An assembly and positioning mechanism of a vacuum cleaner for a bed

A positioning mechanism and technology for vacuum cleaners, applied in vacuum cleaners, applications, electromechanical devices, etc., can solve problems such as inaccurate installation and positioning of vacuum cleaners, installation errors, increased production and maintenance costs, etc., to improve positioning accuracy and installation efficiency, and improve service life , the effect of good user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The commonly used bed vacuum cleaners are generally hand-held vacuum cleaners. The driving motor generally has high noise during operation, and the vibration of the handshake is relatively large, which seriously affects the normal use of users. The environmental quality during cleaning is poor, reducing the quality of products use value. Moreover, each part of the bed vacuum cleaner is mainly installed and fixed manually after the processing is completed, and the installation and positioning are not accurate, which affects the quality and normal use of the vacuum cleaner, and the installation efficiency is low.

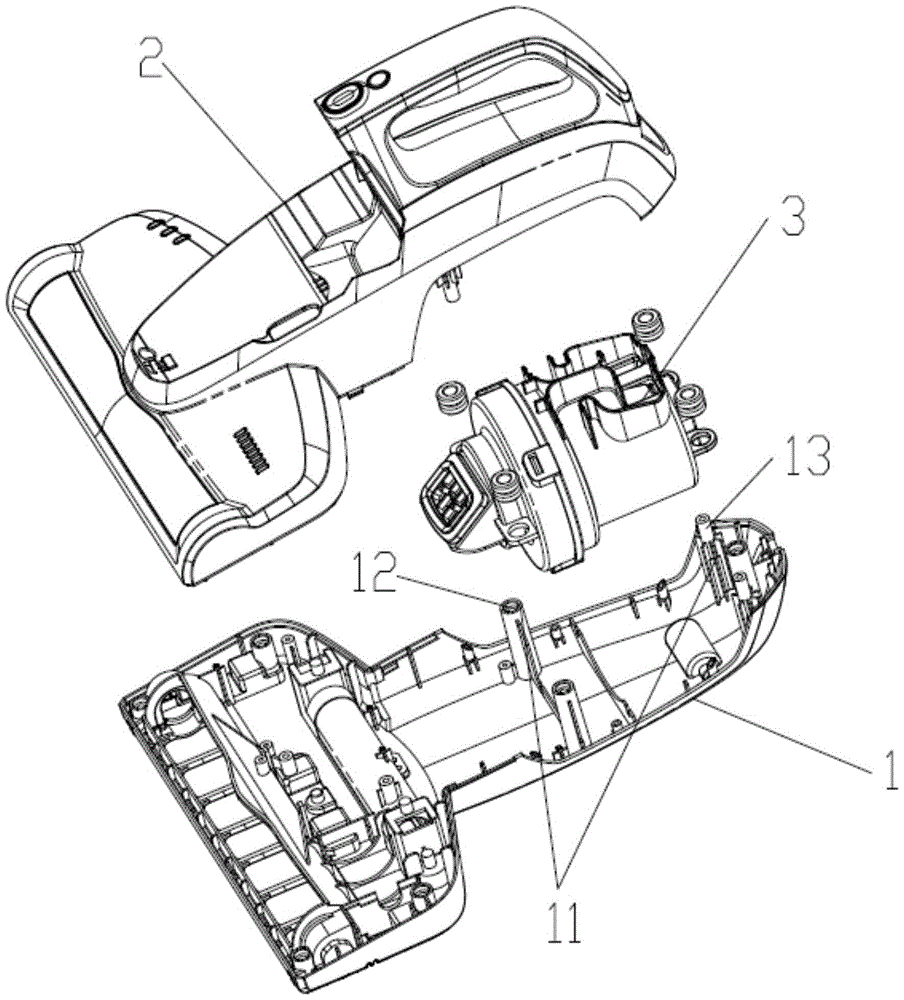

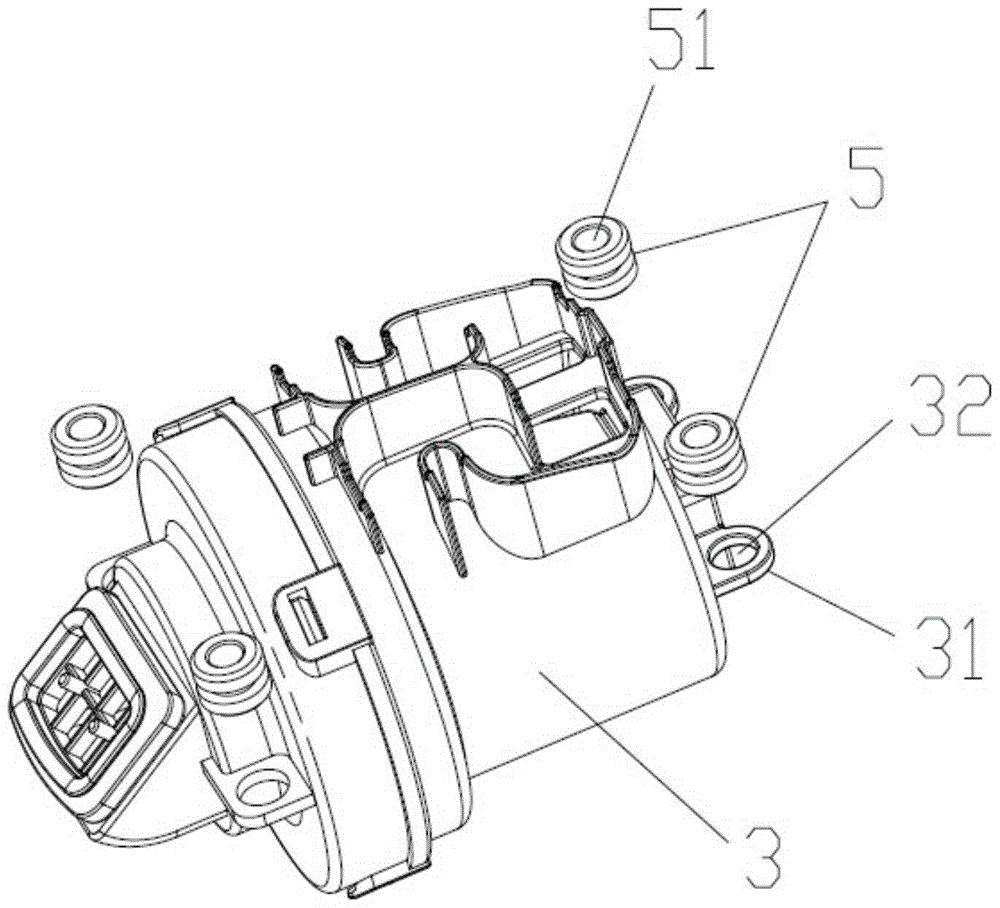

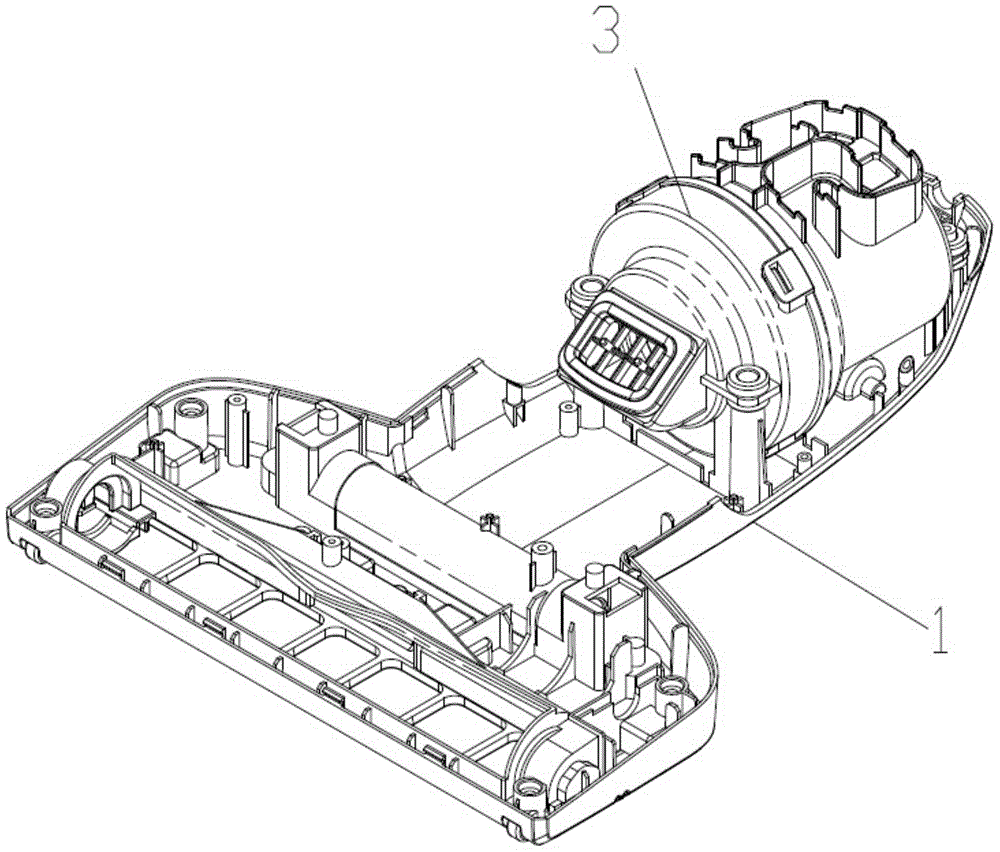

[0032] Aiming at the deficiencies in the prior art, the present invention provides an assembly and positioning mechanism for bed vacuum cleaners. A soft connection is formed by arranging shock-absorbing components at the joints of the motor cover, the base and the upper cover to support the motor cover, so that the motor cover is suspended state, reduce the vib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com