Visual fire door of cement brick making kiln

A furnace door and brick furnace technology, which is applied in the field of visualized furnace doors, can solve problems such as inconvenience of operation, operators cannot directly view furnace operation conditions, etc., and achieve the effects of convenient operation, ensuring airtightness, and ensuring explosion-proof performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The detailed structure of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

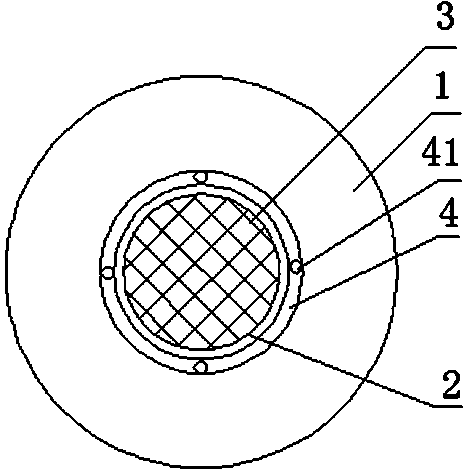

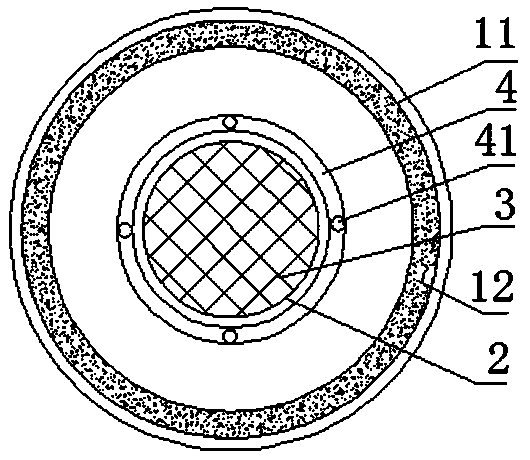

[0020] Such as figure 1 and figure 2 Shown: a visual furnace door for cement brick furnace, including a window in the middle of the furnace door 1, the window is composed of two layers of explosion-proof glass 2 and steel wire mesh 3 welded between the explosion-proof glass 2; two layers of explosion-proof glass 2 They are respectively installed in the first grooves (not shown in the figure) provided on the inner layer and the outer layer of the furnace door 1, and are respectively fixed by the fixing plates 4. Because the inner layer and the outer layer of the furnace door 1 have a certain thickness, the first groove provided in the inner layer and the outer layer is circular, and a circumferential slit is chiseled inward along the radial direction of the circle to form the first groove. The notch of the groove mak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com