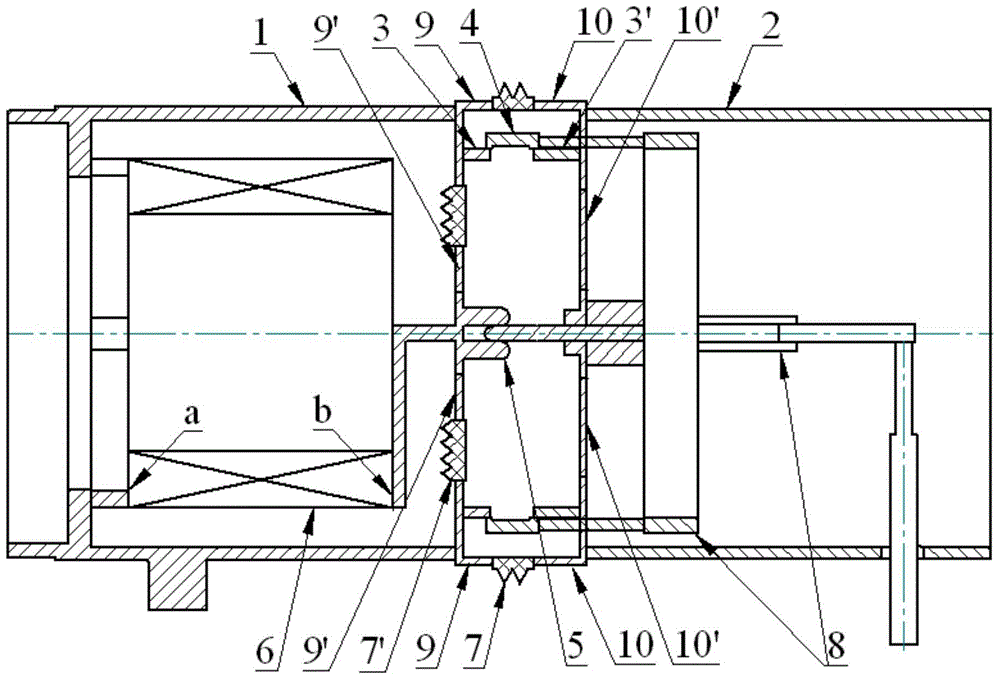

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings:

[0026] See figure 1 , figure 2 with image 3 . The high-power switch with current limiter according to the present invention includes the first and second main conductors 1, 2, the first and second static main contacts 3, 3', and the moving Main contact 4, first and second outer connecting bodies 9, 10, first and second inner connecting bodies 9', 10', breaking device 5 with arc extinguishing function, current limiter 6, first and second Two insulators 7, 7'and an operating mechanism 8.

[0027] The first main conductor 1 and the second main conductor 2 are coaxially arranged. The first main conductor 1, the first outer connecting body 9, the first static main contact 3, the moving main contact 4, the second static main contact 3', the second outer connecting body 10 and the second main conductor 2 are connected in sequence A main conductive loop is formed, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com