Anti-sand pressure relief ring network cabinet

A pressure relief ring and network cabinet technology, applied in the field of ring network cabinets, can solve problems such as pressure relief hole blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

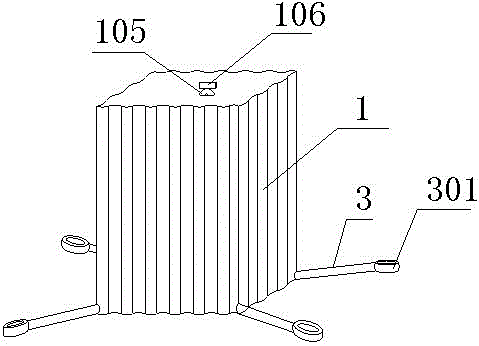

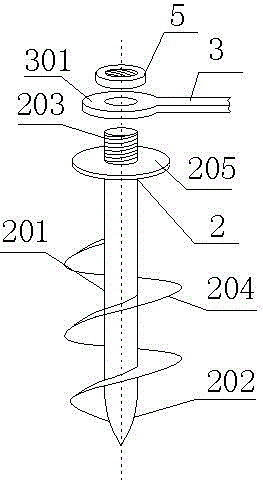

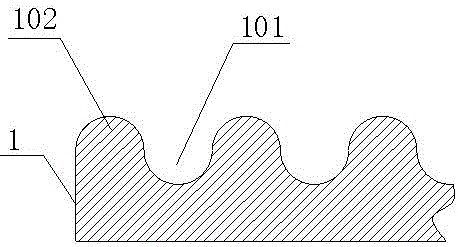

[0022] like Figure 1-6 As shown, the sand prevention and pressure relief ring network cabinet includes a cabinet body 1 and four installation rods 2. A connecting rod 3 is respectively arranged on the four corners of the lower end of the cabinet body 1, and one end of the connecting rod 3 is movably connected to the cabinet body 1. , the other end is provided with a collar 301, the installation rod 2 includes a straight rod 201, one end of the straight rod 201 is a tip 202, and the other end is a threaded end 203, and the straight rod 201 is provided with a helical leaf 204 around the tip 202, And near the threaded end 203, a stop ring 205 is provided, the inner diameter of the collar 301 matches the diameter of the straight rod 201, the side of the cabinet body 1 is arranged with semicircular grooves 101 arranged at intervals, between adjacent semicircular grooves 101 Be provided with semicircle protruding line 102, described semicircle groove 101 is parallel with semicircle...

Embodiment 2

[0025] like Figure 7 , Figure 8 , the structure of this embodiment is basically the same as that of Embodiment 1, the difference is that a hoop 4 is arranged directly above the connection between the connecting rod 3 and the cabinet body 1, the inner diameter of the hoop 4 is matched with the connecting rod 3, and the hoop 4 includes Two half-rings 401 , one of which is fixed on the cabinet body 1 . The hoop is used to fix the connecting rod, mainly because when the ring network cabinet is moving, the connecting rod 3 will swing, which is very obstructive and not conducive to the handling of the device, so it is convenient to set the hoop 4 to fix the connecting rod 3 transport. Both ends of the half-ring 401 are provided with connectors 402 , and the connectors 402 are provided with threaded holes 403 , and the two half-rings 401 are fixed through the connectors 402 . The distance from the hoop 4 to the joint between the connecting rod 3 and the cabinet body 1 is less th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com