Boiler power generation device and process

A boiler power generation and process technology, which is applied to machines/engines, non-flammable liquid/gas transportation, combustion methods, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

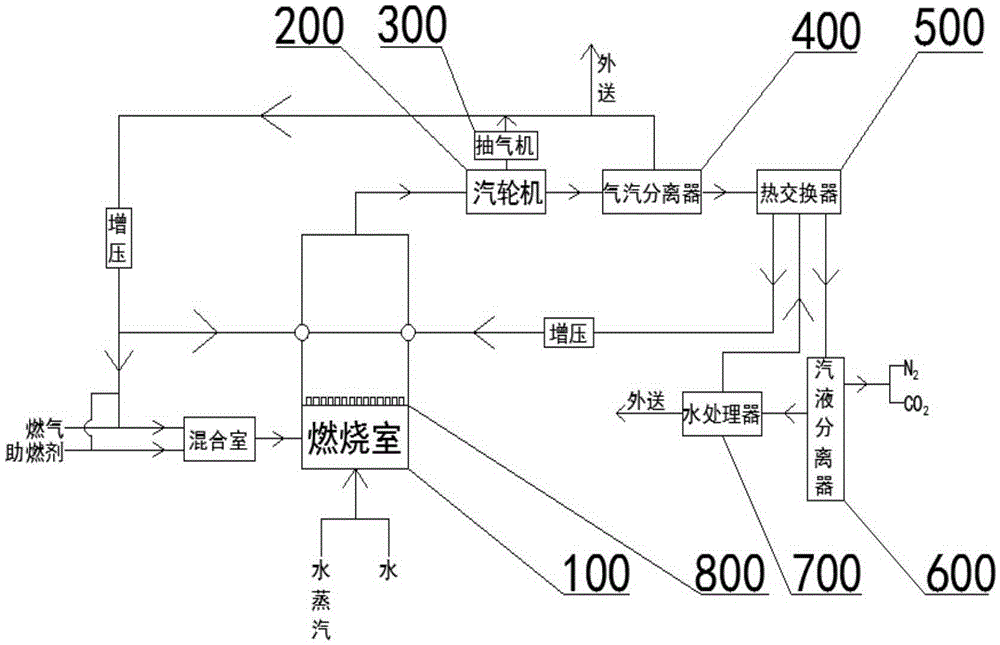

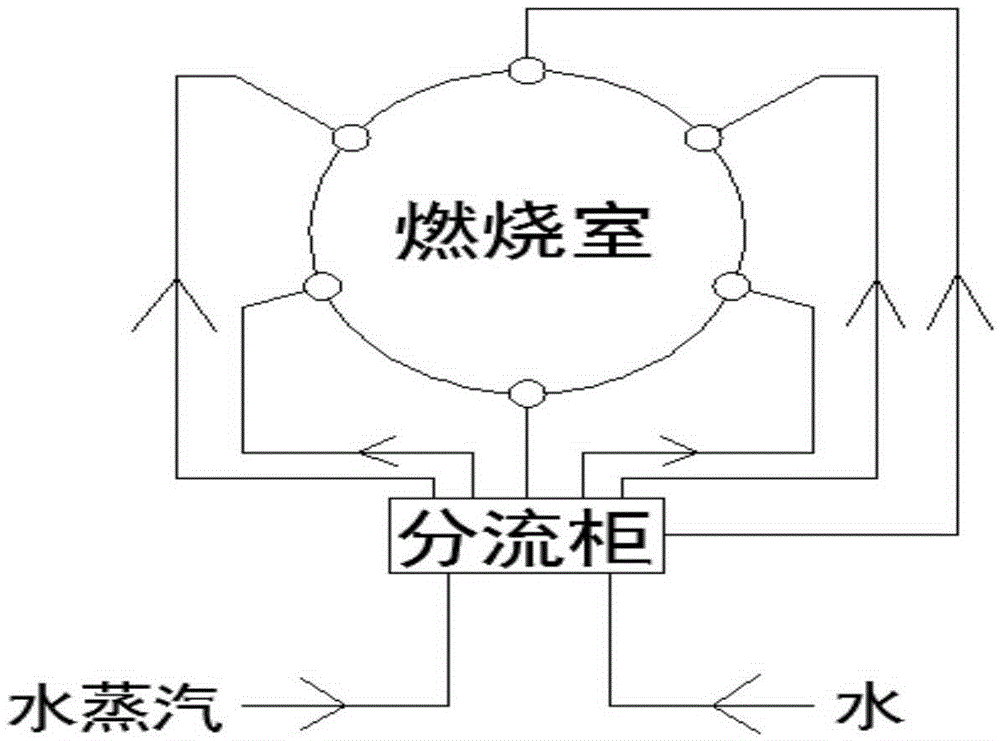

[0021] refer to Figure 1-4 , The boiler power generation device includes a combustion chamber 100, and the combustion chamber 100 is provided with an inlet for passing in water or steam. When the device works, gas is fed into the combustion chamber 100 first, and then water or water vapor is fed into to ignite the gas. Among them, the introduction of water or water vapor can adjust the temperature of the gas required for power generation, reduce the temperature of the gas after combustion, and increase the energy density.

[0022] Combustion chamber 100 is connected with steam turbine 200, steam turbine 200 is connected with air extractor 300 and gas-steam separator 400, gas-steam separator 400 is connected with heat exchanger 500, air extractor 300, gas-steam separator 400 and heat exchanger 500 are respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com