Online granary stored grain detection device, detection unit and pressure sensor measurement method

The technology of a pressure sensor and a detection device is applied in the field of grain storage and grain online detection device, which can solve the problems of the sensor being easily damaged, and achieve the effects of local structural stability, improving stability and preventing dislocation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

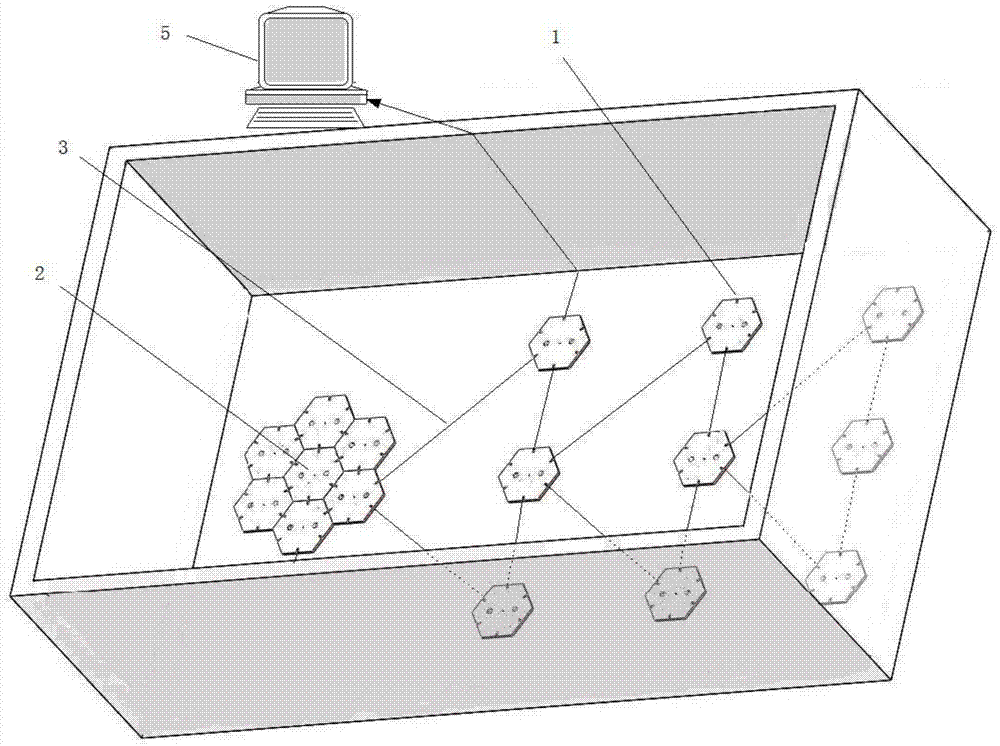

[0035] The invention provides a detection device. The basic scheme of the detection device is: an online detection device for the quantity of large-scale grain storage. A pressure sensor is arranged between them; the outer contour of the casing is in the shape of a regular hexagon or an equilateral triangle in a section perpendicular to the up and down direction.

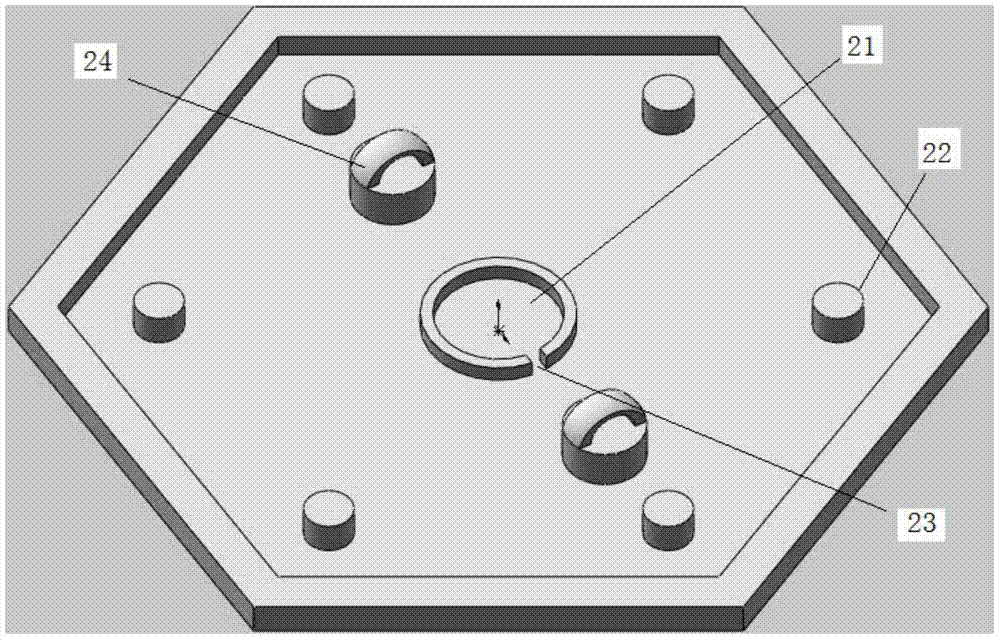

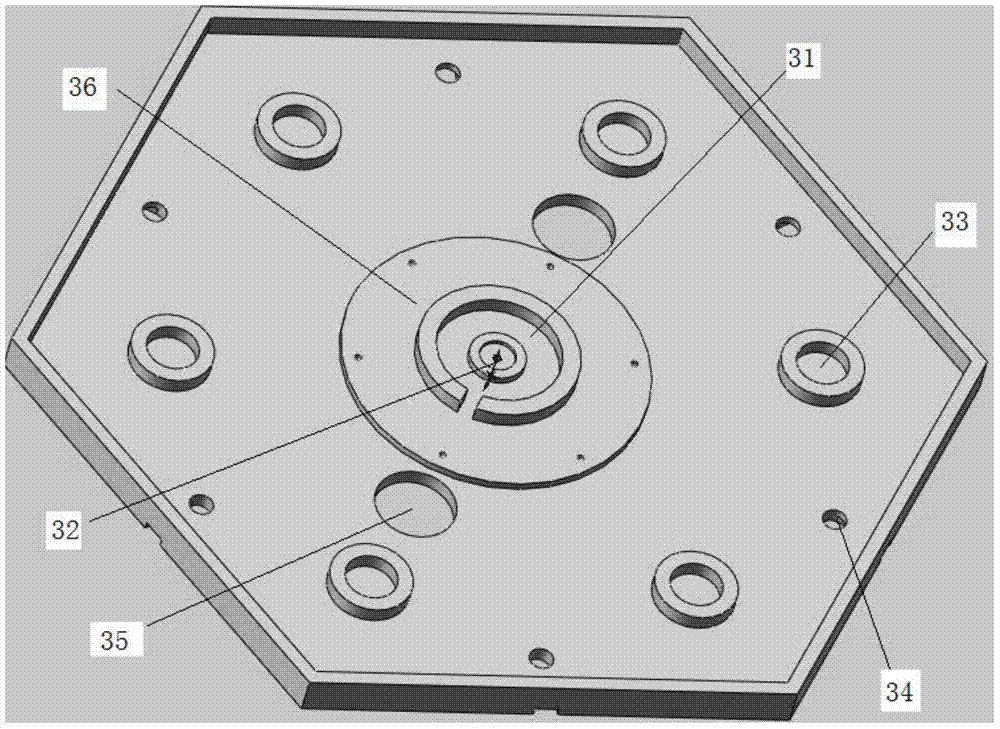

[0036] The bearing plate concentrates the large-area grain gravity acting on the bottom of the warehouse on the force-bearing surface of the pressure sensor with a smaller area.

[0037] Further, it is preferable to place the pressure sensor at the center of the entire device, that is, the pressure sensor is located in the center of the detection device, and the pressure sensor is evenly distributed with a number of positioning support guide rods in the circumferential direction; the positioning su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com