Compression heat generation detector and method thereof

A technology of compression heat generation and detectors, which is applied to instruments, calorimeters, and the use of stable tension/pressure to test the strength of materials, etc., can solve the problem of non-parallel to the upper surface under pressure, inaccurate compensation values, and inaccurate simulate the problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] Specific implementation plan

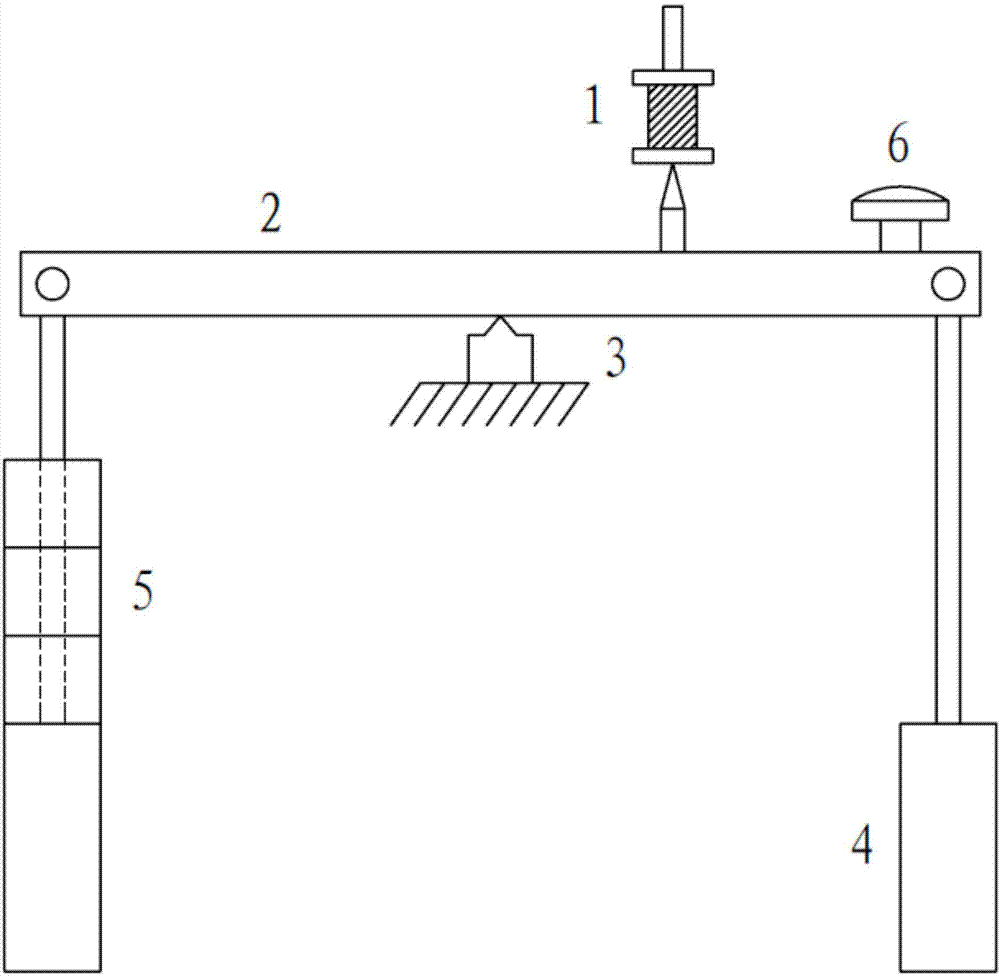

[0056] The invention includes one or more sets (optimally two sets) of detection units that can operate independently, and each independent detection unit includes a set of vertical compression device, a set of vertical compensation device and a core central temperature sensor synchronization device.

[0057] Such as Image 6 As shown, taking one set of detection units as an example, the vertical compression device and the vertical compensation device are respectively fixed on the top frame 8. The long guide shaft 17 in the vertical compression device is vertically guided along the corresponding hole in the top frame 8. The screw lower bearing box 23 and the upper bearing box 27 in the vertical compensation device are respectively fixed on the top frame 8, and similarly, the two short guide shafts 28 are also fixed on the top frame 8 respectively. The core center temperature sensor synchronization device is installed between the pressure plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com