High-efficiency oxygen-enriched combustion multi-element powder heat-conducting oil boiler system

A heat-conducting oil boiler and oxygen-enriched combustion technology, applied in the combustion method, control combustion, combustion equipment and other directions, can solve the problems of high labor intensity of stokers, poor pulverized coal burnout rate, single coal type, etc. and explosion-proof performance, reducing the air excess coefficient, reducing the effect of exhaust gas volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

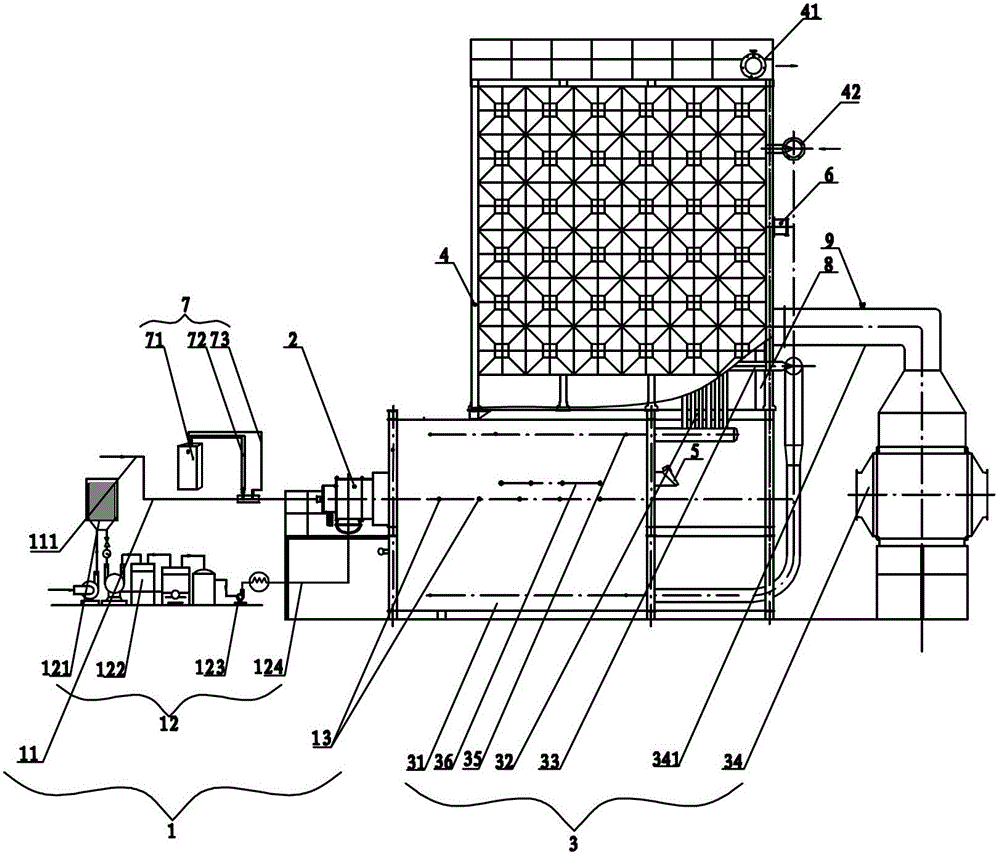

[0023] The high-efficiency oxygen-enriched combustion multi-component heat-conducting oil boiler system of the present invention combines figure 1 , including air intake system 1, burner 2, boiler body 3, boiler body 3 includes combustion chamber 31, radiation heating surface 32 and convection heating surface 33, both radiation heating surface 32 and convection heating surface 33 are tube structure, radiation heating The surface 32 and the convection heating surface 33 are connected in series and installed externally on the outer wall of the combustion chamber 31; the burner 2 is connected to the combustion chamber 31; Wind device 13, primary air inlet device 11 and secondary air inlet device 12 are connected with burner 2 respectively, wherein, primary air inlet device 11 is connected by the middle part of burner 2 through primary air duct 111, and secondary air inlet device 12 Including a membrane oxygen generator 121, an air separator 122, a fan 123 and a secondary air pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com