High-speed EMU mop rinsing basin

A high-speed EMU and washing technology, which is used in railway car body parts, sanitary equipment, transportation and packaging, etc., can solve the problems of difficulty in taking out, accumulation of sediment, and difficulty in draining sewage, and achieves resistance to clogging and anti-fouling. Strong, low-cost maintenance and replacement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with specific drawings.

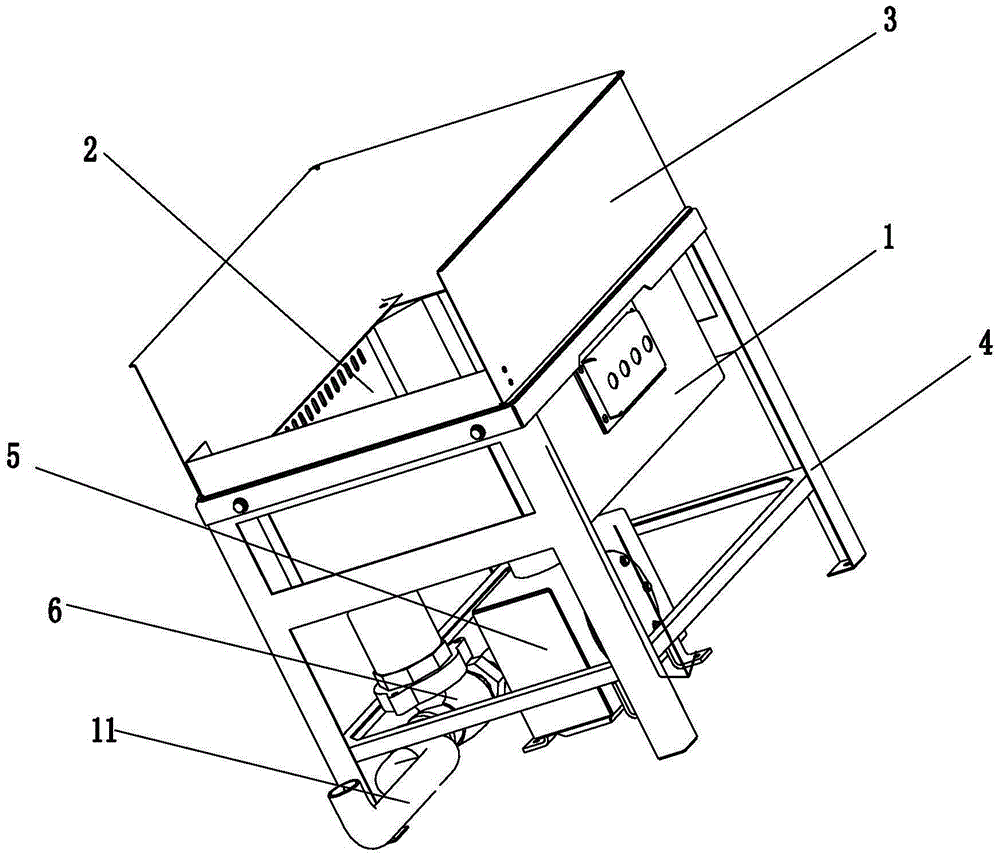

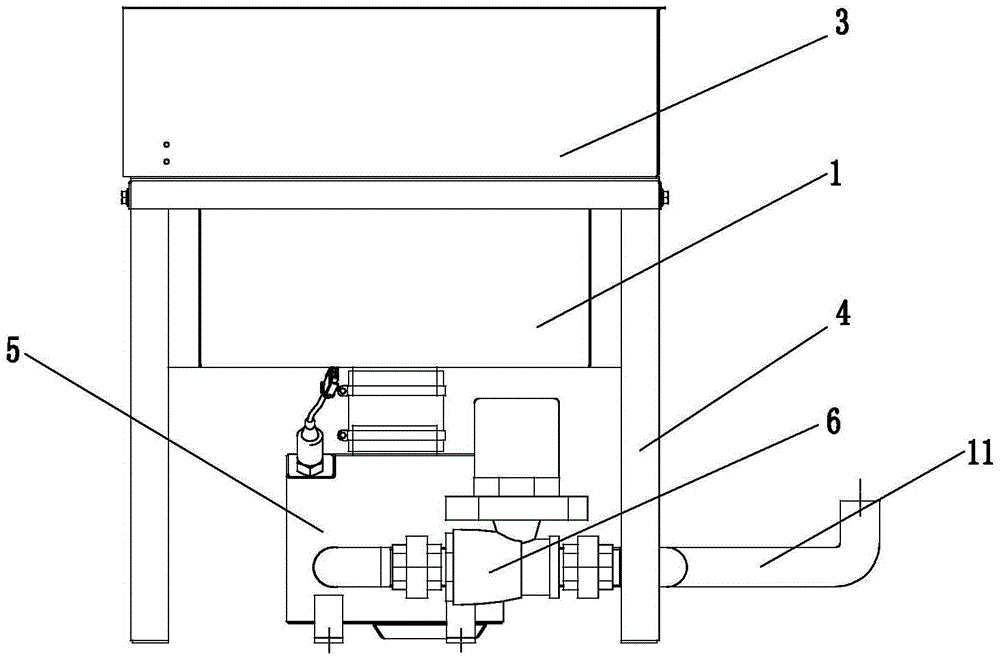

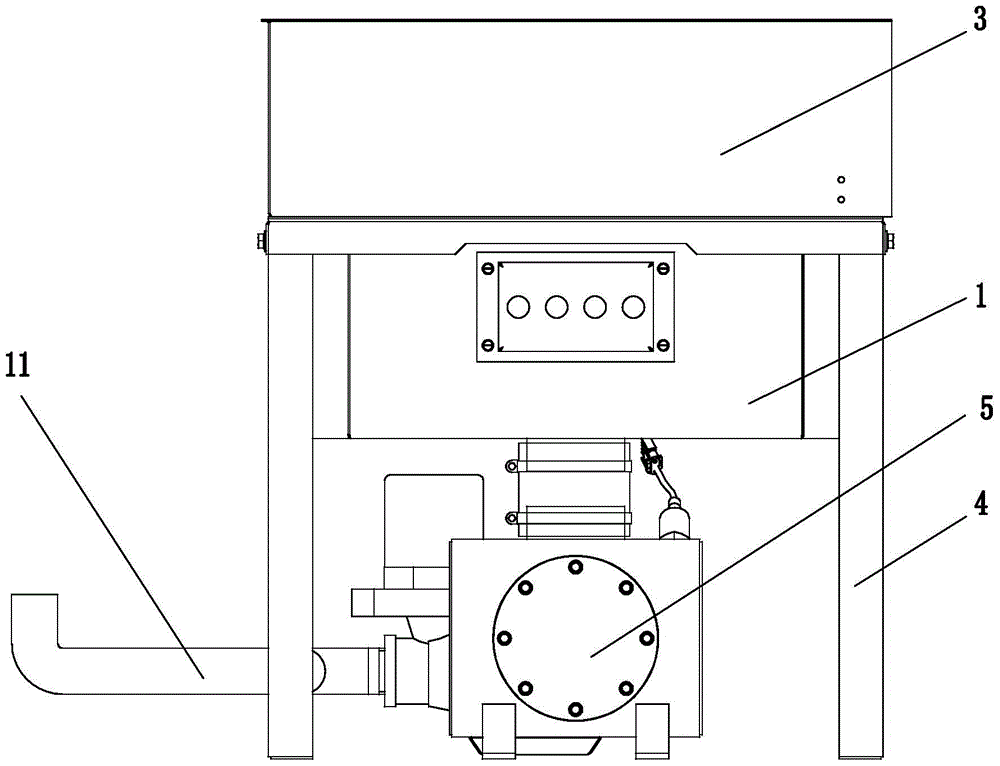

[0024] Such as Figure 1 to Figure 11 As shown: the high-speed EMU mop rinsing basin includes an outer basin 1, an inner basin 2, a waterproof board 3, a mounting seat 4, a gray water box 5, an electric ball valve 6, an anti-odor component 7, and a first water barrier 7-1 , the second water barrier 7-2, the water hole 8 of the inner basin, the overflow hole 9, the water hole 10 of the outer basin, the vacuum pipe 11, the liquid level sensor 12, the inspection door 13, the sewage tank 14, the charcoal bag 15, and the odor absorption Hole 16 etc.

[0025] Such as Figure 1 ~ Figure 3 Shown, the present invention comprises the rinsing basin assembly that is installed on the mounting base 4, and the edge of rinsing basin assembly is installed waterproof plate 3, and waterproof plate 3 can prevent sewage from overflowing and polluting the surrounding ground or polluting the perso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com