Hydraulic self-ploughing type sludge suction head

A mud suction head and self-cultivation technology, which is applied in the direction of mechanically driven excavators/dredgers, etc., to achieve the effects of reduced operating costs, high working efficiency, and increased torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation manners of the present invention will be further described in detail below in conjunction with the drawings and examples.

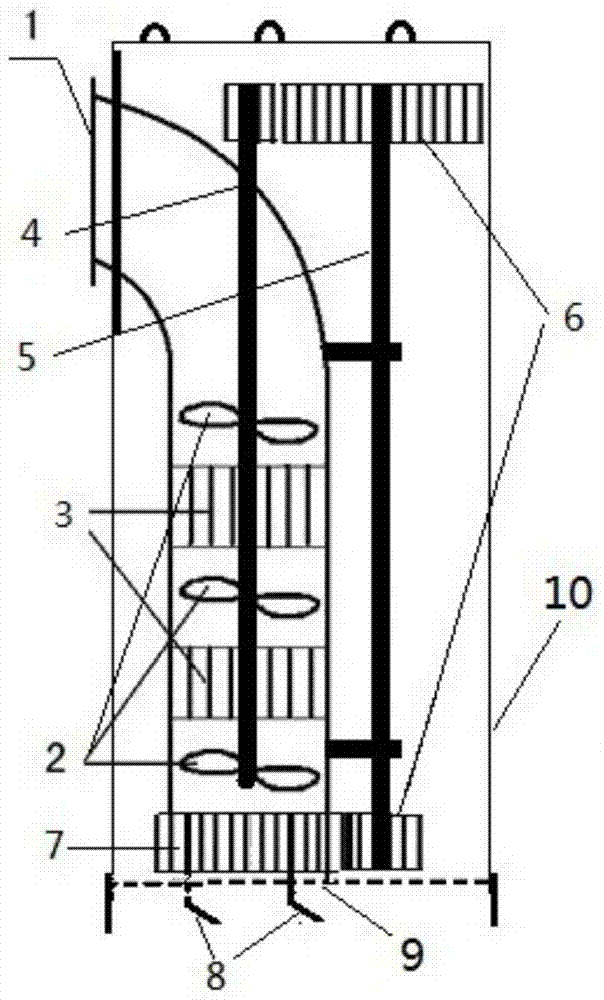

[0017] combine figure 1 , a hydraulic self-cultivation mud suction head proposed by the present invention, which includes a steel pipe (1), an impeller group (2), a rectifier (3), a driving shaft (4), a driven shaft (5), a gear set ( 6), bearing (7), plow (8), filter screen (9) and protective cover (10), wherein: the impeller group (2) and rectifier (3) are arranged in the steel pipe (1), and the rectifier (3) Fixed on the inner wall of the steel pipe (1), the drive shaft (4) passes through the bearing in the center of the rectifier (3), the gear set (6) is fixed on the drive shaft (4) and the driven shaft (5), The bearing (7) is embedded in the gear, the plow (8) is welded on the gear set (6), the filter screen (9) is set on the water inlet of the steel pipe (1), and the protective cover (10) encapsulates the abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com