A plastic reel

A plastic wire reel and wire reel technology, applied in the field of plastic wire reels and their assembly structures, can solve the problems of easily damaged cables, expensive iron wire reels, easy to rust, etc., achieve short production cycle and reduce production cost, ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

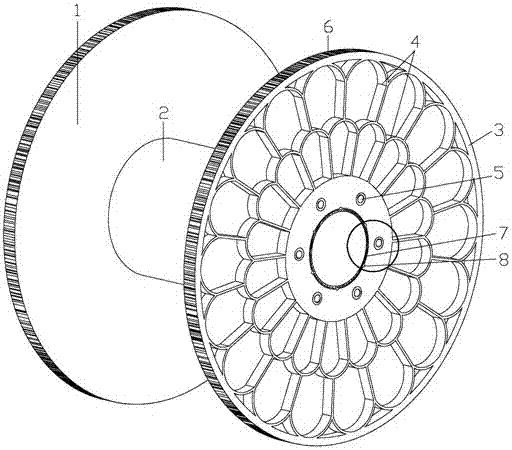

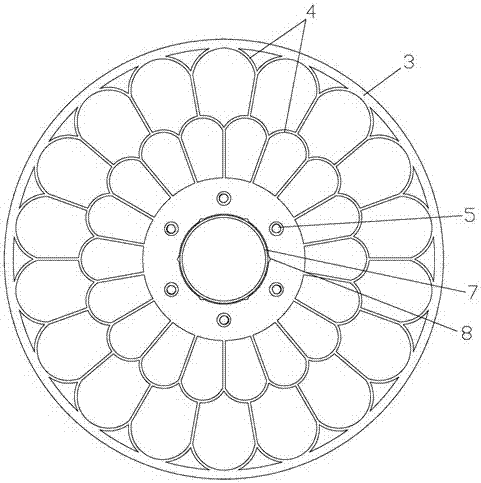

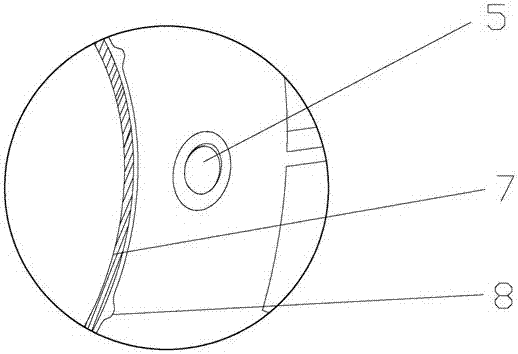

[0022] The novel spool of the present invention comprises a spool cylinder 2 and spool disks 1 and 3 connected to both ends of the spool cylinder 2, the spool cylinder 2 is in the shape of a cylinder, and there are concave-convex reinforcing ribs in the cylinder for connection support and Strengthening effect; the wall thickness of the entire cylinder is 3MM; the outer diameter of the cylinder is 50MM; the inner diameter of the cylinder is 10MM; the height of the cylinder is 100MM. There is a cylindrical through hole on the concave-convex rib inside the cylinder, with a diameter of 10MM. The wire reel cylinder 2 is provided with a turning reinforcing rib 8, which is configured along the circumferential direction of the wire reel, and the quantity can be set to 1; to prevent the wire reel cylinder 2 from rotating radially when connected with the wire reel discs 1 and 3. The wire reel cylinder 2 and the wire reel discs 1 and 3 are fixedly connected by screws 5, and the wire reel...

Embodiment 2

[0024] The novel reel of the present invention comprises a reel cylinder 2 and reel discs 1 and 3 connected to both ends of the reel cylinder 2, the reel 2 is in the shape of a cylinder, and there are concave-convex wall reinforcing ribs in the cylinder for connection, support and reinforcement , The wall thickness of the entire cylinder is 8MM; the outer diameter of the cylinder is 350MM; the inner diameter of the cylinder is 200MM; the height of the cylinder is 690MM. There are cylindrical through holes on the concave-convex reinforcing ribs inside the cylinder, with a diameter of 22MM; the reel cylinder 2 is provided with a rotation reinforcing rib 8, which is arranged along the circumferential direction of the reel, and the number is 20; to prevent the reel cylinder 2 and the reel circle When disks 1 and 3 are connected, they rotate radially. The wire reel cylinder 2 and the wire reel discs 1 and 3 are fixedly connected by screws 5, and the wire reel discs 1 and 3 are prov...

Embodiment 3

[0026] The novel reel of the present invention comprises a reel cylinder 2 and reel discs 1 and 3 connected to both ends of the reel cylinder 2, the reel 2 is in the shape of a cylinder, and there are concave-convex wall reinforcing ribs in the cylinder for connection, support and reinforcement , The wall thickness of the entire cylinder is 30MM, the outer diameter of the cylinder is 1500MM, and the inner diameter of the cylinder is 1400MM. The cylinder height is 5000MM. There are cylindrical through holes on the concave-convex reinforcing ribs inside the cylinder, with a diameter of 100MM. The rotating reinforcing ribs 8 are arranged on the coil cylinder 2, arranged along the circumferential direction of the coil, and the number can be set to 50; to prevent the coil cylinder 2 and the wire When the discs 1 and 3 are connected, they rotate radially. The wire reel cylinder 2 and the wire reel discs 1 and 3 are fixedly connected by screws 5, and the wire reel discs 1 and 3 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com