Explosion-proof diesel engine

An explosion-proof diesel engine, diesel engine technology, applied in mechanical equipment, engine components, engine starting and other directions, can solve the problems of large volume of hydraulic accumulators, need manual start, high labor intensity, etc., and achieve efficient cleaning, simple structure, and operation. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

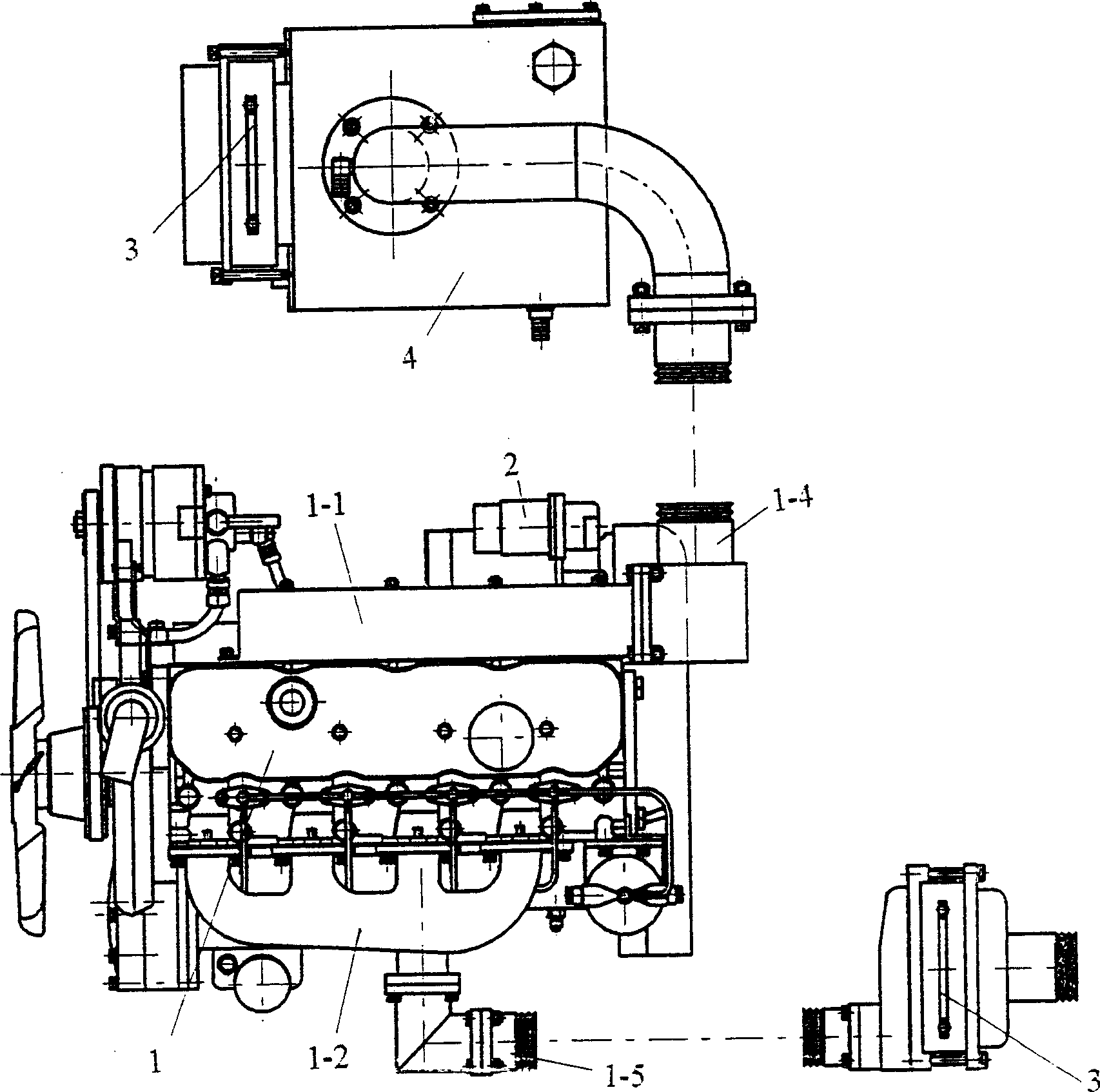

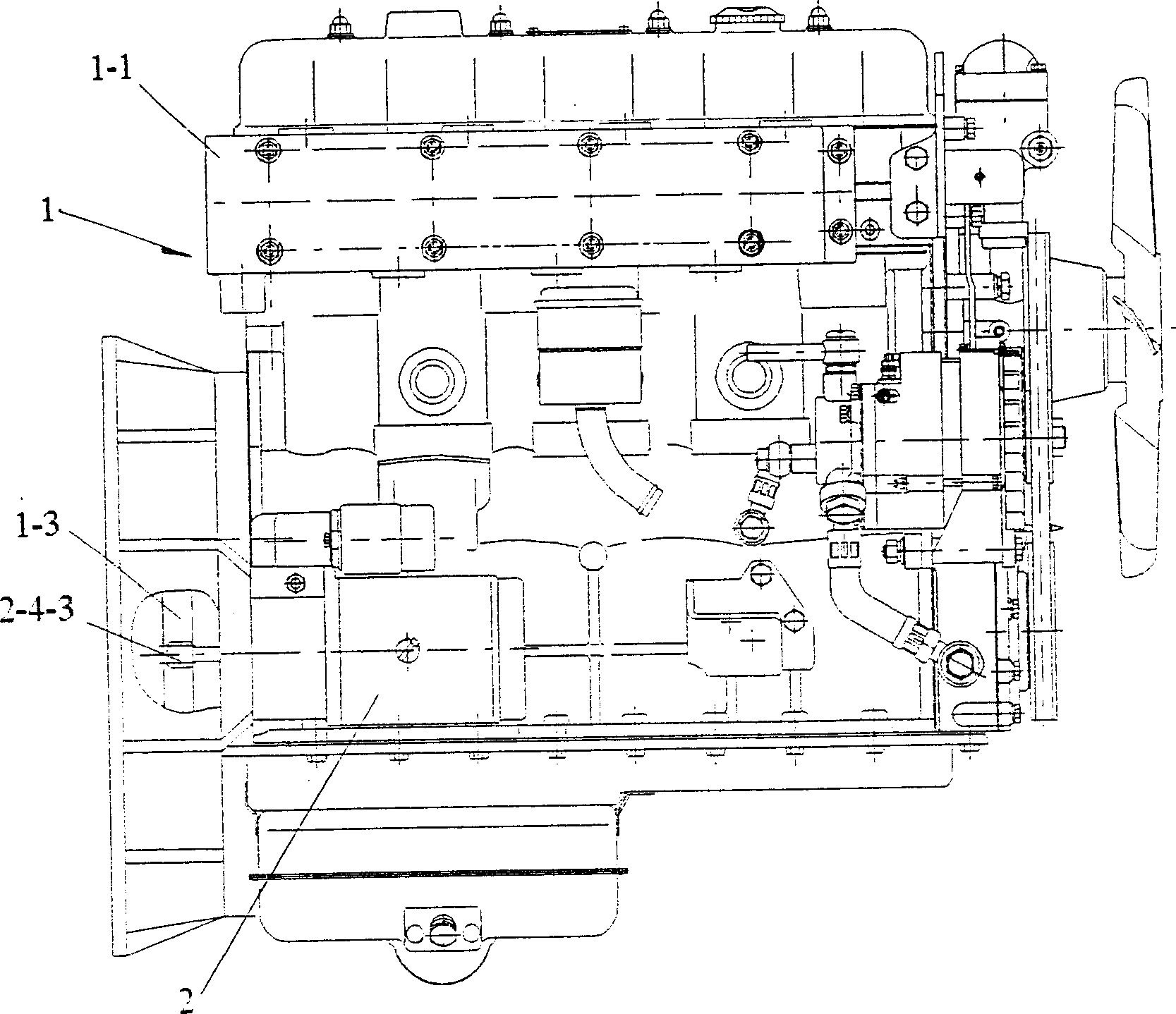

[0045] attached Figure 1~6 The illustrated embodiment has an explosion-proof diesel engine body 1 , an electromagnetically operated forced-engagement starter motor 2 , two explosion-proof fences 3 and an exhaust gas treatment water tank 4 . One of the explosion-proof fences 3 is connected to the intake pipe 1-2 of the diesel engine body 1 by the connecting pipe 1-5, and the other explosion-proof fence 3 is connected to the exhaust port of the waste gas treatment water tank 4, and the waste gas treatment water tank 4 is connected by the waste gas connection pipe 1-2. 4 is connected on the exhaust pipe 1-1 of the diesel engine body 1, and the starter motor 2 is fixed on the body of the diesel engine body 1 and near one end of the flywheel.

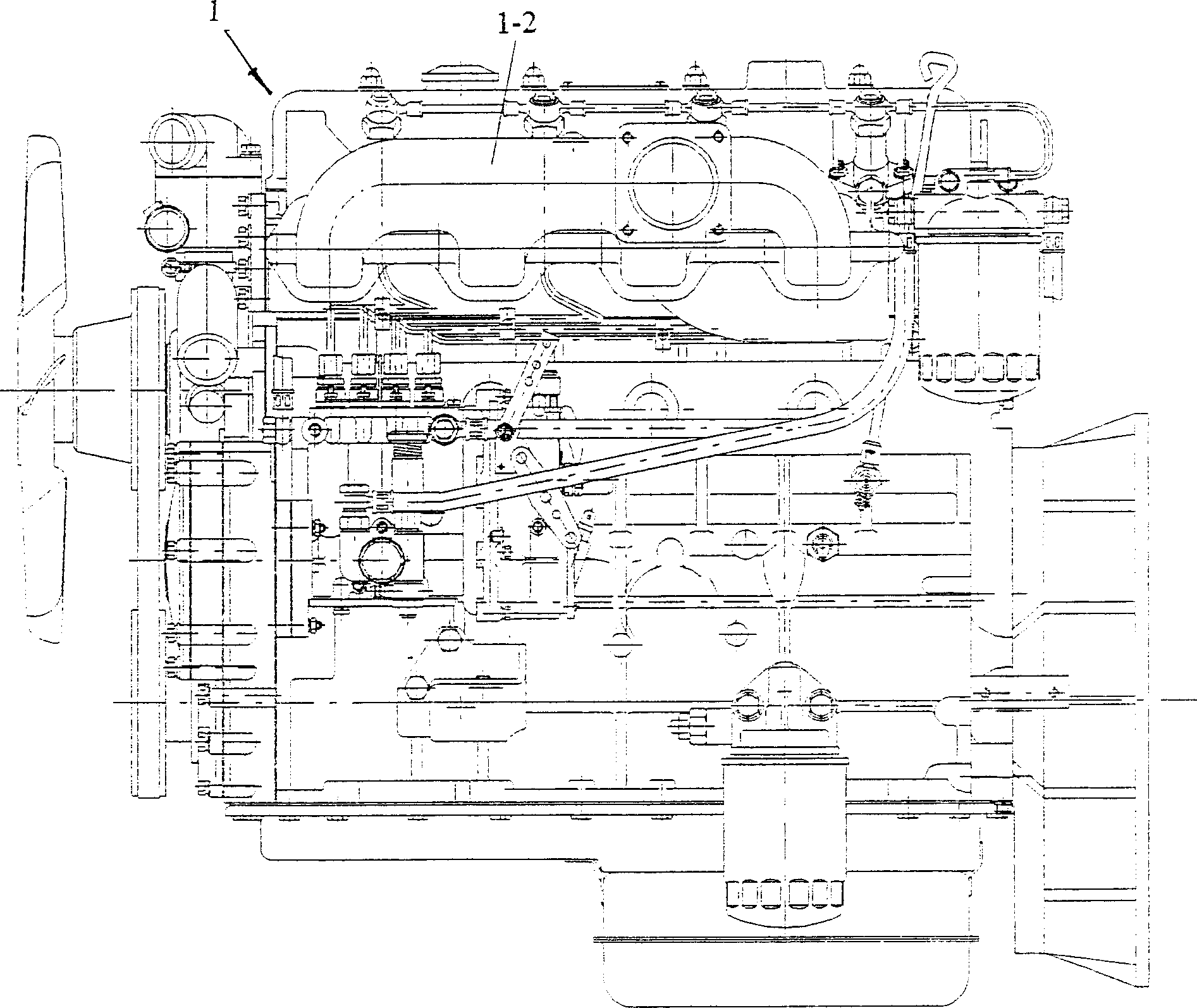

[0046] Diesel engine body 1 (see figure 2 and image 3 ) has a body, a piston, a cylinder, a cylinder head, a crankshaft, a connecting rod, a flywheel, a starting system, a cooling system, a fuel system and a lubrication system. As a di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com