a large cargo aircraft

A kind of aircraft, large-scale technology, applied in the direction of aircraft parts, aircraft accessories, aircraft power plant, etc., can solve the problems of affecting fuel load and voyage, low cruise efficiency, high fuel consumption rate, etc., to achieve increased fuel load and The effects of range, improved cruising efficiency, and reduced weight factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

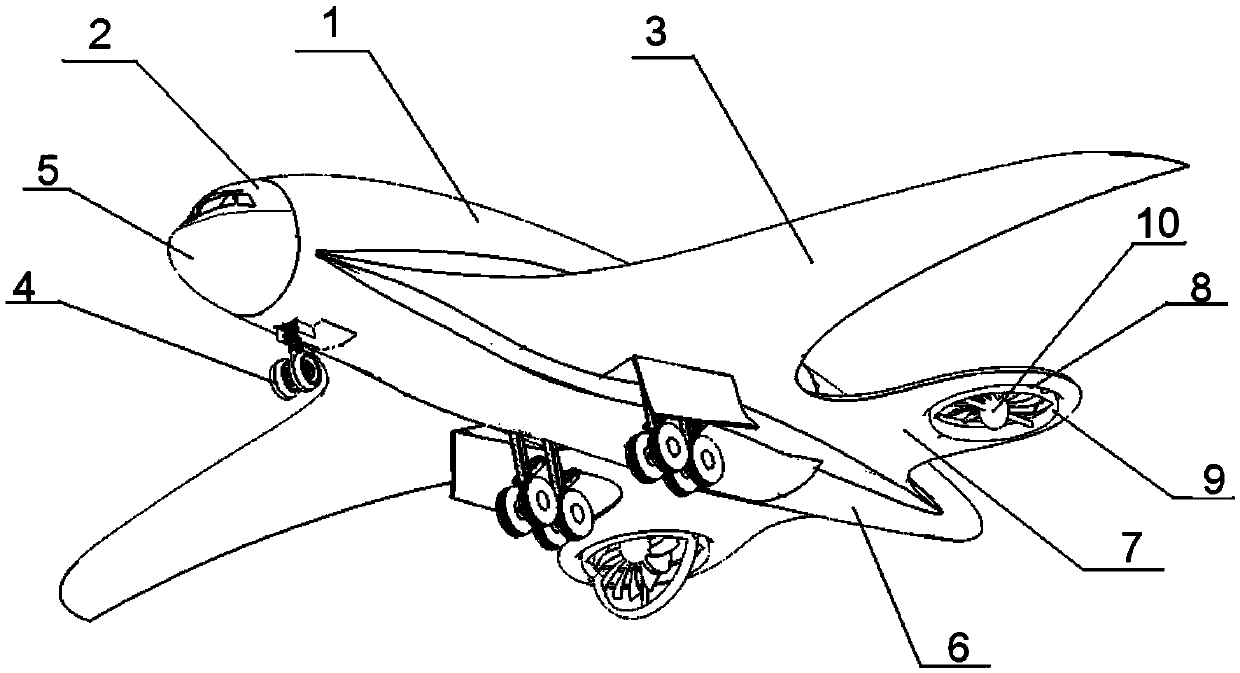

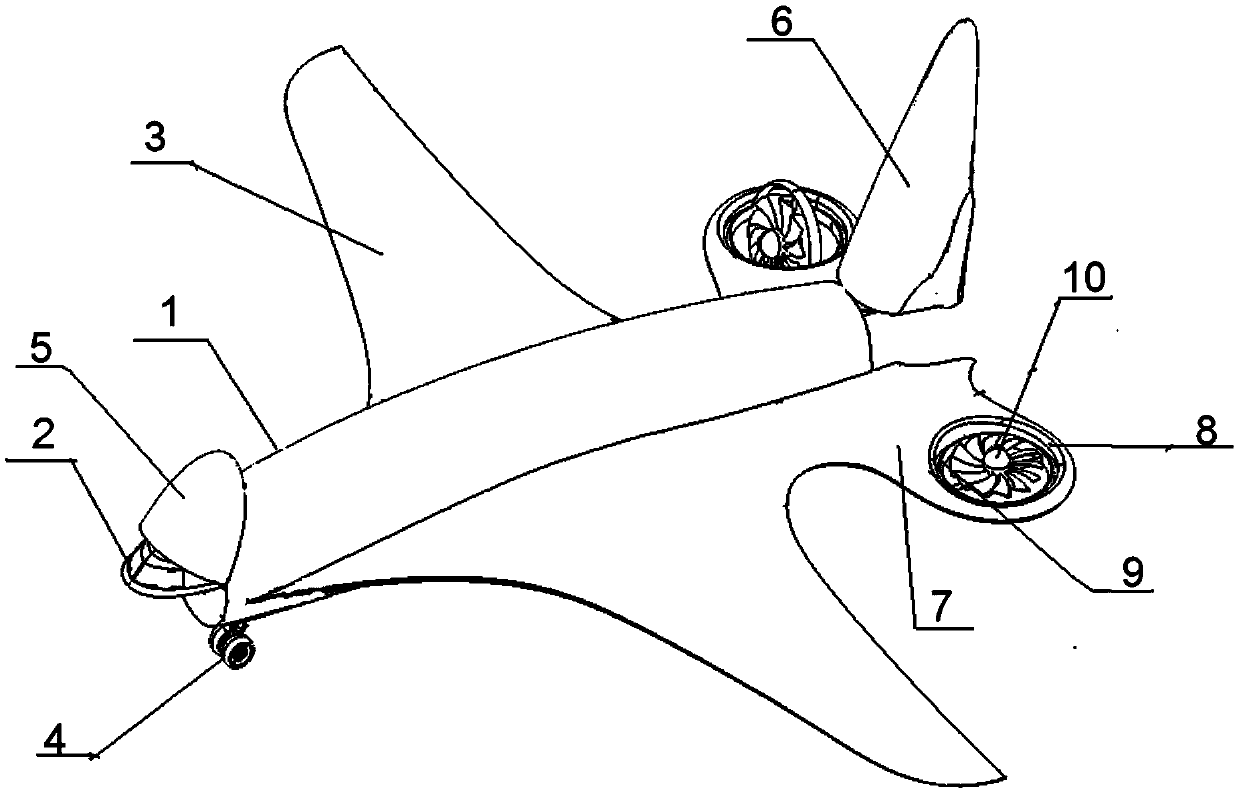

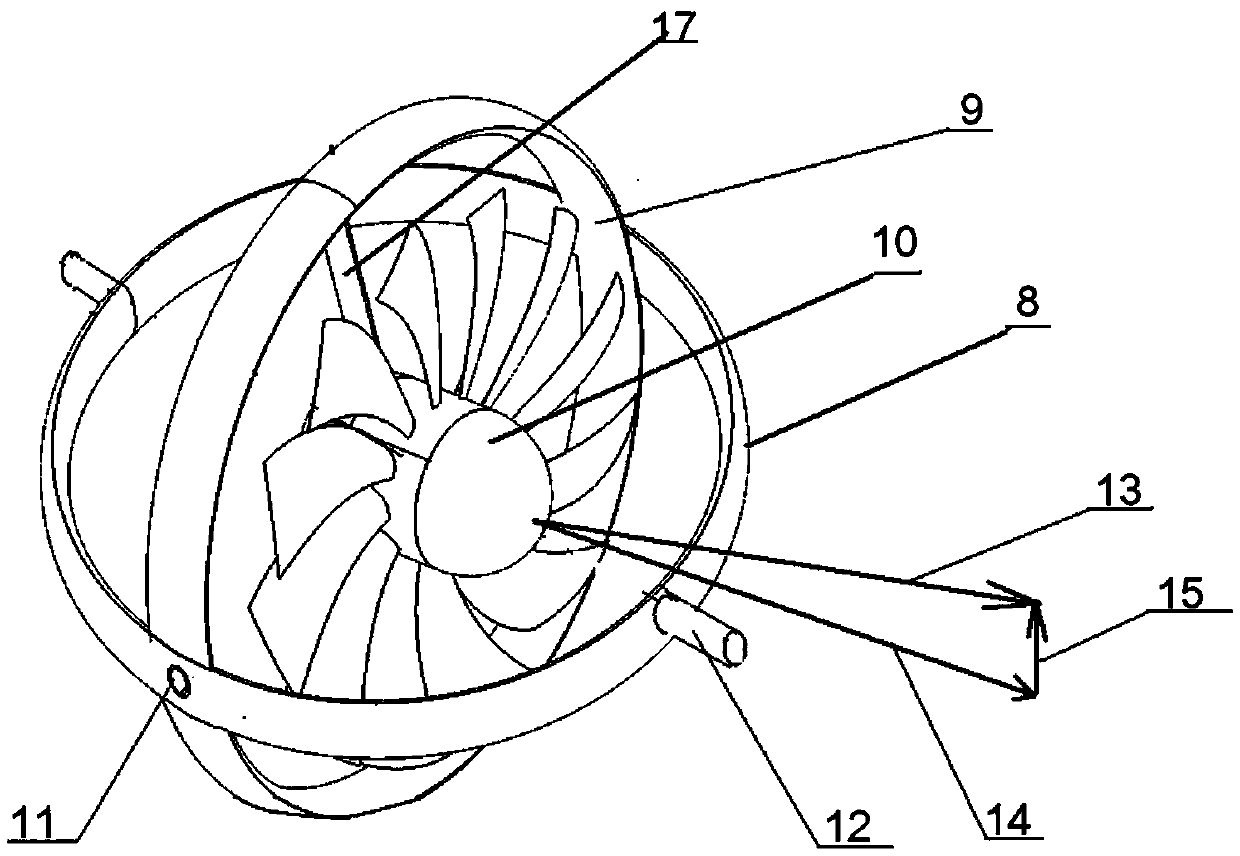

[0013] The present invention will be described in further detail below. see Figure 1 to Figure 4 , a layout of a large cargo aircraft, including a fuselage 1, a cockpit 2, a wing 3 and a retractable tricycle landing gear 4, the wing root of the wing 3 is connected to the side middle of the fuselage 1 as a whole, and its characteristics in:

[0014] (1) The cockpit 2 is located on the upper part of the nose. The height of the cockpit 2 is 1 / 3 of the total height of the nose. The bottom of the cockpit 2 is provided with a cockpit floor. Connected as a whole, the lower part of the nose is the cargo hold front door 5 that can be turned up, and a composite hinge is arranged at the maximum width position on both sides of the rear end of the cargo hold front door 5. The profile and the exterior profile of the cockpit 2 and the front end of the fuselage 1 form an integral smooth profile. When the cargo compartment front door 5 needs to be opened, under the action of the operating m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com