Photovoltaic module

A photoelectric module and electrical connection technology, applied in the direction of photovoltaic power generation, circuits, electrical components, etc., can solve the problems of increasing module electrical attenuation, adverse effects of module power, etc., and achieve the effect of reducing the risk of electrical attenuation and reducing finger interruption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

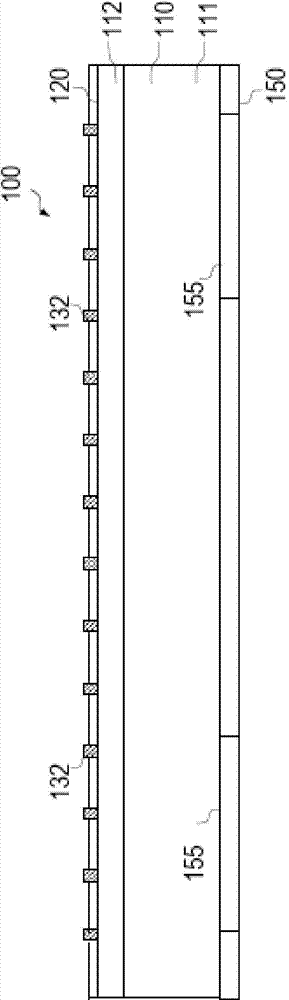

[0023] Solar cells and photovoltaic modules whose improved front-side contact structures are responsible for reducing finger interruptions and cell cracks are described with reference to the accompanying drawings.

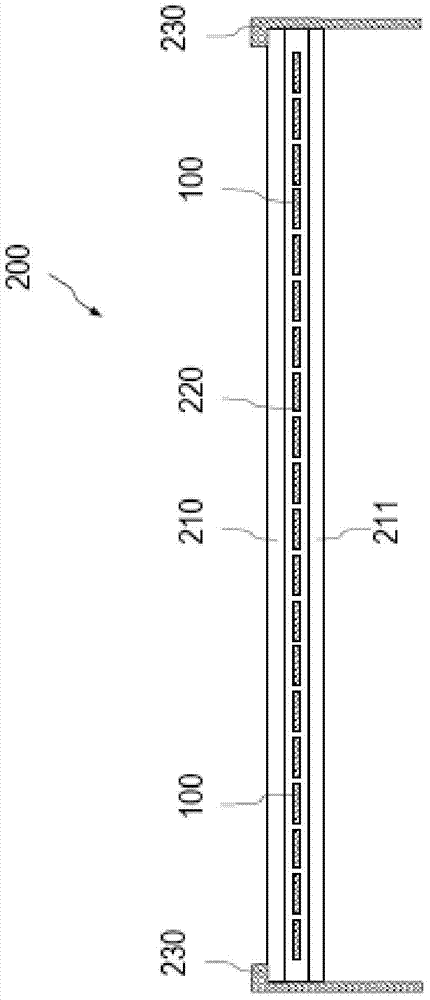

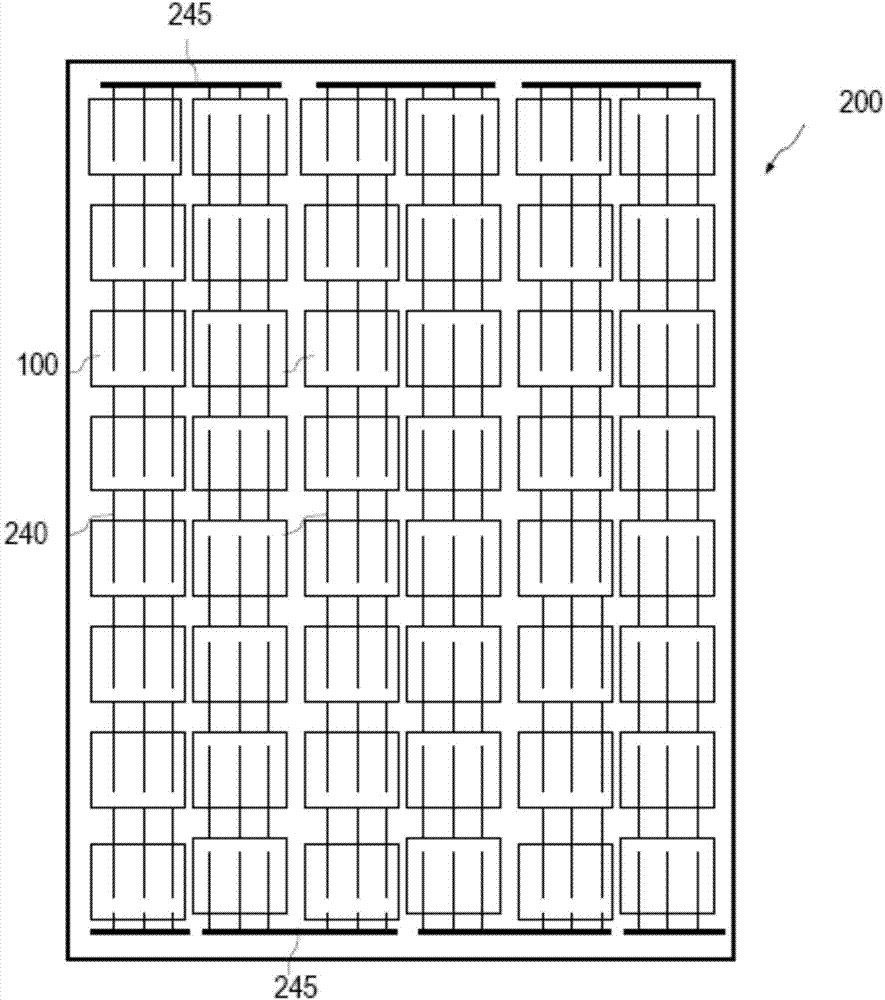

[0024] figure 1 The photovoltaic module 200 is shown in a schematic side view. Figuratively illustrate the attached schematic top view of the front side of the optoelectronic module in figure 2 given in. A photovoltaic module 200 , also referred to below as a solar module, has a number of silicon solar cells 100 that are electrically connected to one another. During operation, the photovoltaic module 200 faces the sun with its front side, a portion of the radiation being absorbed by the solar cells 100 and converted into electrical energy. The solar cell 100 generally has a square structure. However, other shapes can also be realized. The solar cells 100 arranged in a plane in the photovoltaic module 200 are located between the front glass cover 210 and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com