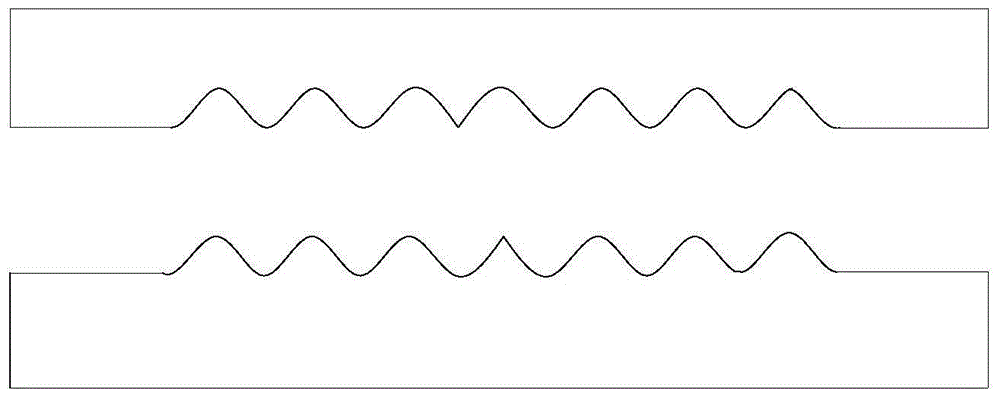

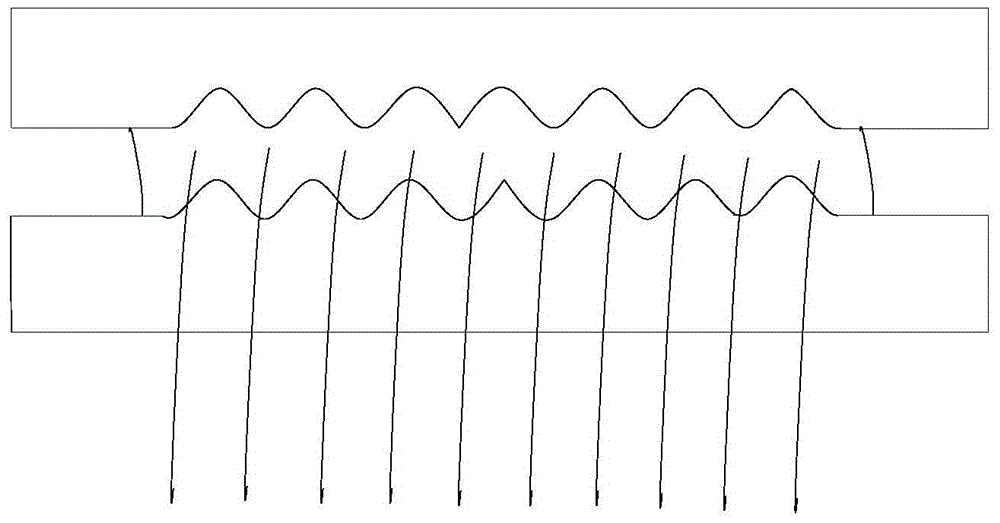

A method and testing machine for testing the dynamic adhesive holding force of rubber and steel wire

A technology of dynamic bonding and retention, applied in rubber testing and rubber fields, to achieve the effect of improving key performance, stable performance and increasing added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention is further described below with examples and comparative examples, but the scope of the present invention is not limited by these examples and comparative examples.

[0036] (1) Examples and comparative examples use the following instruments and equipment and assay methods to measure:

[0037] equipment:

[0038] 2.5L internal mixer, product of Czech Buzuluk company;

[0039] XK-160 open mill, product of Guangdong Zhanjiang Machinery Factory;

[0040] XLB-D type flat vulcanizing machine, product of Zhejiang Huzhou Dongfang Machinery Factory;

[0041] T2000 tensile machine, a product of Instron Corporation of the United States;

[0042] Rubber-steel wire dynamic adhesion testing machine, product of Yiweiyi Rubber Research Institute Co., Ltd.

[0043] test methods:

[0044] GB / T 6038-2006 Rubber test compound batching, mixing and vulcanization equipment and operating procedures

[0045] General procedure for rubber physical test method sample p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com