Surface cleaning device

A technology for surface cleaning devices and adjusting discs, applied in cleaning methods and tools, cleaning methods using tools, brushes, etc., can solve problems such as high cost, health hazards to workers, and low work efficiency, and achieve high automation and dust removal Good effect and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

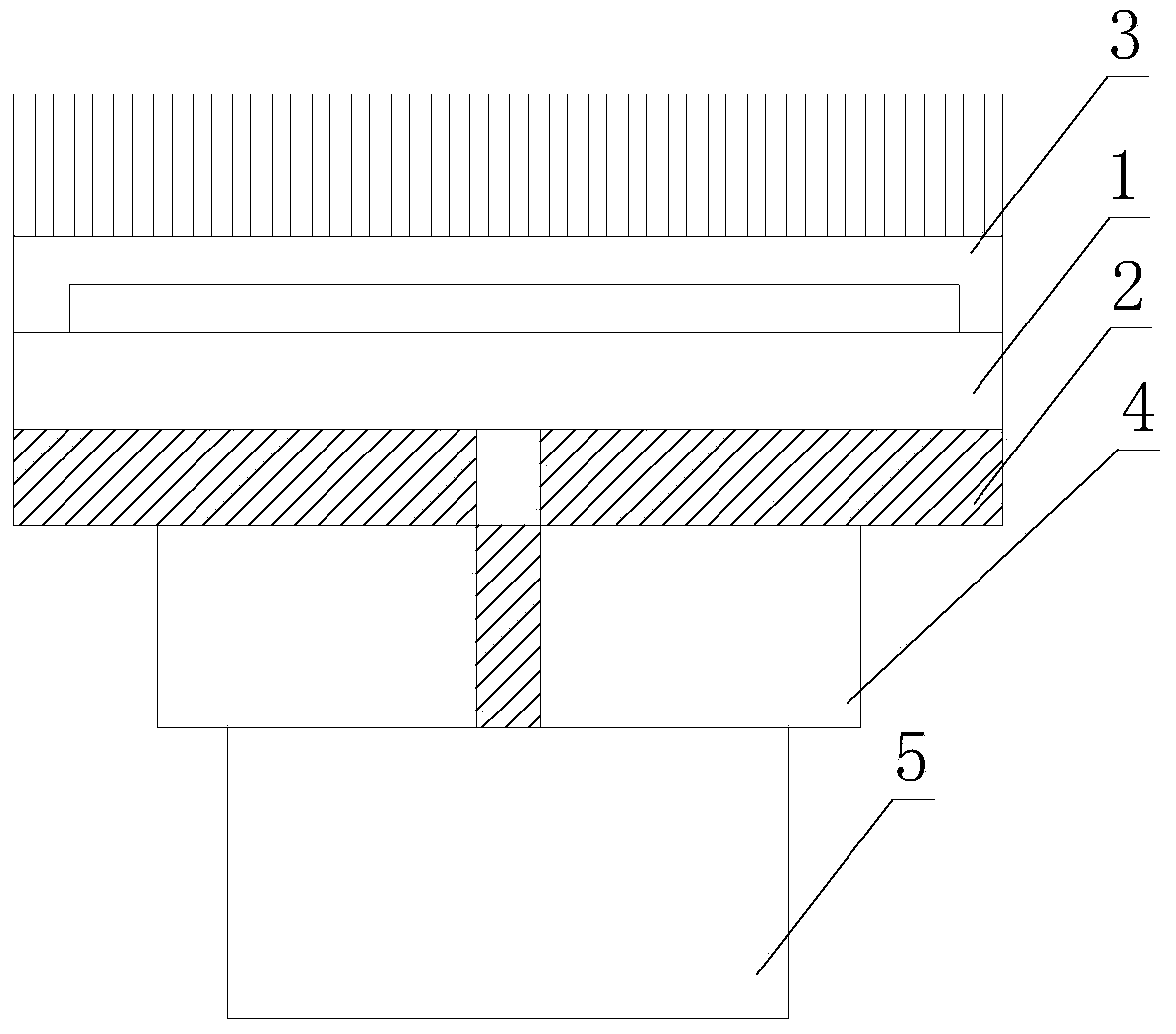

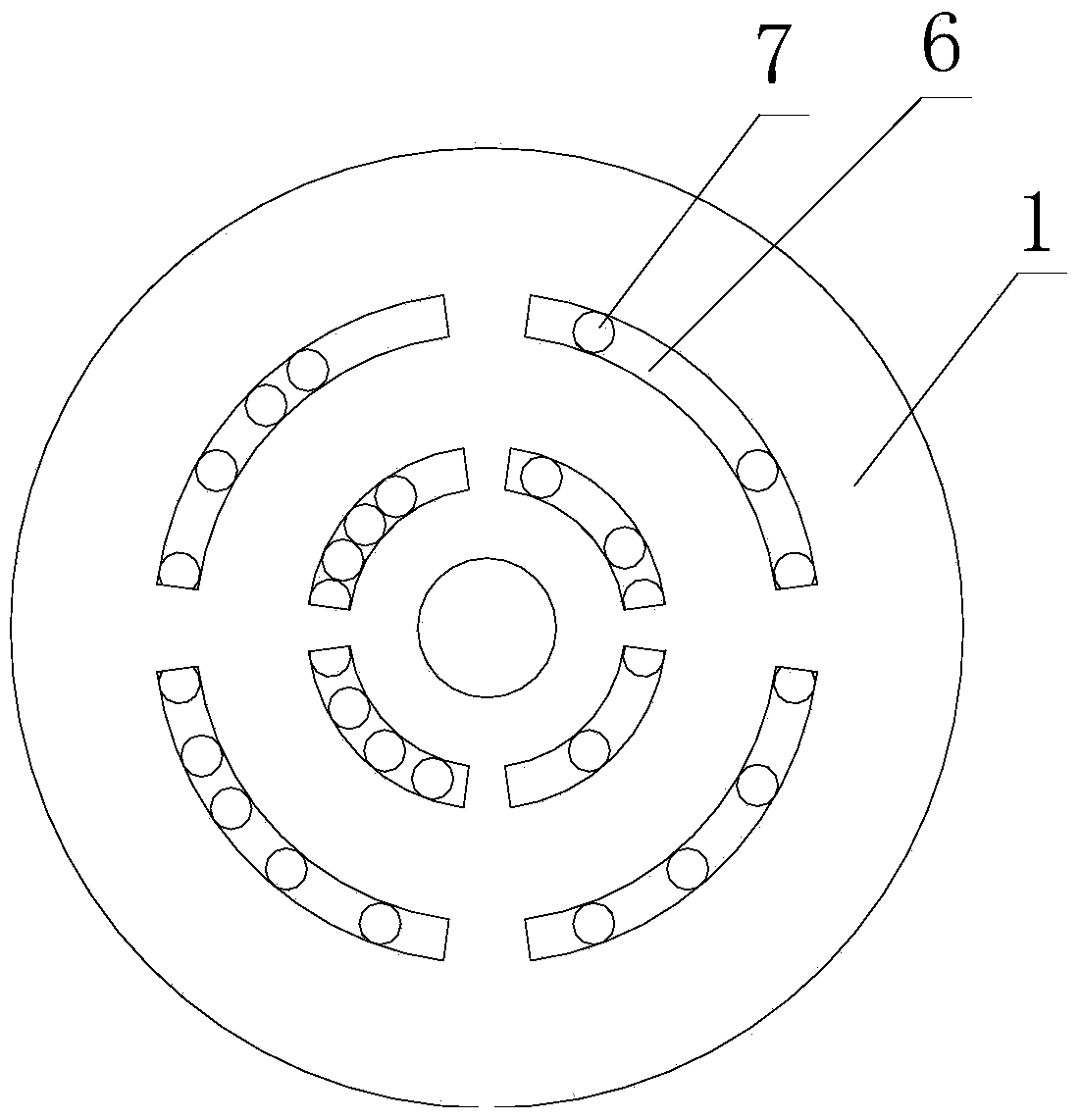

[0011] like figure 1 and figure 2 as shown, figure 1 It is a partial schematic diagram of a surface cleaning device proposed by the present invention; figure 2 for figure 1 sectional schematic diagram.

[0012] refer to figure 1 and figure 2 In one embodiment, a surface cleaning device proposed by the present invention includes a rotating disk 1, an adjusting disk 2, a bristle holder 3, an air extraction mechanism 4 and a driving mechanism 5, and the rotating disk 1 is located above the adjusting disk 2 and two The center of the rotating disc 1 is provided with a first through hole, the center of the adjusting disc 2 is provided with a second through hole, the output shaft of the driving mechanism 5 is rotatably connected with the adjusting disc 2 through the second through hole and passed through the first The through hole is fixedly connected with the rotating disk 1, the rotating disk 1 has at least one cavity 6 running through its thickness direction, the adjustin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap