Device for manufacturing electrode for power-adjustable electric heating tube

An electric heating tube and adjustable technology, applied in ohmic resistance electrodes, ohmic resistance heating parts and other directions, can solve problems such as affecting production and operation costs, weakening the core competitiveness of the product market, and low degree of automation, so as to improve detection and electrode Preparation accuracy, improving quality and production efficiency, and the effect of small width variation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

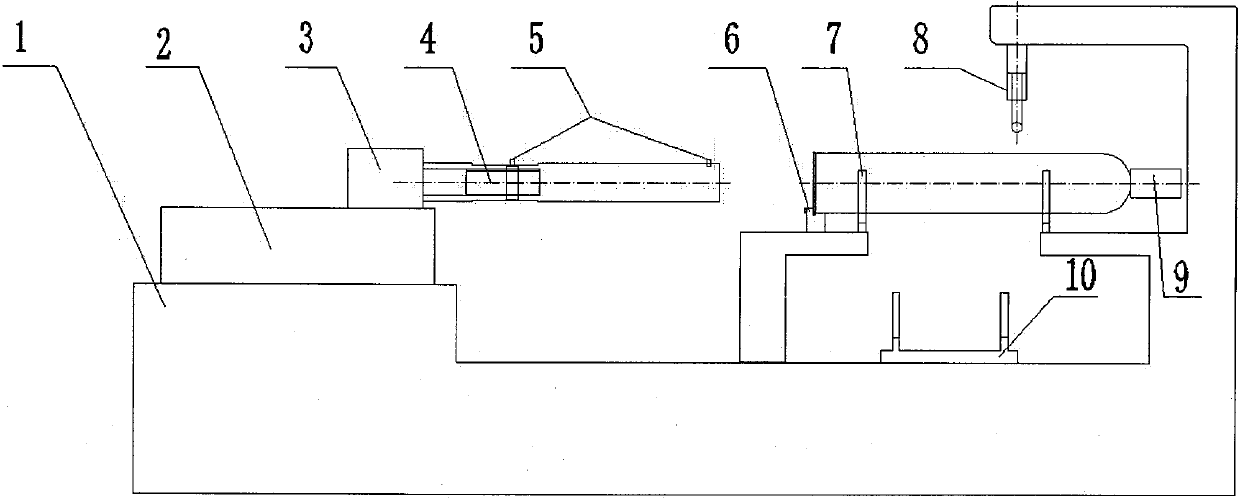

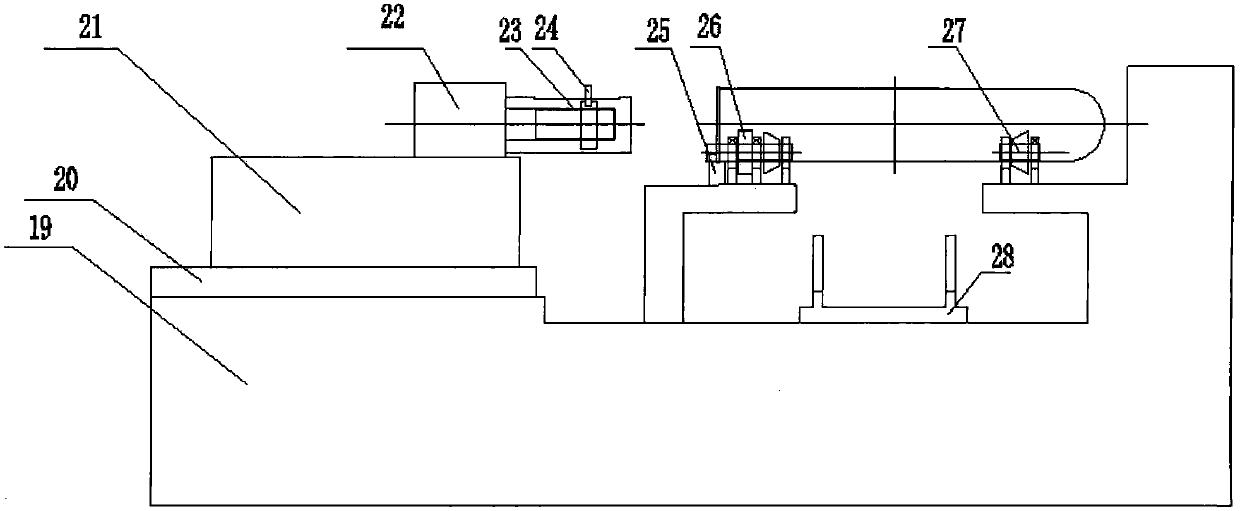

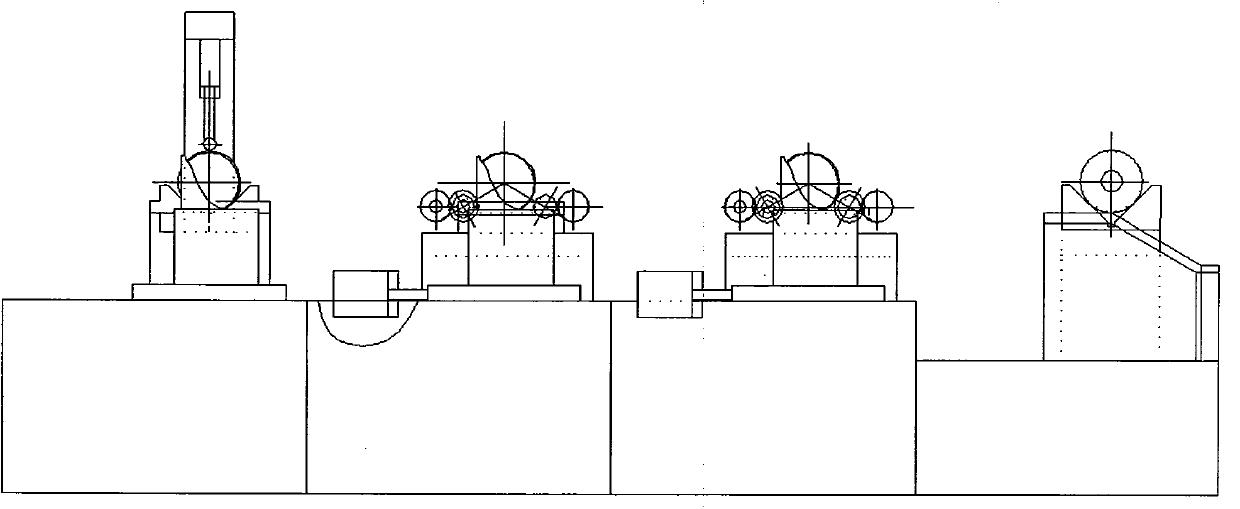

[0016] figure 2 shown. When the heating tube reaches the V-shaped block 7, the electromagnet 9 loses power and compresses the heating tube, and the cylinder 8 moves downward under the action of the controller to compress the tube. The slider drive mechanism 2 moves to the inside of the pipe under the control, and stops moving after reaching the set value. The controller drives the three-point probe to expand to contact the inner wall of the pipe. If the measured value is not within the set range, the controller calculates Determine the difference between the resistance values, and then the outer probe shrinks, the control device controls the movement of the servo motor 3 to make it reach the set value, and finally the outer probe expands to contact the inner tube wall. If the set value cannot be satisfied within the movable range of the servo motor 3, the tube is a waste product. The data of the movement of the servo motor 3 is recorded in the control device. After the mea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com