Installation method of serial type bell-less furnace top charging equipment of center of super-huge type blast furnace

A furnace top charging and equipment installation technology, applied in the direction of bell and funnel arrangement, etc., can solve the problems of not meeting the rapid overhaul period, the large size of the weighing tank and the ring beam of the rotating tank, and the lifting to the top of the furnace.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

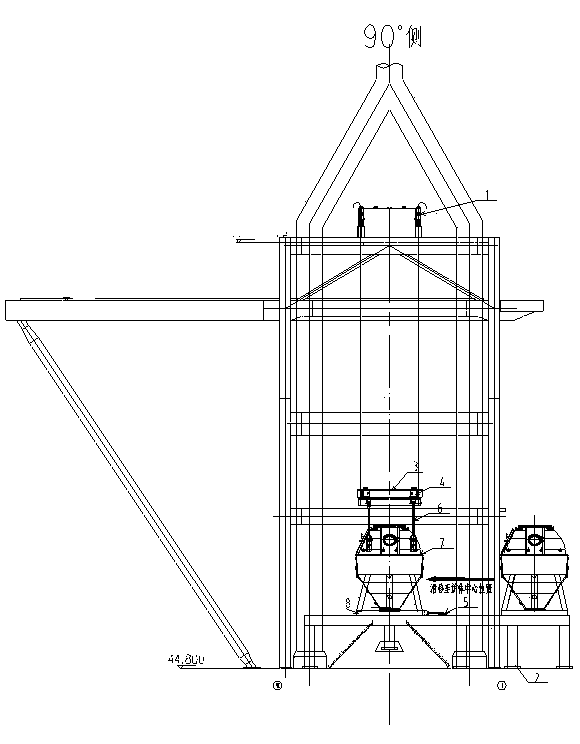

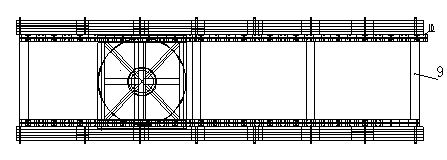

[0024] Such as figure 1 Shown, the present invention a kind of extra-large blast furnace center string tank type bellless furnace roof charging equipment installation method, it comprises: the sliding beam of furnace roof equipment and the following steps:

[0025] Step 1, complete the installation of four sets of vertical lifters 1 for furnace top equipment before shutdown;

[0026] Step 2, the vertical lifters of the four sets of furnace top equipment have been debugged;

[0027] Step 3, after installing the new furnace shell with the furnace shell lifter, it is necessary to remove the upper furnace shell lifter, and then install the sliding beam 2 of the furnace top equipment;

[0028] Step 4, after the assembly of the rotating ring beam 3 is completed on the ground, the special hoisting sling 4 is welded on it, and then hoisted to the slip beam with a crawler crane; Center of blast furnace body;

[0029] Step 5, the four sets of furnace top equipment vertical lifter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com