Method for controlling running of water-cooled screw-type refrigerating unit

A refrigeration unit and operation control technology, which is applied in the field of air conditioning and refrigeration, can solve the problems of ineffective energy saving and low efficiency of cooling water pumps, and achieve the effect of saving energy consumption and reducing the total energy consumption of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

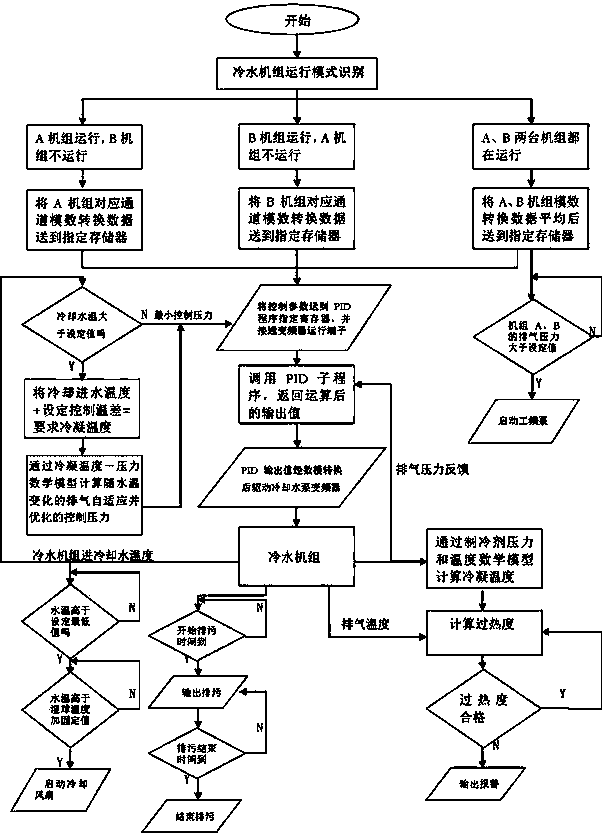

[0035] figure 1 The operation control method of the water-cooled screw refrigerating unit shown in includes the following steps:

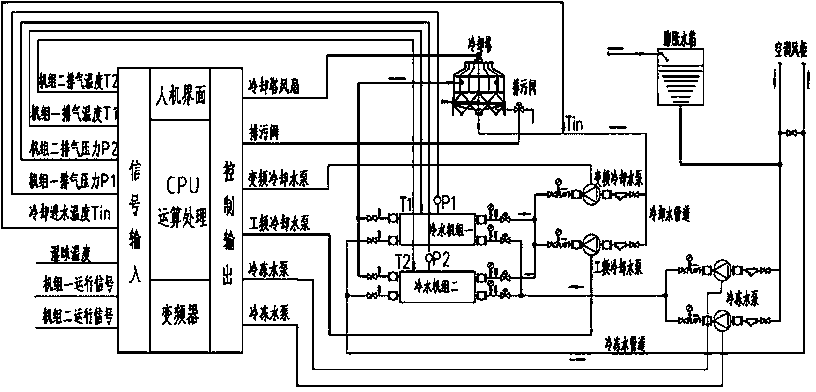

[0036] (1) Unit operation mode detection: Detect the operation mode of refrigeration units with one use and one standby. When unit A is running and unit B is out of service, start a variable frequency pump to drive unit A, detect the exhaust pressure value of unit A, and when unit B When unit A is out of operation, start a variable frequency pump to drive unit B, and detect the exhaust pressure value of unit B. When unit A and unit B are running at the same time, start the variable frequency pump and power frequency pump to drive unit A and unit B respectively. The average pressure of the two units is taken as the exhaust pressure value; the exhaust pressure value is sent to the memory as the real-time feedback valu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com