Composite material capable of separating mixed xylene and preparation method of composite material capable of separating mixed xylene

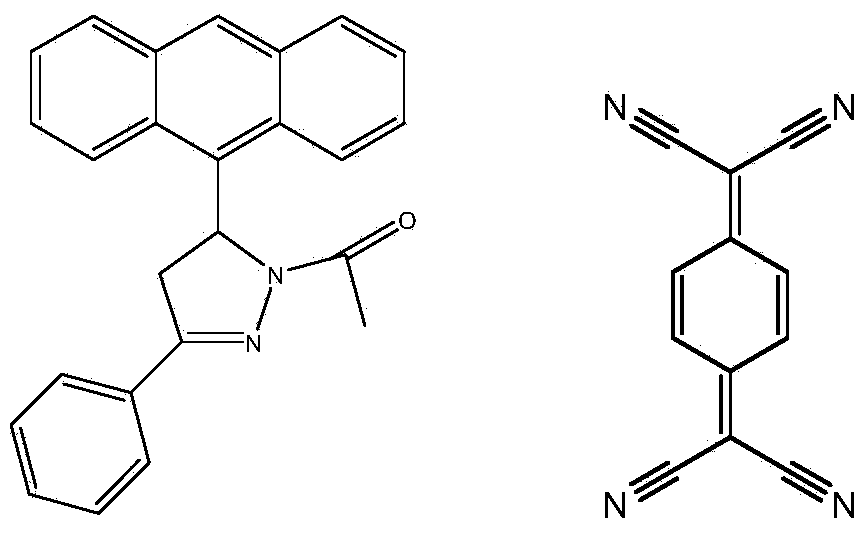

A composite material, mixed xylene technology, applied in adsorption purification/separation, chemical instruments and methods, other chemical processes, etc., can solve problems such as inability to separate mixed xylene, and achieve the effect of enhanced supramolecular interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

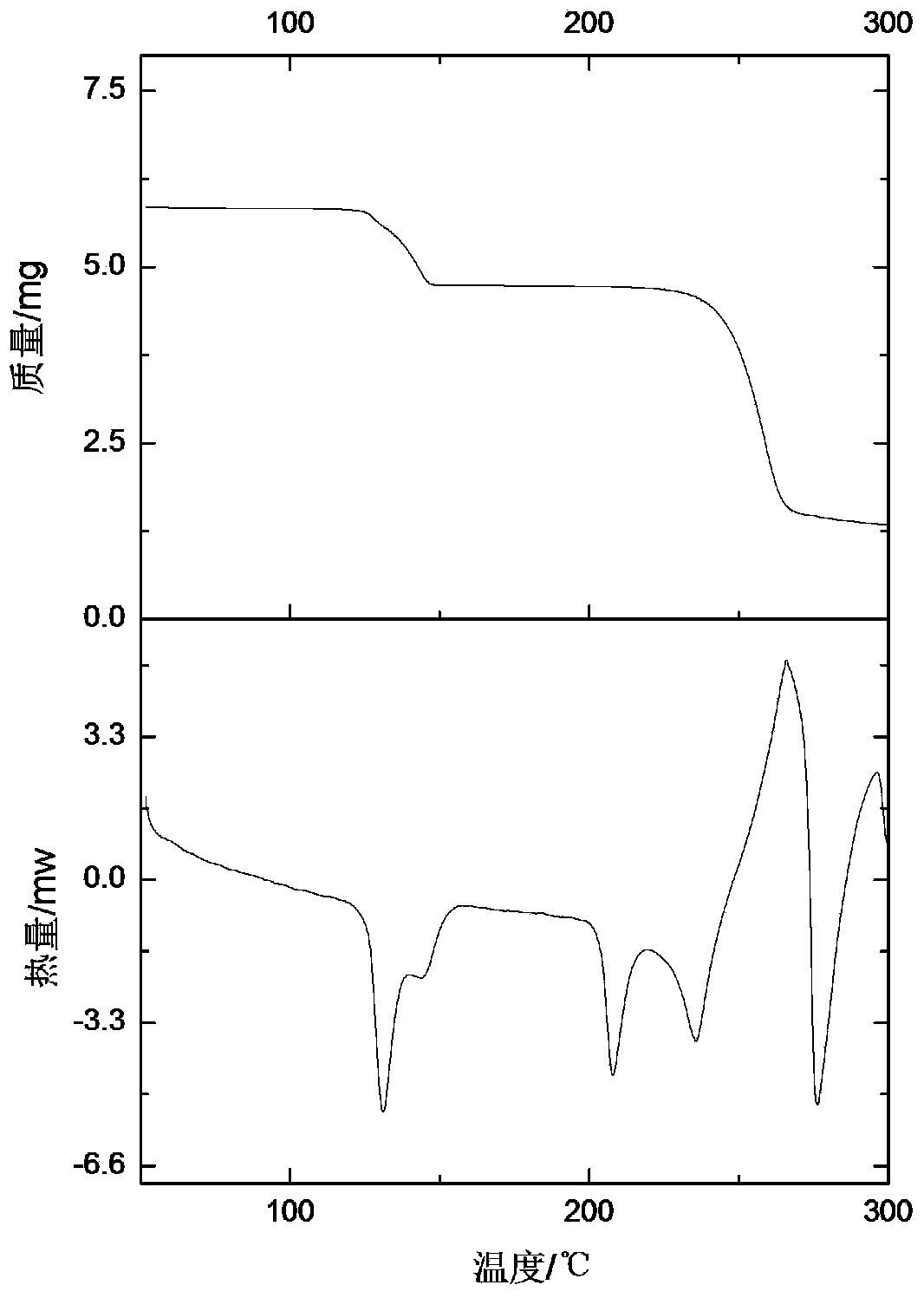

Embodiment 1

[0025] After 72.80g of APPP and 40.8g of TCNQ were dissolved in toluene solvent, after standing still for 24 hours, the solvent was removed under vacuum and decompression, and the porous composite material was obtained by drying.

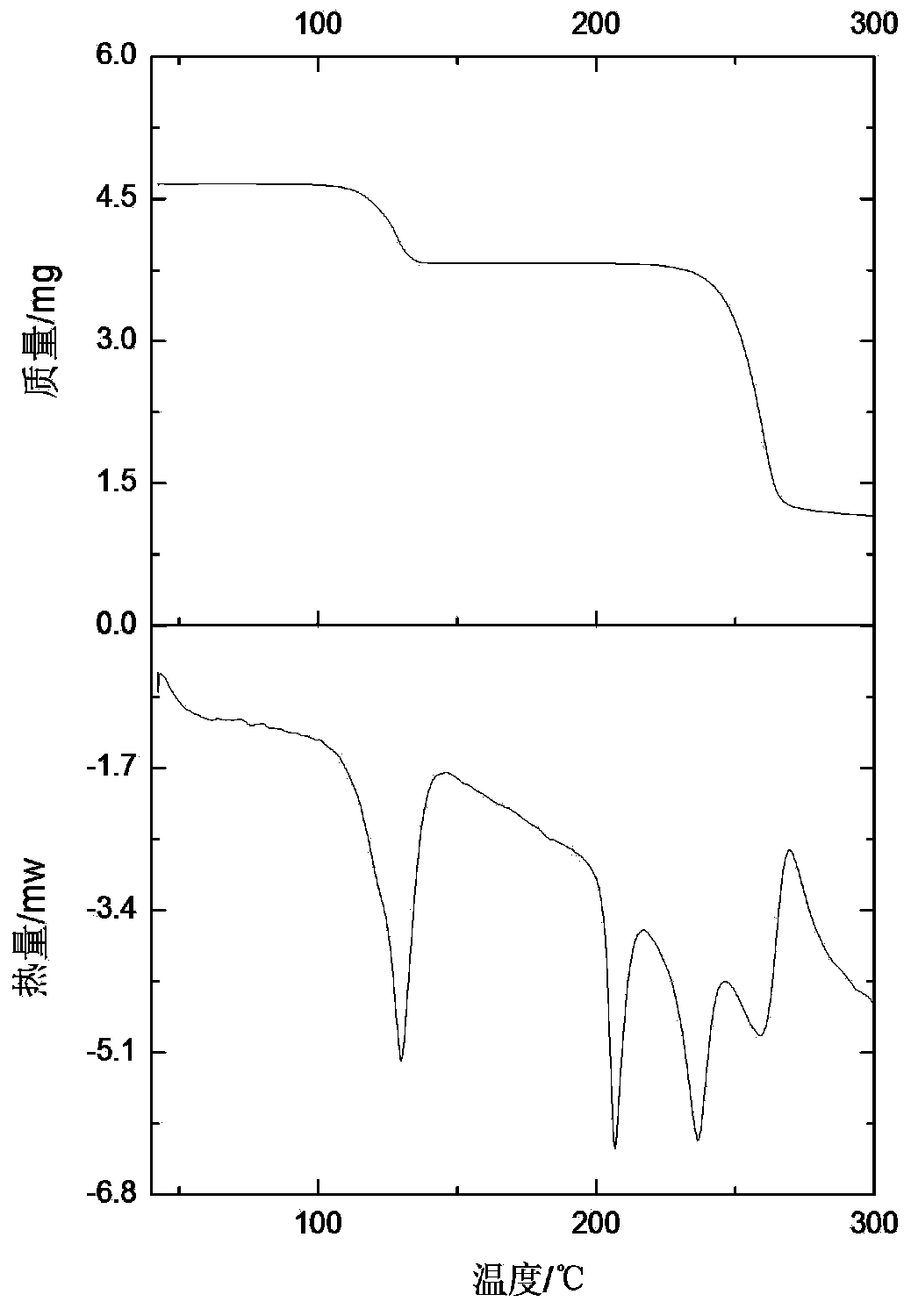

Embodiment 2

[0027] After 72.80g of APPP and 40.8g of TCNQ were dissolved in chlorobenzene solvent, after standing still for 24 hours, the solvent was removed under vacuum and decompression, and the porous composite material was obtained by drying.

Embodiment 3

[0029] 72.80g APPP and 40.8g TCNQ were dissolved in a mixed solvent of toluene and chlorobenzene (volume ratio 1:1), and after standing still for 24 hours, the solvent was removed under vacuum and dried to obtain a porous composite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com