Seeder

A seeder and walk-behind tractor technology, applied to agricultural machinery and implements, shovels, plows, etc., can solve the problems of increasing agricultural production costs, different seeding row spacing, and increasing the burden on farmers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

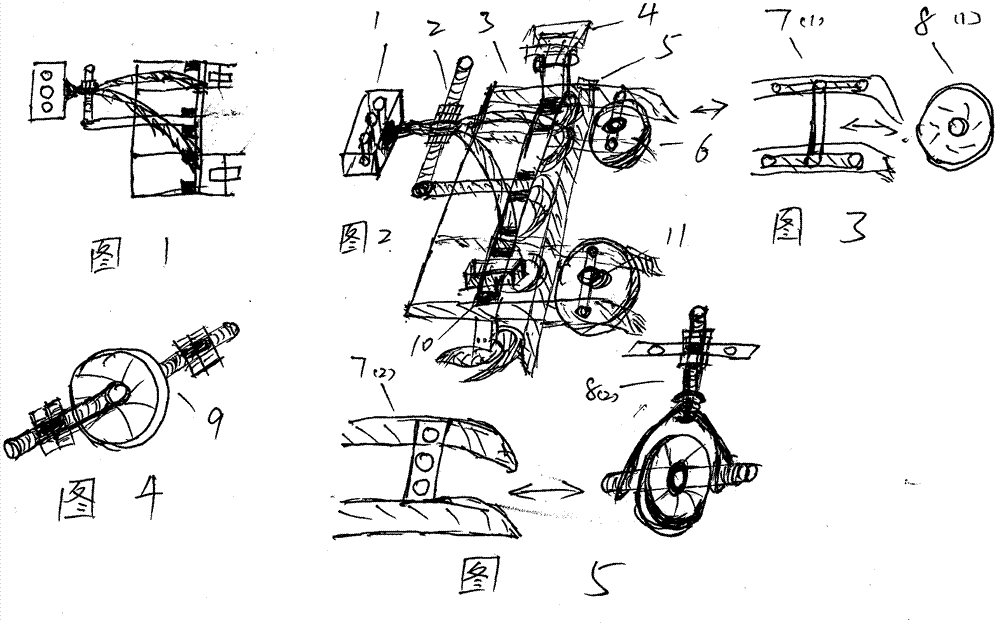

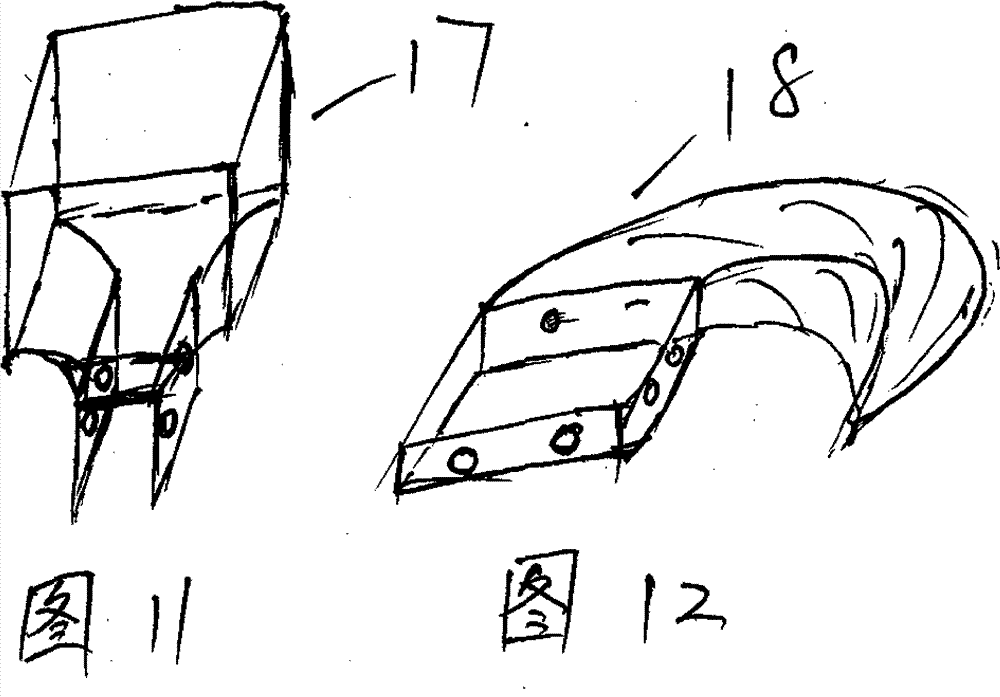

[0006] 1. According to the different types of crops to be sown, adjust the nut of the plow lifting mechanism (2) to adjust the depth of the plow to turn the soil and control the planting depth of the seeds.

[0007] 2. In the transverse adjustment mechanism 10 of the planter frame, the transverse distance between the plows is adjusted in the plow transverse distance adjustment groove, so as to control the seed planting row spacing.

[0008] 3. Hook the seeder connector (1) on the agricultural walking tractor or four-wheel machine, and start to try to turn the soil and sow. If the cover device is too high or too low to affect the sowing or cover the soil, it can be adjusted. Figure 5 , The tail of the planter frame can be lifted or adjusted to adjust the height of the full steering follower wheel to adapt to the sowing soil.

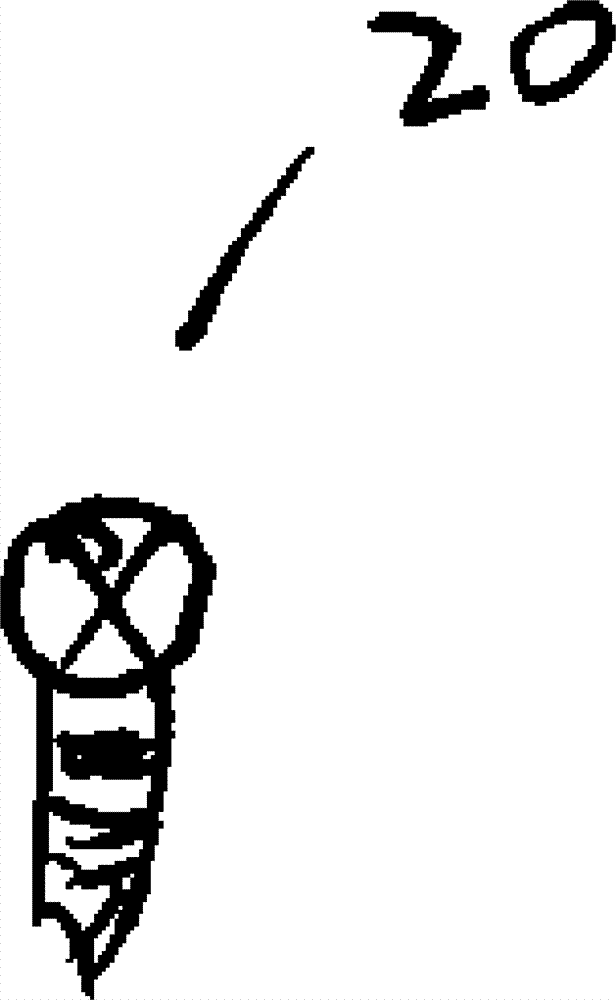

[0009] 4, when carrying out seeding, the crop plant spacing is controlled by the flow inserting sheet 19 of the funnel box, if the seed leakage of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com