Dust collection unit of cloth bag type dust collector

A bag filter and bag room technology, applied in chemical instruments and methods, separation of dispersed particles, filtration of dispersed particles, etc., can solve the problems of affecting the dust removal effect of the dust collector, failing to achieve the dust removal effect, high maintenance cost, etc., and achieve the dust removal effect Good, simple structure, uniform cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

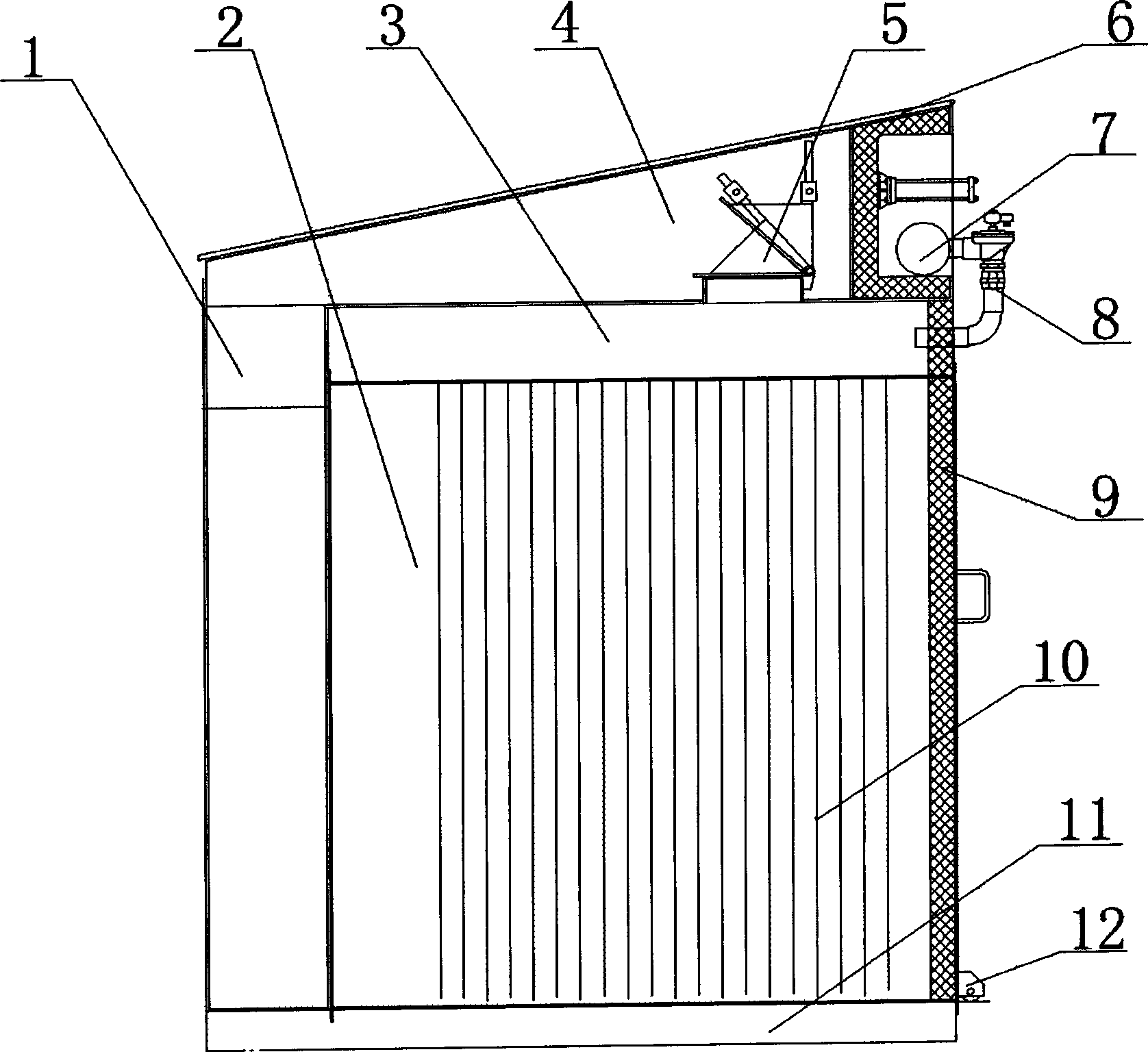

[0016] like figure 1 As shown, a dust removal unit of a bag filter includes a steel body 11, a clean air collection flue 1 and a pulse gas distribution bag 7, and a drawer-type bag room 2 is provided inside the steel body 11, and the drawer-type bag room 2 The upper part is provided with a clean air chamber, and the top of the clean air chamber is provided with an ash dropping device 6, and the bottom of the drawer-type bag chamber 2 is provided with guide wheels 12. The clean air chamber is divided into a lower clean air chamber 3 and an upper clean air chamber 4 , and the ash falling device 6 is arranged on the top of the upper clean air chamber 4 . An offline valve 5 is arranged inside the upper clean air chamber 4 . The pulse gas distribution bag 7 is connected with a pulse valve 8 . A filter bag 10 is arranged inside the drawe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com