Locomotive servicing work platform

A locomotive maintenance and operation platform technology, which is applied in the direction of industrial construction, etc., can solve the problems of high labor intensity, high labor cost, and low work efficiency, and achieve the effects of improving efficiency, improving safety, and avoiding injuries caused by foreign objects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

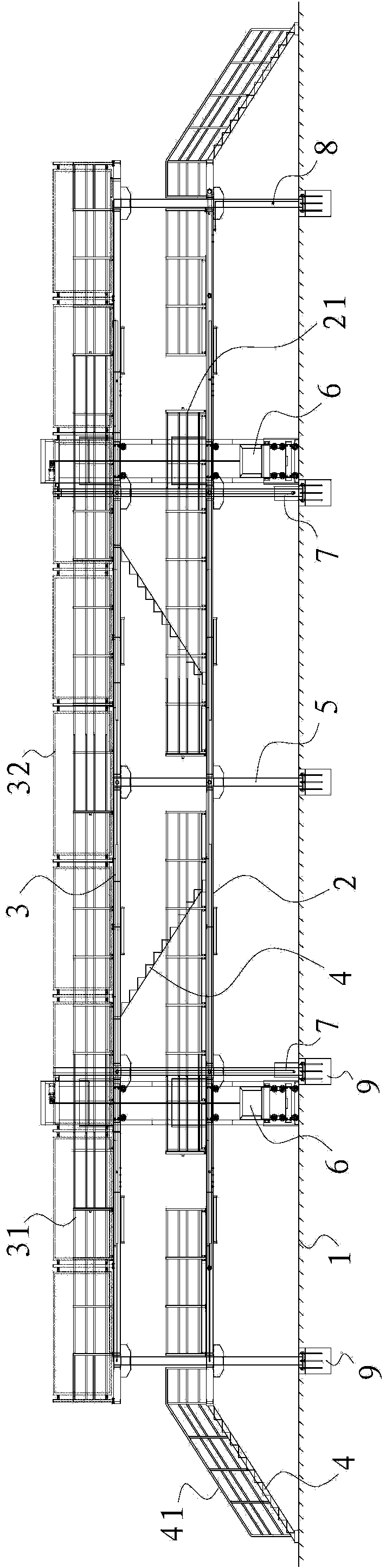

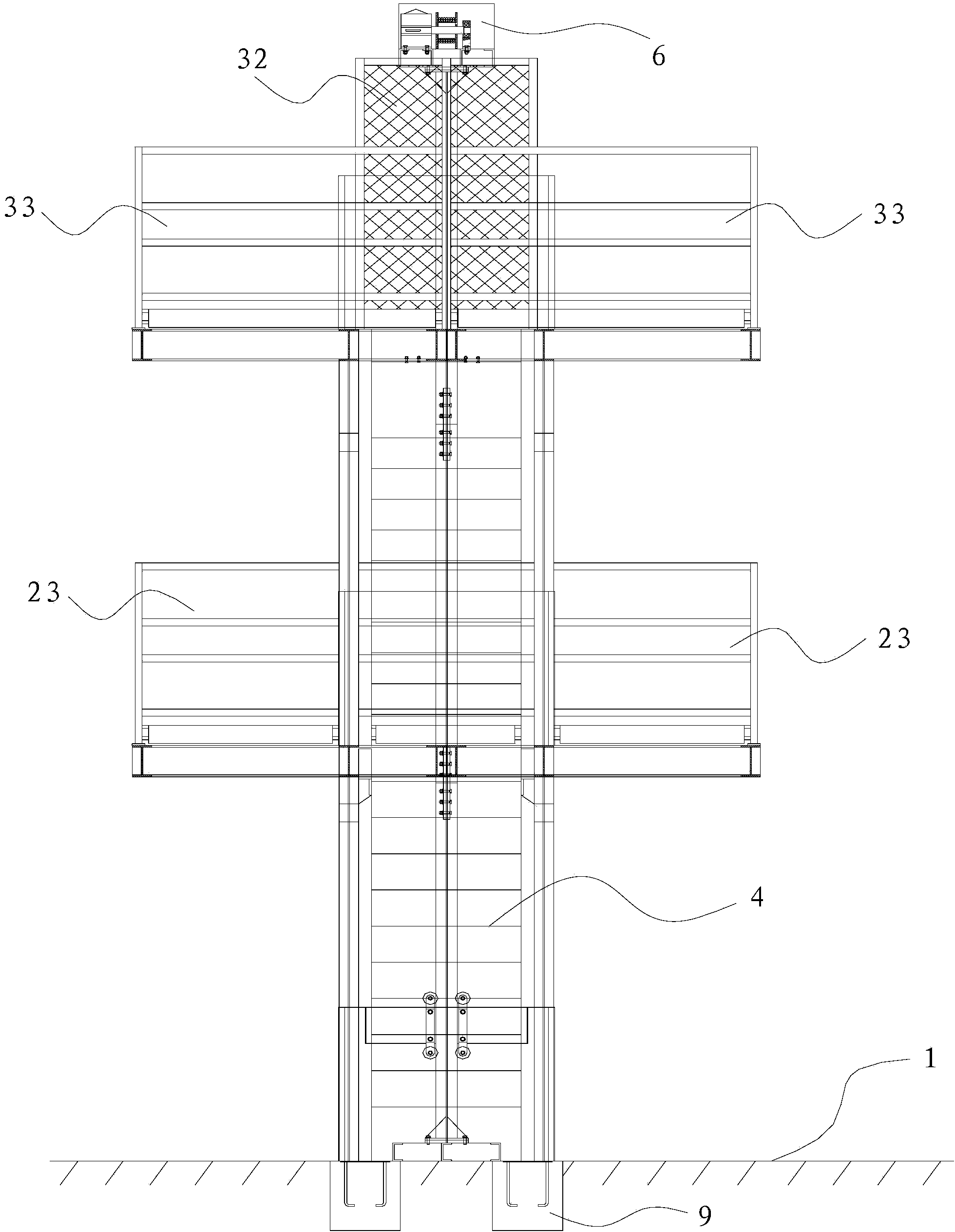

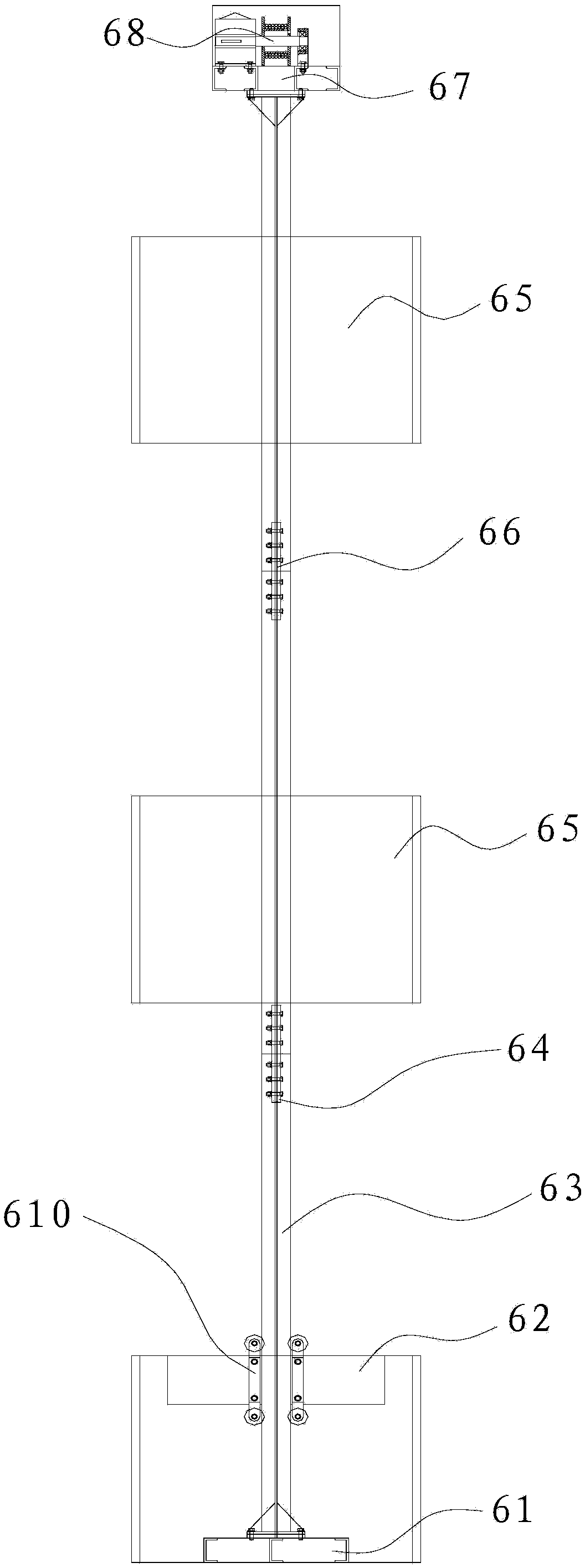

[0024] The preferred embodiment discloses a locomotive maintenance work platform. Such as figure 1 with figure 2 As shown, the platform includes five support columns 5, and the bottom ends of the support columns 5 are fixed on the installation surface 1 through the base 9; The two side surfaces of 2 protrude from the support column 5, respectively forming the second-floor maintenance operation channel 23; There are at least one group of lifting device 6, a power supply box 7 and a water switch 8, and the lifting device 6 is used for vertically transporting materials (accessories and tools) for locomotive maintenance operations; A staircase 4 is arranged between the first-floor workbench 2 and the third-floor workbench 3 . The installation surface 1 is the ground.

[0025] Use the lifting device 6 to carry the accessories and tools to the second-floor operation platform 2 or the third-layer operation platform 3, and the workers go up and down from the stairs 4, which impro...

Embodiment 2

[0030] This preferred embodiment discloses a locomotive maintenance work platform, the structure of which is basically the same as that of the first preferred embodiment. The platform includes at least three support columns fixed on the installation surface through the base. The support columns are provided with a second-floor operation table and a third-layer operation table. Operation channel; the two sides of the three-layer operation platform protrude from the support column to form a three-layer maintenance operation channel; attached to the support column, there are at least one set of lifting devices, a power box and a water switch, and the lifting device is used for vertical transportation. Materials for locomotive maintenance operations; stairs are provided between the installation surface and the second-floor operating platform, and between the second-floor operating platform and the third-floor operating platform.

[0031] The difference is that: the specific number...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com