Rod penetrating type lifting scaffold

A technology for lifting scaffolding and piercing rods, which is applied in the direction of scaffolding for building structure support, building structure support, building structure support, etc., can solve the problems of large manpower consumption, high cost, and large investment at one time, and achieve less consumption of steel pipes, The effect of saving electricity resources and saving investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

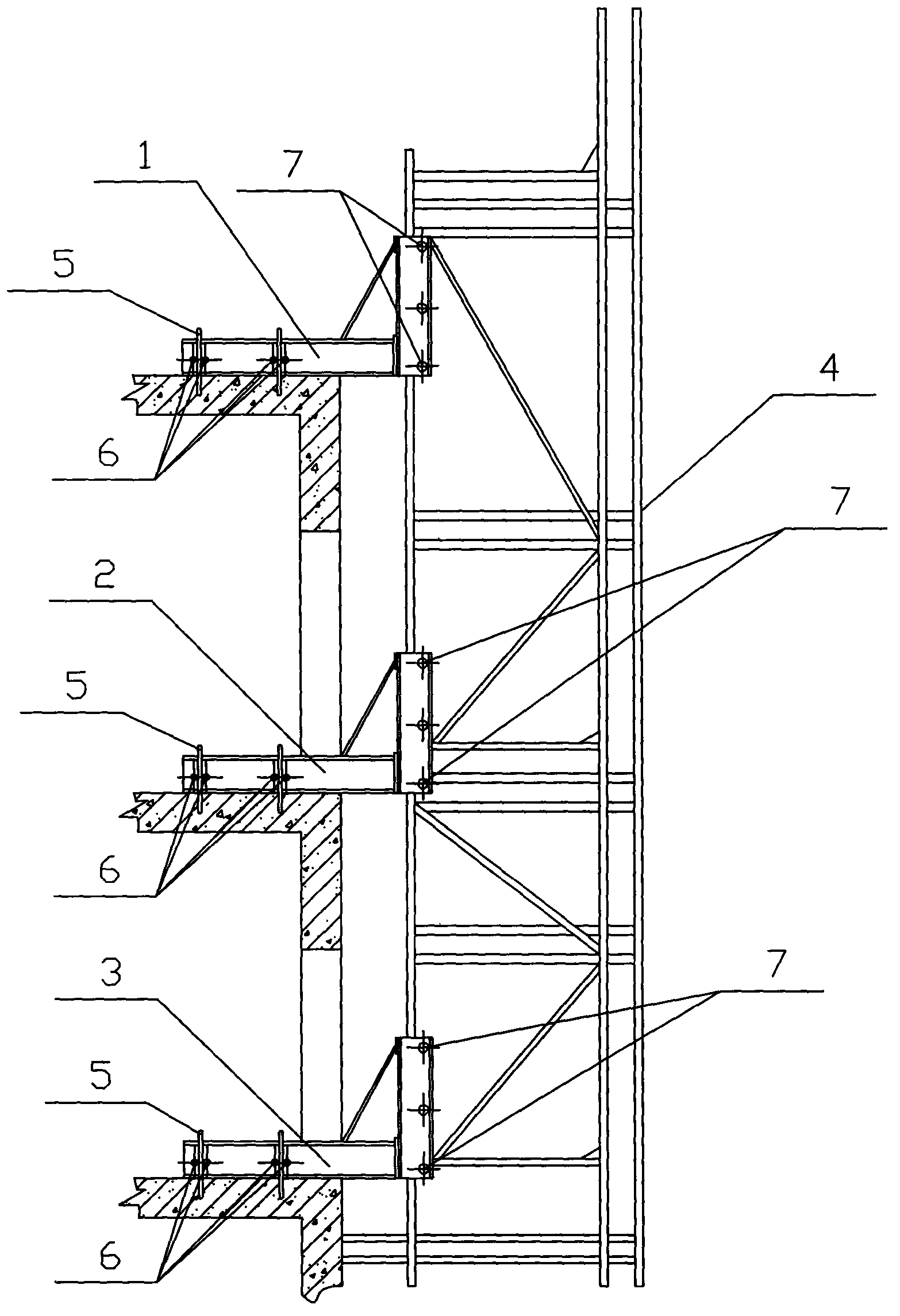

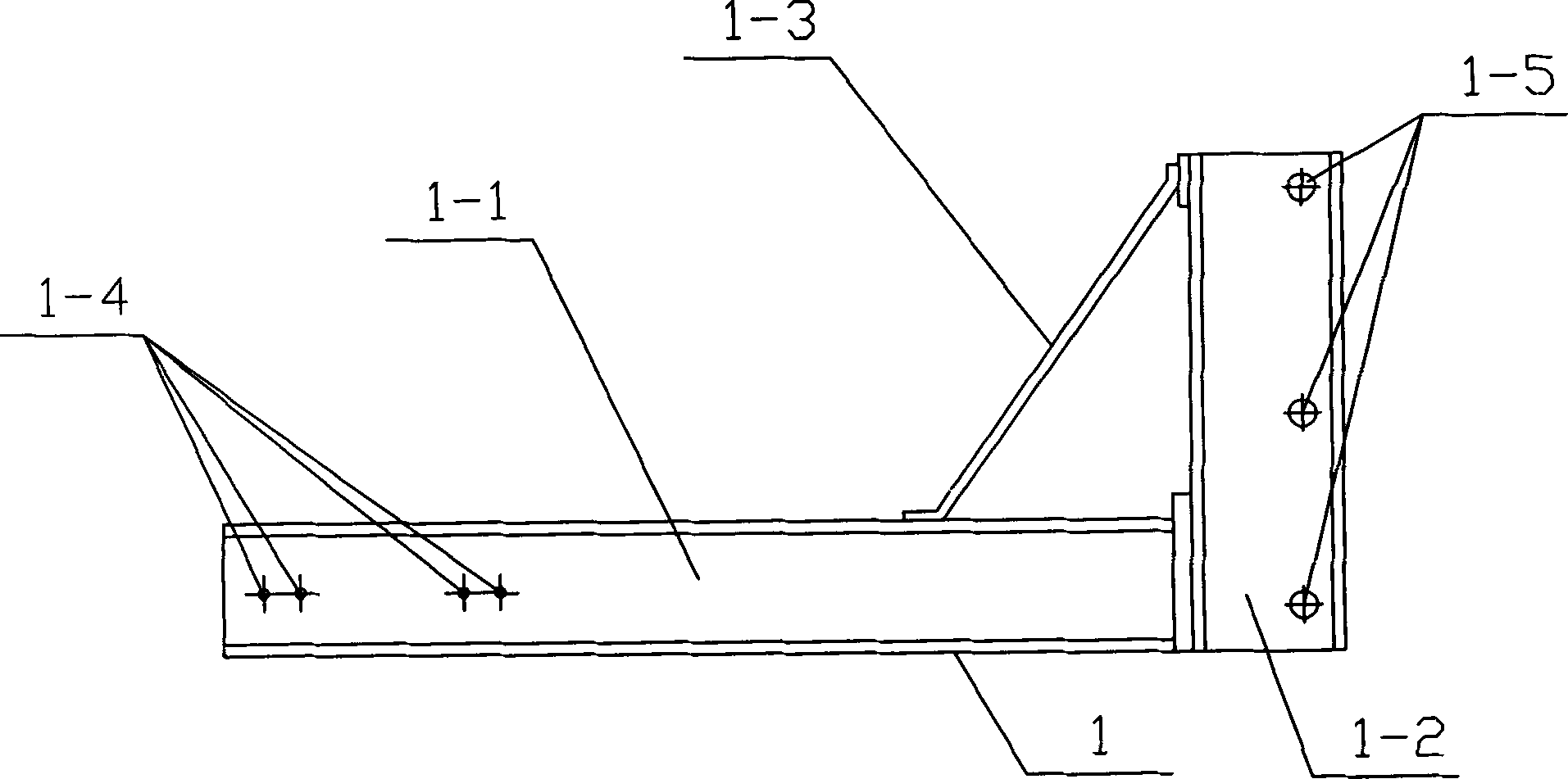

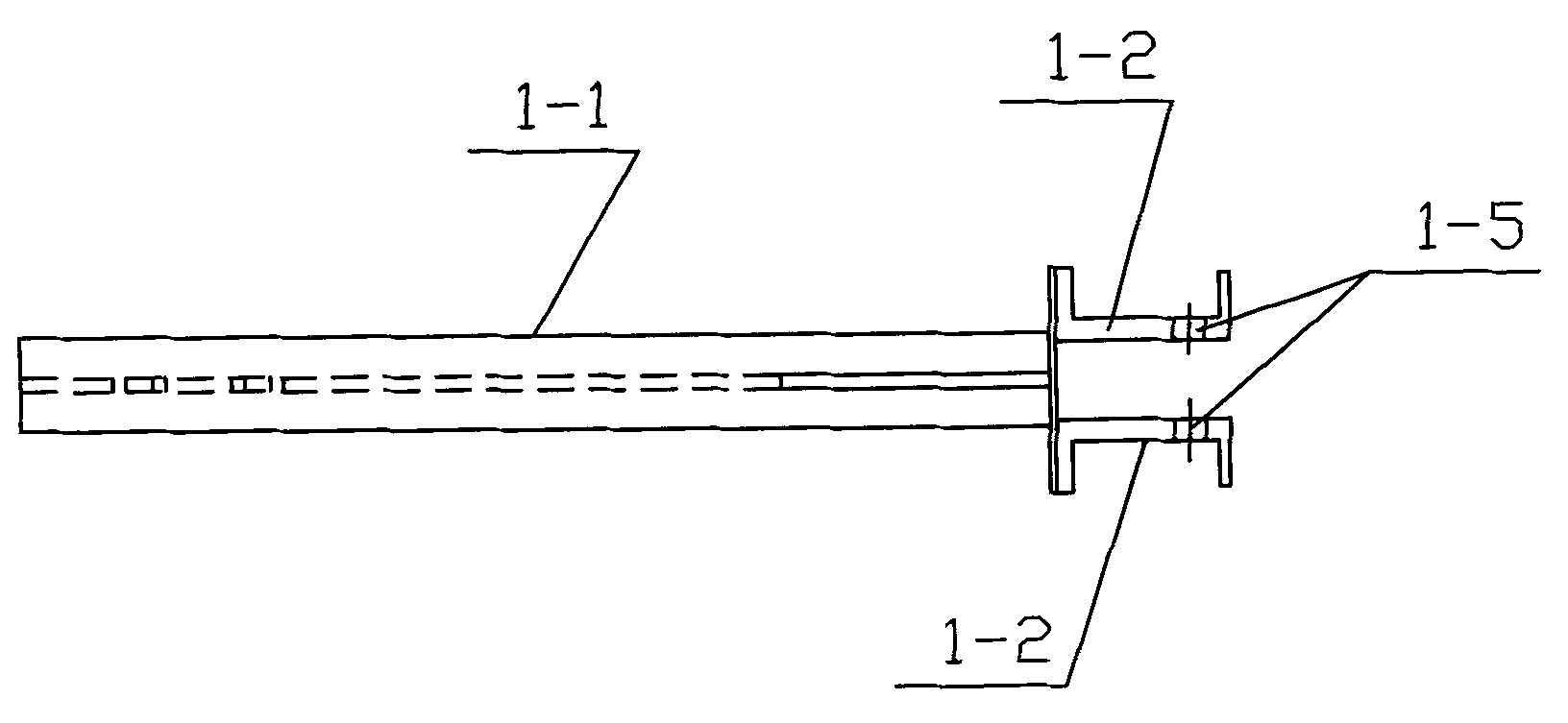

[0029] see Figure 1-12 , the specific embodiment adopts the following technical scheme: it comprises the first track 1, the second track 2, the third track 3 and the bearing frame 4; the structures of the first track 1, the second track 2 and the third track 3 are the same, and the A track 1 includes I-beam 1-1, channel steel 1-2, reinforcing rib 1-3, fixing hole 1-4 and limit fixing hole 1-5, and I-beam 1-1 is perpendicular to channel steel 1-2 set, and one end of the I-beam 1-1 is welded on one side of the channel steel 1-2, a reinforcing rib 1-3 is arranged between the I-beam 1-1 and the channel steel 1-2, and the I-beam 1-1 Two sets of fixing holes 1-4 are arranged horizontally on the upper side, and several limit fixing holes 1-5 are vertically arranged on the channel steel 1-2, and the first track 1, the second track 2 and the third track 3 pass through the I-beam 1 -1 is inserted into the inside of the pre-embedded U-shaped part 5, and the pre-embedded U-shaped part 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com