Conveying trolley

A technology for conveying trolleys and trolleys, which is applied in conveyors, mechanical conveyors, transportation and packaging, etc. It can solve the problems that parts are vulnerable to impact, wear, and noise, and achieve the effect of reliable on-line and smooth off-line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

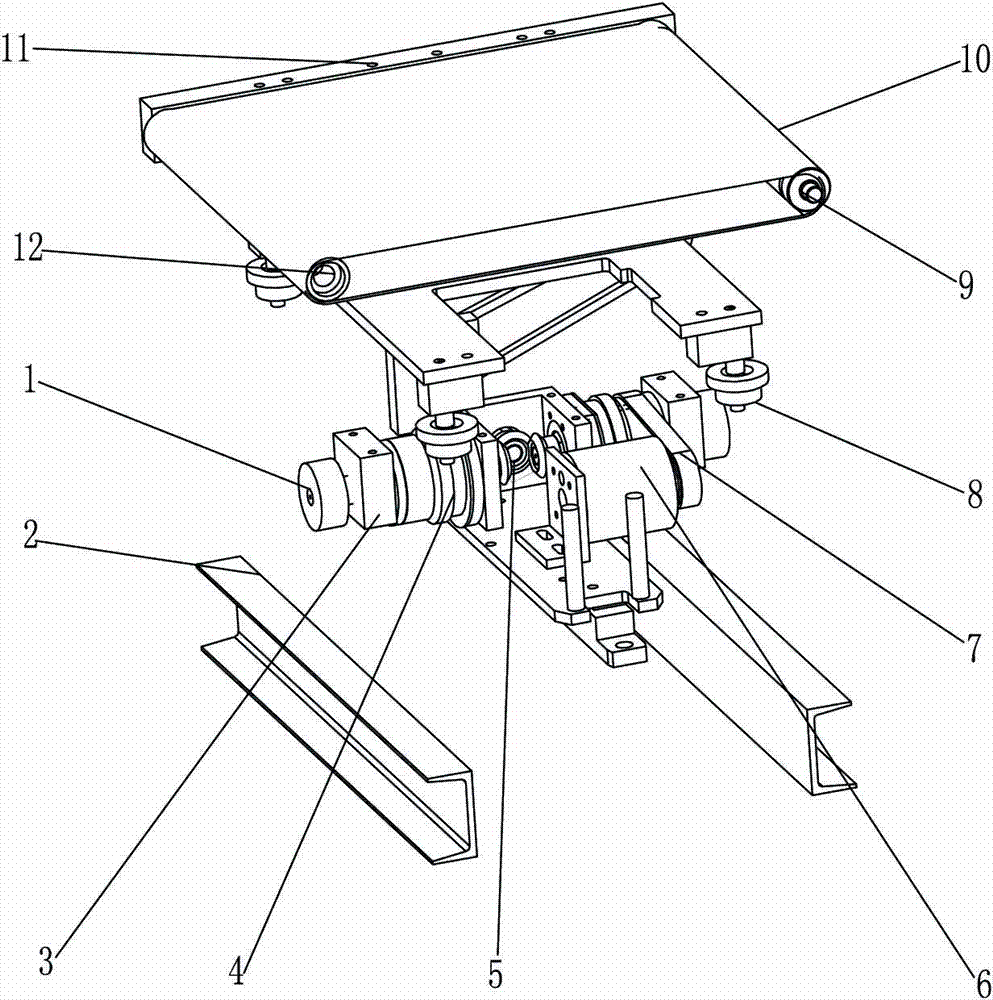

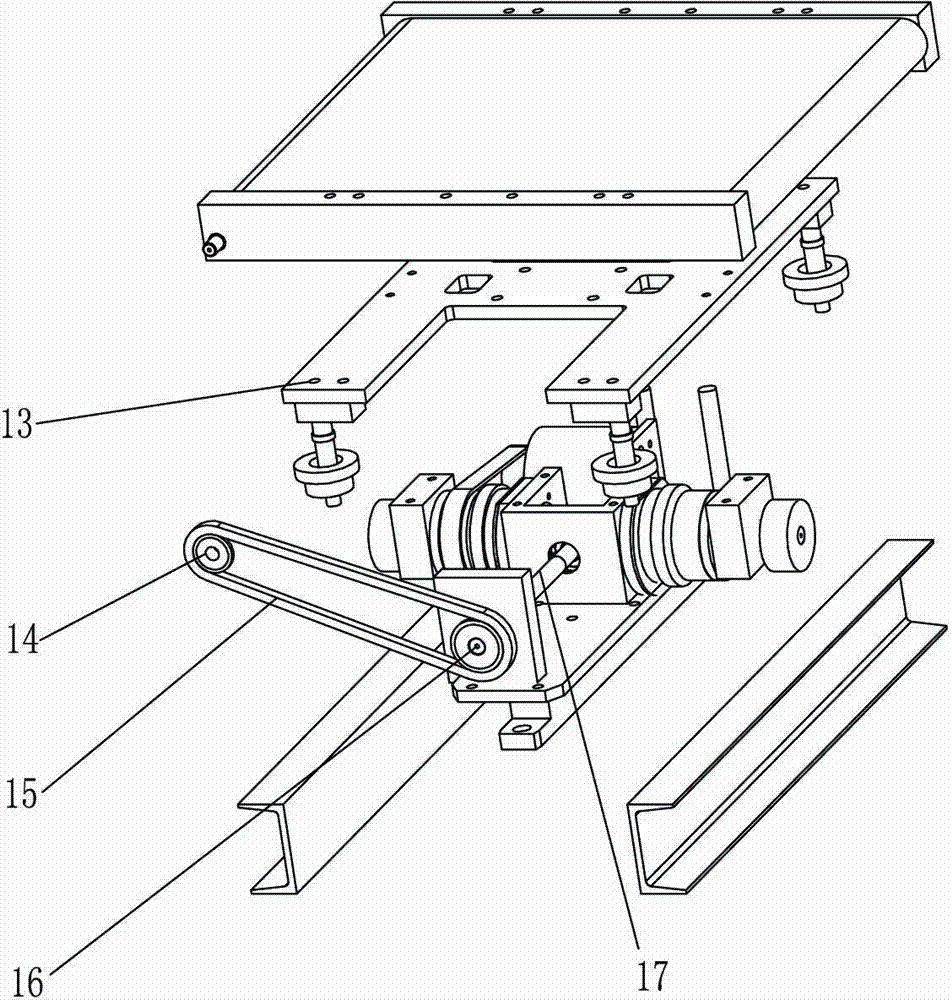

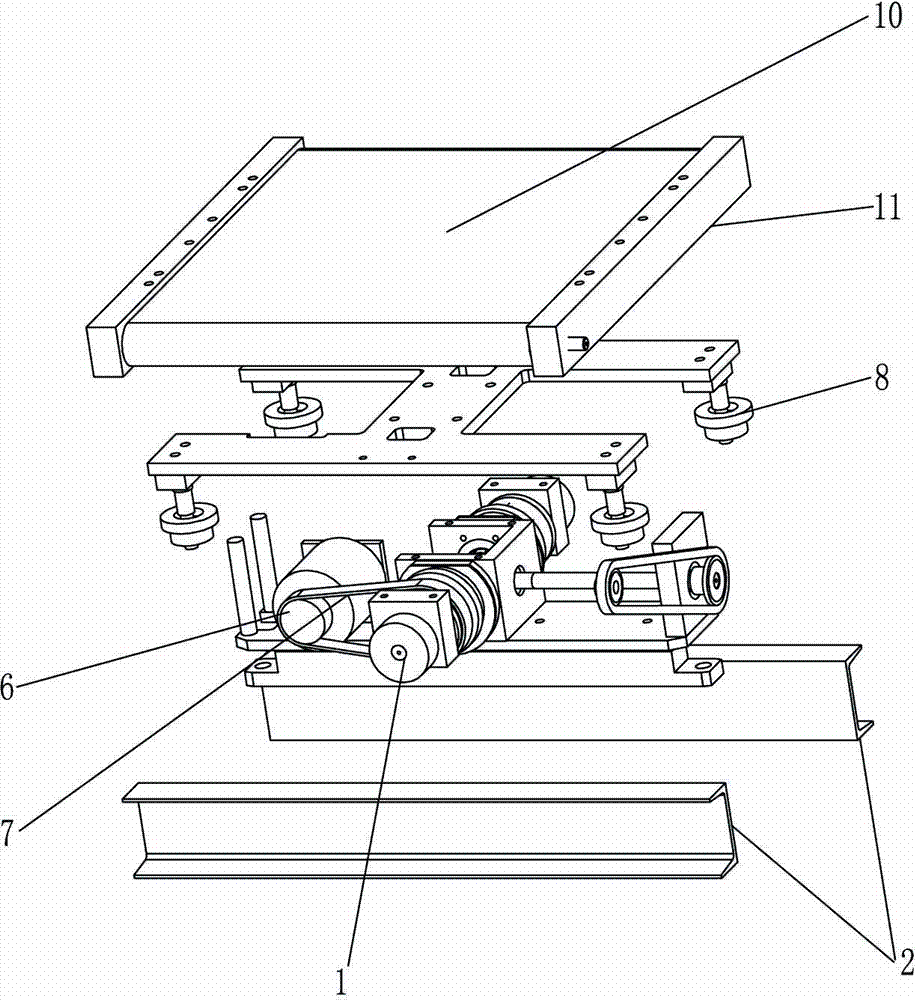

[0025] like figure 1 As shown in the figure, a conveying trolley includes a control module (not shown in the figure), a power shaft (not shown in the figure), a power transmission mechanism and a conveying mechanism which are sequentially connected by transmission, and the power shaft is connected with all the The power transmission mechanism is in driving connection, and the control module is electrically connected with the electromagnetic clutch 4 .

[0026] The conveying mechanism includes a trolley belt 10 , a driving roller 9 that drives the trolley belt 10 to rotate, and a driven roller 12 that cooperates with the trolley belt 10 and the driving roller 9 . Belt frames 11 are also provided on both sides of the conveying mechanism to accommodate and restrict the rotation of the trolley belt 10 within a predetermined range. The belt frame 11 is fixed on the belt frame fixing plate 13 .

[0027] The trolley traveling wheel 1 walks along the top surface of the guide rail 2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com