Preparation method for effectively improving famous sun-cured tobaccos

A modulation method, known as sun-cured tobacco technology, applied in tobacco, tobacco preparation, tobacco treatment, etc., can solve the problems of high humidity on the ground, dark color of tobacco leaves, poor ventilation, etc., and achieve rapid drying, consistent color shades, and easy manipulation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

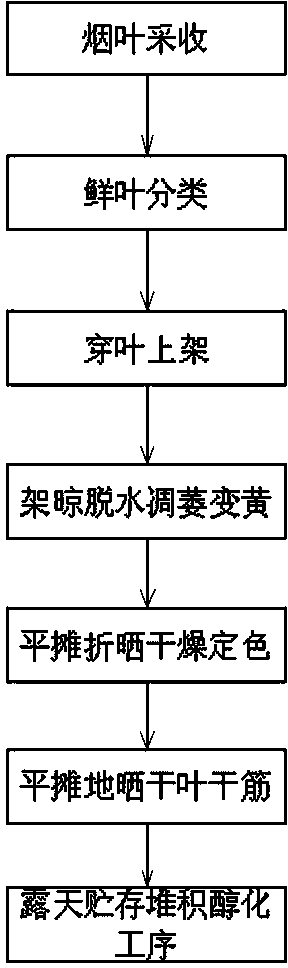

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with examples, but the present invention is not limited in any way, and any transformation or improvement made based on the teaching of the present invention all falls within the protection scope of the present invention.

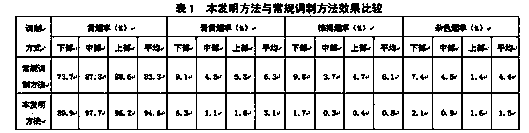

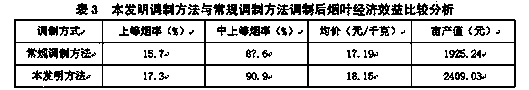

[0019] The method of the present invention controls the temperature and humidity in the drying shed by uncovering the plastic film on both sides of the drying shed, sprinkling water on the ground to increase humidity, covering the sunshade net, and adjusting the distance of the tobacco ropes, etc. Sufficient, or excessive humidity, excessive yellowing of tobacco leaves and other phenomena occur. Add a drying process before ground drying to reduce the phenomenon of dark color, dark luster, and many variegated colors caused by direct contact with the ground when the tobacco leaves have a large water content and poor ventilation and moisture drainage, so that the tobacco leaves can be d...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap